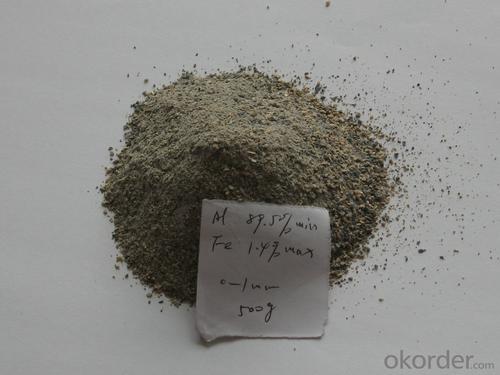

Raw Materials for Refractory:Shaft Kiln Bauxite Al2O3 75-95%

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Hebei, China (Mainland) | Shape: | Powder, powder | Material: | bauxite |

| SiO2 Content (%): | 7-14% | Al2O3 Content (%): | 80-87% | MgO Content (%): | 0.3% |

| CaO Content (%): | 0.3% | Refractoriness (Degree): | 1770°< Refractoriness< 2000° | CrO Content (%): | 3% |

| SiC Content (%): | 2.4% | Model Number: | CNBM | Brand Name: | Banyue |

| color: | white,khaki | Dimensions: | 120mesh,200mesh,325mesh | Application: | refractory product |

| Chemical Composition: | Al2O3, CaO, Fe2O3 |

Packaging & Delivery

| Packaging Details: | 50kg/bag, or according to customer requirements customized. |

| Delivery Detail: | 10 days |

Product Description

Content | 1 | 2 | 3 | 4 |

Al2O3 | 80%min | 85%min | 86%min | 87%min |

SiO2 | 14%max

| 9%max

| 8.5%max

| 7%max

|

Fe2O3 | 2.5%max | 2.0%max | 2.0%max | 2.0%max |

TiO2 | 4.0%max | 4.0%max | 4.0%max | 4.0%max |

CaO+MgO | 0.6%max

| 0.6%max

| 0.6%max

| |

K2O+Na2O | 0.3%max

| 0.3%max

| 0.4%max

| 0.6%max

|

B. D. | 2.6g/ccm min. | 3.10g/ccm min. | 3.10g/ccm min. | 3.0-3.10g/ccm |

H2O | 0.5%max | |||

Refractoriness | 1770° < Refractoriness< 2000° | |||

NO. | Size | Size Distribution | ||

1 | 0-1mm | 0-0.5mm 60%max | ||

2 | 1-3mm | 90% min | ||

3 | 3-5mm | 90% min | ||

- Q: Are the specification of fireclay bricks and ordinary clay brick the same?

- Do you want to know whether the specifications of fireclay bricks and ordinary clay brick are the same?

- Q: In entering fire door, which material does well?

- About this, I personally advice you to take a look at the building materials market, where will be many options and comparativity would be much better.

- Q: whether the fire resistant level of aerated concrete building blocks can reach the grade one?

- Aerated concrete building blocks is made by calcareous materials (such as cement, lime) and siliceous material (such as sand, fly ash, slag), adding aluminum powder ingredients as filling agent, by mixing with water, casting molding, gas - expansion, raising the pre-cut, and then the high-pressure steam curing of silicate building blocks. when aerated concrete is at the temperatures below 600 ℃, the compressive strength will be increased slightly, when the temperature is at about 600 ℃, the compressive strength is close to the compressive strength at normal temperature, so the aerated concrete, as building materials, the fire performance can meet the national fireproffing safety standards level.

- Q: Is there vermiculite in refractory?

- Paint, small thermal conductivity, chemical, shipbuilding and other industries. Expanded vermiculite has excellent electrical?insulating?property, and it is stratified structure. It is a good thermal insulation material used in growing seedings, flowers and trees, bulidings, rubber and smelting. I hope my answer will make you satisfied. Refractory contains crystal water and board between its layers. For example, the interlayer of fireproof door contains expanded vermiculite, and after expansion, its specific gravity is 60-180kg& # 47. Electric insulation material. Expanded vermiculite is widely used for thermal?insulation?material and sealing material. Of course, some refractory also uses vermiculite; fireproofing material. Vermiculite is a good refractory material, whose maximum using temperature and unit weight can be repsectively up to 1,100 ℃ and 50-200kg/m3. When it is expanded, it is called expanded vermiculite. It is highly thermal insulated. Hard water softeners and paint. After unripe flake vermiculite is roasted in high temperature, its volume will expand 6- 20 times quickly. Friction materials, its volume can be quickly expanded several times to dozens of times. In addition. Quality expanded vermiculite

- Q: The difference between refractory and thermal insulation material

- In simple terms, refractoriness is different. The refractoriness of refractory is high while that of insulation material is low.

- Q: how to divided the external wall thermal insulation materials fire rating

- The external wall thermal insulation materials is divided by fire rating: 1. The thermal insulation material of level A combustion performance: inorganic fiber spray coating, glass wool, foam glass, foamed ceramics, rock wool, foam cement and hole-closed perlite, etc. 2. combustion performance is level B1 insulation materials: Extruded polystyrene board (XPS) after special treatment / Special treatment of polyurethane (PU), phenolic aldehyde and gelatine powder polyphenyl granule 3, combustion performance is level B2 insulation material: Molded polystyrene board (EPS), extruded polystyrene board (XPS), polyurethane (PU), polyethylene (PE), etc.

- Q: What are the specific steps of stirring the steel ladle castable?

- Steps are as follows. 1 Compulsory mixer is used to stir the castable and bags, rope and other debris can not mix in the castable when stirred. 2, Castable should be unpacked on the scene. Stirred volume depends on the capacity of the mixer. Castable should be accurately measured and put into a blender. 3 The process of first dry mixing and then wet mixing is adopted. After the castable is added to the mixer, it is dryly mixed for 2 minutes, add about 5.2 to 5.5 percent of water and continue to add water while stirring. Water that is 80% of the total should be added, and then decide whether to continue to add or not depending on the consistence (noting that the water must be clean water and sewage can not be used). Then it is wetly mixed for 4 minutes and stirred for not less than 6 minutes at one time, until castable is even. In general, the bottom is slightly dry and the wall of the ladle is slightly dilute (the amount of water is only for reference). 4, The amount of water and mixing time should be controlled strictly when stirred to ensure that the needs of the consistency are met. If castable is too thin, it will seriously affect the quality of the material. The stirred volume, stirring time and water that is added should be consistent and they can not suddenly be thick or suddenly be thin. If the consistency does not meet the requirements, the castable should be put back to the mixer and stirred with appropriate water or dry materials. 5, It should be stirred evenly and casting should finish in 20 minutes, in order to avoid sclerosis, affecting structural strength of ladle lining 6, After each completion of construction, varieties of castable should be changed and the mixer should be cleaned 7, Stirring can stop in halfway. If the mixer breaks down and it can be repaired in a short time, some of the materials have to be removed before the machine is opened. If the machine can be repaired on time, castable refractory should all be removed.

- Q: What is high alumina refractory?

- High alumina refractory: High alumina refractory products, with high refractoriness, compressive strength and refractoriness under load, it is used for masonry of a variety of large-scale blast furnaces such as steel furnace, air heating furnace and electric furnace, and for high-temperature parts of thermal equipment like rotary?kilns.

- Q: What is shapeless refractory with high performance?

- The popular ones are: Non-cement fine powder bonded castable is a functional refractory castable with nano material introduced.

- Q: Can polystyrene foam color steel plate be used as decorative fireproofing material ?

- As far as I am concerned, polystyrene foam color steel plate cannot be used as decorative fireproofing material. Because polystyrene flame retardant and non-flame retardant of the points, from the fire retardant is generally self-extinguishing. Polystyrene is the polymer synthesized by styrene?monomer through free radicals polycondensation reaction. It is a transparent thermoplastic?plastic. With above 100 ℃ glass transfering temperature,it is often used to make a variety of disposable container and disposable foam lunch box which have to withstand the boiling water temperature.

Send your message to us

Raw Materials for Refractory:Shaft Kiln Bauxite Al2O3 75-95%

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords