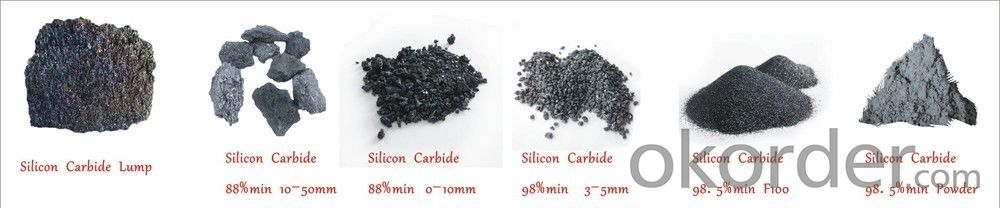

Raw Materials for Refractory - SIC Silicon Carbide Made in China for Abrasive and Refractory

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Henan, China (Mainland) | Brand Name: | CNBM | Model Number: | silicon carbide |

| Material: | SIC | Usage: | Polishing lapping refractory metallurgical | Abrasive Grain Sizes: | 12-3000# |

| Color: | Black and green | Name: | SIC | Application: | Polishing lapping refractory metallurgical |

| PAYMENT TERM: | T/T | Sample: | Provide | Package: | Jumbo Bag |

| Hardness: | 9.15 Mosh | Feature: | High Density | Quality: | Excellent |

Packaging & Delivery

| Packaging Details: | Silicon Carbide Powder:25kg bags loaded in 1 ton jumbo bags Silicon Carbide Lump: 1 ton loose in Jumbo bags. Or as customer request. |

| Delivery Detail: | 20 days after buyer's instruction |

Black Silicon Carbide is made by a precision water classification process and air flow classification using material that is produced from the reaction between high purity silica sand and petroleum coke in a resistance-type furnace. Measuring 9.0+ on the MOHS scale of hardness, silicon carbide is one of the hardest abrasives known in the industry. The inherent friability of the sharp crystalline structure assures the continuous exposure of new cutting edges, which produces a faster and cleaner cutting performance.

Green silicon carbide is produced as the same type as the black silicon carbide,except the different raw materials. It’s crystallization have higher purity and hardness.Green silicon carbide is suitable for processing hard alloy,metallic

and non-metallic material with hard and brittle feature such as copper, brass, aluminum,magnesium,jewel, optical glass, ceramics, etc. Super micro-power of it is also a kind of ceramics material.

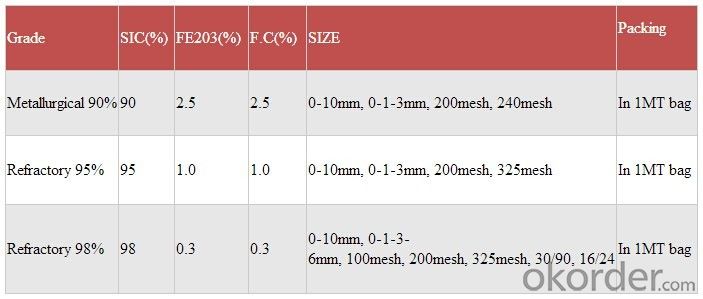

Chemical composition (%)

Grit size | SiC | F.C | Fe2O3 |

20# - 90# | ≥99.5 | <0.20< span=""> | ≤0.20 |

100# -180# | ≥98.5 | <0.25< span=""> | ≤0.50 |

220# - 240# | ≥97.5 | <0.25< span=""> | ≤0.70 |

F230 F360 | ≥97.5 | <0.30< span=""> | ≤0.70 |

F400 F600 | ≥95.5 | <0.30< span=""> | ≤0.70 |

F800 F1200 | ≥94.0 | <0.50< span=""> | ≤0.70 |

COMPANY PROFILE

CNBM International Corporation (CNBM International) is the most important trading platform of CNBM Group Corporation, a state-owned company under the direct supervision of State-owned Assets Supervision and Administration Commission of the State Council.

Since 2004, the trading volume of CNBM International has been doubled in 5 successive years owing to the support of superior corporations and effort of all staff. Meanwhile, we have established strategic partnerships with hundreds of domestic manufacturers and sound business relations with clients from over 120 countries. Currently, we have wholly-owned overseas subsidiaries and branches in 5 countries with a view to realize localization, which also represents an essential progress in our globalization target.

In line with the business, CNBM International launched E-business platform Okorder.com.

Our goal is to transform CNBM International into the global leading brand in building materials industry within 3 to 5 years through innovation and reform, by strengthening the overall management of supply chain, developing and cultivating both domestic and overseas market, improving the procedure and information system, enhancing the ability to organize resources and to provide value-added services under a professional team and a learning organization.

With the advantages in Cement, Composite Materials, New Building Materials and Engineering, we mainly concentrate on coal, steel and construction equipments and give priority to solar and wind energy development simultaneously utilizing our competitive position on traditional building materials to achieve sales revenue of RMB10 Billion in 2013.

CNBM International is highly recognized by its business partners and clients all over the world and has obtained rapid development under the spirit of win-win. We will carry on the mutual beneficial, innovative and revolutionary trading structure as we did before, create value for our employees, share holders and clients and benefit the whole society in our future development.

Our Service:

1. Your inquiry related to our products or prices will be replied in 24hours.

2. Manufacturer with large capacity, ensure the fast production cycle after confirmed the order.

3. Our professional technicians will answer your entire enquiry in patient.

4. To meet the refractory solutions, we can serve as your instructions.

5. Protection of sales area and private information for our entire customer.

If you’ve kind enquiries, please don’t hesitate to let us know. ^_^

- Q: What is unshaped refractory?

- Unshaped refractory is a mixture made of aggregate and powder, binder or other admixture. It can be used directly or after proper liquid mixing. The material is a new type of refractory material after calcination, the refractoriness of not less than 1580 DEG C unshaped refractory materials by various varieties, production method and use method thereof can be divided into concrete, pouring material, plastic, ramming material, gunning, casting material, coating material, dry ramming material fire, mud, all kinds of repairing materials (with asphalt surface patch charge, Ma Dingsha) also do not belong to the shape of the column.

- Q: What kind of refractory materials should be used for the intermediate frequency furnace to smelt manganese?

- I’d like to make supplements to upstairs that aluminum silicate refractory materials should be needed considering heat insulation.

- Q: How to determine the fire resistance rating of the aluminium-plastic?panel?

- Fire rating of the best aluminium-plastic?panel in the current market is B1 class, and its grade classifications can refer to the national standard. I have examined factories and tested the fireproof effect of the fire-proof plate myself by burning it, and I have found that the fire-proof plate of Jinwei Aluminium-plastic?Panel in Linyi is really good in quality and fire prevention. In other words, from the single point of fire rating, the corresponding fire rating of the called fireproof aluminum (plastic) composite panel should be at least B class, and for A2 class fireproof aluminum composite panel, its core material currently doesn't include plastic element, so it's called aluminum composite panel which is of inorganic core material. If the ordinary aluminum-plastic panel is classified according to the fire-proof building material, it will belong to that of lower level. For aluminum-pastic panel used in business premises, it is required to reach the grade of flame retardant material or above this in fire prevention. It is expressly stipulated that its fire rating should be A2 class in public places.

- Q: what's the classification of fireproof materials?

- Fireproof materials are used in construction, in various forms and it has played an absolute role in modern fireproofing, common fireproofing materials include fireproof?panel, fire door, fireproofing glass, fire?retardant?coating, fireproof bag,etc Or the material itself has a high temperature resistance, heat-resistant, flame-retardant properties. Most of them are used for the construction industry.

- Q: What refractory material does cupola lining use?

- In order to improve the service life of the lower wall and the bottom leather, dense and high alumina brick can be used for masonry. The front furnace is composed of the bottom, the wall and the top. The top of the furnace is vaulted or hanging flat roof. The front furnace body is usually made of clay brick and high alumina brick, and the bottom work floor is rammed with ramming material. The material is the same as that of cupola furnace. The bridge and the front guard taphole, slag hole and other parts due to erosion by high temperature molten iron and slag erosion, lower service life, frequent repairs. Large blast furnace adopts hot blast or oxygen enriched blast, which has higher temperature and higher production capacity... The damage is faster, and it is hard to maintain production by using clay brick or high alumina brick. Should be used aluminum, carbon or corundum refractory silicon carbide castables pouring or tamping, so that the integrity of good, high strength, corrosion resistance, and therefore significantly improved service life, generally up to one year or so. Refractory materials, including chimneys and spark traps, are used in other parts of the cupola. The chimney and the cupola shaft directly connected with the shell made of steel plate, lined with ordinary clay brick, can also be used ordinary refractory castable pouring. The chimney is provided with a furnace heat exchanger, which can preheat the air to 300~500 DEG C, and the spark collector is used for catching the hot coke and dust particles brought out in the flue gas. The chimney at the top of the reflector (cover) by plate welding, can also be used to cast iron, its lining refractory coating or spraying paint.

- Q: What are the classifications of refractory? Which category does steel ladle castable belong to?

- Silmo brick, alumina-magnesia brick; 2. coke oven, aluminum silicate... 8 categories)& nbsp, teeming ladle, glass furnace ...... 7 categories) high alumina refractory products (blast furnace, electric furnace, cement kiln, magnesia, glass furnace; 3. high alumina refractory mortar (high alumina, glass kiln ...... 6 categories) special refractory products (magnesia-carbon bricks, aluminum-carbon bricks, MgO-C, shapeless refractory products& nbsp, light weight, sliding plate bricks, cement kilns: There are 26 categories in refractory products, clay, calcium silicate, ceramsite lightweight... 10 categories) & nbsp, air heating furnace, sheets; 1 refractory castable (alumina-magnesia, blocks, resistance furnace... 11 categories) alkaline refractory products (magnesia. First, thermal insulation refractory products (ceramic fiber; clay, diatomaceous earth, steel fibre reinforcement...14 categories) & nbsp, silicon carbide brick ...... 19 categories) Second, China is the largest refractory production country in the world, clay, non-water cannons mud, converter, siliceous, teeming ladle, profiled) siliceous refractory products (coke oven, dense shaped refractory products (all kinds of bricks, electric furnace roof, glass kiln ...... 5 categories) clay refractory products (blast furnace, high alumina ...... 4 categories) three

- Q: Can anyone say something about what A-level fire-proof decorative material is?

- Combustion performance rates of decoration materials ratess combustion performance of decoration materials A incombustible B1 flame retardancy B2 flammability B3 high flammability The B1 rate combustion performance of gypsum plaster board and mineral wool acoustic panel absorber installed on steel joist can be used as A-level decoration materials. Inorganic decorative coating applied on the A level substrate can be used as A level decoration materials. Hope you adopt

- Q: Who knows what kind of fire protection material is better?

- Characteristic of polyurethane rigid foam thermal insulation decorative composite board: (1) ultra high cost performance, increased property's selling point (high cost performance) new model of thermal insulation material, excellent thermal insulation properties, elegant decorative effect, 50 years of service life, reduce maintenance costs and social waste. (2) it overcomes defects of traditional insulation technology (to solve the freezing and thawing, veneer cracking and shedding) traditional benzene board, the phenomenon of freezing and thawing that is easily appear in plastic extruded sheet, paint finish is easy to crack; its veneer facing can easily fall off; thermal insulation materials and wall are poorly adhered, easy off the whole. There is a themal bridge in dry hanging wall. (the characteristics of polyurethane composite board)

- Q: who knows the technology of fireproofing material?

- 1, dealing mould, scrape and clean the thick liquid on the surface of mould with tin-coated steel scraper blade or plaster tool. 2, adjust laminator, according to the thickness of fireproof?panel, adjust each roller, keep them parallel. 3, ingredient, according to the requirements of recipe, stir the raw materials uniform with agitator. (usually we should add bittern firstly, stir it with modifying agent for 5 minutes, then add filler and stir for 2-3 minutes, finally add grogs and stir it to uniform) note: the stirring speed should be kept in 60-80 r/min. 4, place the cloth, place a layer of non-woven fabric and two layers of glass fiber fabric (mechanical spread fabric). 5, flitch, place the materials after compounding and stirring into stop gauge of laminator, then you can start up and produce continuously, it's finished product after finishing. note: the distance between two templates is 2-4mm.

- Q: Who knows how many poured refactory material are there?

- Pouring refractory material can be classified into the followings according to the body density: Heavy (> 2.0g\cm3), medium heavy (1.0-2.0g\cm3), light (0.4-1.0g\cm3); by binding agent: Combination of hydration, chemical binding, condensation, hydration and condensation: Clay, high alumina, silica, magnesia, alumina magnesia, magnesium and chromium, magnesium zirconium, silicon carbide etc.. Clay brick, high alumina brick, bead brick, silica brick, light mullite, alumina hollow spherical brick, oxidation zirconium hollow spherical brick, corundum brick, magnesia brick, magnesia brick, magnesia alumina spinel brick, magnesia chrome brick and so on

Send your message to us

Raw Materials for Refractory - SIC Silicon Carbide Made in China for Abrasive and Refractory

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords