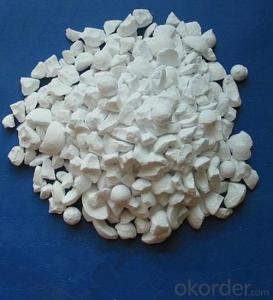

Raw Materials for Refractory - Tabular Alumina Materials

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Super high temperature shaft kiln sintered plate corundum that takes alumina as raw material is molded by milling and drying; on condition of quick warming and cooling in super high temperature shaft kiln, it becomes lots of tight column crystal and the dimension of crystal is among 30-200um; there are lots of alumina corundum that has high purity with lots of closed micro-holes.

Application

It is one kind of excellent insulation raw materials for fire-proof, porcelain and electric instruments; it is also excellent material for milling tool and polishing milling.

Specification(Please check the technical data in the below Format)

- Q: What are the fire protection standards of insulation materials?

- According to the three versions of GB8624 (1997,2006,2011), the fire rating of external walls can be basically divided into: A1-, A2-, B1-, B2-, B3-level. The detailed divisions are determined by many technical indicators. It is a very professional and technical long story. Please contact QINGDAO SHANFANG INSTRUMENT CO., LTD for detail information, they are specialized in manufacturing fire rating testing instruments of external walls.

- Q: What's the function of aluminium dihydrogen phosphate on the refractories?

- Mainly used for binder of high-temperature furnace refractory. Characteristics of liquid aluminum dihydrogen phosphate, castable. solid used for refractory spraying coating, chamotte, ceramic construction, which has high break resistance after being dried in 350-500 ° C, phosphate bricks. Characteristics of the solid aluminum dihydrogen phosphate, binding agent used for castable and casting industry: together with the refractory aggregate, ramming mixes at room temperature: Easy to mix, crush resistance, hydration resistance, chamotte, will not become soft even if soaked or boiling in water, molding. Liquid use refractory spraying coating, mainly used for corundum, chrome corundum water gap in refractory industry. The production of chrome aluminum zirconium corundum brick for water-coal-slurry gasifier is especially suitable for site construction applications mainly used for the electrical industry, high-temperature kiln and furnace, hardener, after mixing between 90-110 ° C for 4-24 hours at a constant temperature, forming strong bonding strength, electrical insulation, heat treatment resistance furnace

- Q: What are the refractory materials above 1000℃

- I have no idea what field you are in, and I am skillful at making refractory materials, because this is my job. You can send me an email informing your purpose, here is my email address .

- Q: What is the use of refractory?

- Some is insulated for personnel safety, some is to save heat loss and conserve energy, and some is used as lining of kilns. Because of its light weight, I recommand it to you and I am engeged in ceramic fiber, just an advertisement.

- Q: What material is refractory material?

- alumina refractory concrete, silica brick clay brick, metal ceramic, high temperature machine coating fiber reinforced ceramics, diatomite product, asbestos products, insulation board refractory. The definition of refractory can be searched in the website.

- Q: How to choose construction external wall thermal insulation and fireproofing materials?

- Now external wall insulation decoration one board is more popular thermal insulation material. Low-carbon energy-saving insulation decoration board combine two constructions (decoration, insulation) into one, saving nearly ten processes,and construction period. Compared with conventional thermal insulation methods, it can increase construction efficiency one time by shortening 60% of the construction period. It integrates low carbon, energy conservation, decoration, fireproof and building aesthetic effect by combining like-dissolving-like binding system installation and bump fixed system, and under long-term cooperation of air handling system and waterproof system. It has excellent outdoor weather resistance, colour?retention, alkali?resistance, water resistance, scrubbing resistance, crack resistance and temperature change resistance, wear resistance, collion resistance and the paint film is firm and durable, with strong adhesive force and mould proof effect. It can provide all-dimensional thermal insulation, decoration, low carbon and energy conservation and fire prevention for construction projects.

- Q: Does refractory belong to metallurgical auxiliary materials?

- Refractory is widely used in industrial circle, such as metallurgy, chemical industry, petroleum, mechanical manufacturing, silicate and power, and its coonsumption is the maximum in metallurgy, accounting for 50% to 60% in total output. In order to improve slag-corrosion resistance of furnace lining, usually choose carbon-containing refractory. Refractory of various furnace lining are respectively: For the body, it is clay brick; as for the lower part, bosh and middle, it is SiC brick; for furnace bottom, it is carbon brick. Lattice brick is an important refractory product used in air heating furnace and regenerative chamber. Refractory is widely used in metallurgy. In order to improve slag-corrosion resistance of lining. Central line in tuyere and hearth are high-alumina brick. Refractory consumption is the maximum in metallurgy, accounting for 50% to 60% in total output. For the bosh and middle, it is SiC brick. In order to improve its thermal storage capacity: The furnace stack is clay brick. It is defined as refractory where the physical and chemical properties allows its use in high temperature environments; The lower furnace body

- Q: It the Special Fire-Proof Material belonged to ceramics? Is there a national standard of the Special Fire-Proof Material?

- The fiber and reinforcing material of the metal ceramic is also belonged to the Special Fire-Proof Material. ~~~~GB is too much trouble, GB online should ~~~ Lei Bao Refractories for you. The high temperature inorganic coating. 5. The refractory compound. 3. The high melting point oxide. You can search it on the internet according to the classification~~~~ The special refractories can be divided into five categories: 1. metal ceramic

- Q: Introduction to refractory material

- The best way to learn is on-site contact. If for produing purpose, it is better to ask teh leader of a plant. If for application, go to steel mill (cement plant, glassworks, etc.) to learn and look up information. Theory alone is of no help.

- Q: What are the grades of refractory exterior wall thermal insulation materials?

- Classification of fire rating of extrior thermal insulation materials 1, According to national standard GB8624-97, the combustion performance of building materials are divided into the following grades A level: Incombustible building materials: Materials hardly burn. B1 class: Flame-retardant building materials: Flame-retardant material has good flame resistance. In case of fire in the air or at high temperature, it is difficult to catch fire and the fire will not spread quickly. And when the combustion source is removed, the burning will stop immediately. B2 Class: Combustible building materials: Combustible materials have a certain flame retardancy. In case of fire in the air or at high temperature, it will immediately burst into flames and it is easily to spread fire, such as wooden column, wooden roof truss, wooden beams and wooden stairs, etc. B3 level: Inflammable building materials: It has no flame retardant effect, and it is extremely inflammable, and the risk of fire is high. Classification of exterior wall thermal insulation materials according to fire rating: 1. Thermal insulation materials with A-level combustion performance Rock wool, glass wool, foam glass, foamed ceramic, foam cement, hole-closed perlite, etc. 2, Thermal insulation materials with B1-level combustion performance: Extruded polystyrene board (XPS) after special treatment / polyurethane (PU) after special treatment, phenolic aldehyde, gelatine powder polystyrene granule, and etc. 3. Thermal insulation materials with B2-level combustion performance: Molded polystyrene board (EPS), extruded polystyrene board (XPS), polyurethane (PU), polyethylene (PE), etc.

Send your message to us

Raw Materials for Refractory - Tabular Alumina Materials

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords