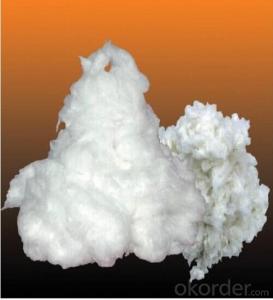

Raw Materials for Refractory:Insulation Ceramic Fiber Bulk

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1)Asbestos free

2)Resistance to high temperature and chemical erosion

3)High mechanical strength

4)Low thermal conductivity

1260 Insulation Ceramic Fiber Bulk for Sale

1)Ceramic fiber bulk is made of coal gangue by melting at high temperature through resistance furnace, before being blown or spun into fiber.

As a neutral and acidic material, except reaction with the strong acid-alkali, ceramic fiber won’t be eroded by other weak alkali, weak acids, or water, oil, steam, or be infiltrated with lead, aluminum or copper, featuring excellent flexibility and elasticity,also lightweight,heat insulation,low thermal conductivity etc.

2)Specifications

1.STD 1260 Ceramic Fiber Bulk

2.HP 1260 Ceramic Fiber Bulk

3.HA 1360 Ceramic Fiber Bulk

4.HZ 1430 Ceramic Fiber Bulk

3)Application:

(1)Raw material for fiber blanket, board products; Raw material for fiber textile products;

(2) Joint sealing and filling insulation for industrial kilns and fuming channel and high temperature pipes

(3) Raw material wet processed products;

(4) Fiber spraying;

(5) Raw material for coatings and castables

(6) Insulation fillings for corner and complex space.

Technical data

ITEM | Standard | Prue | High Aluminum | Zirconium | ||

Classification temperature(℃) | 1260 | 1260 | 1360 | 1430 | ||

Work temperature(℃) | 1050 | 1100 | 1200 | 1350 | ||

Color | white | white | white | white | ||

Fiber Diamond (um) | Blowing | 2-4 | 2-4 | 2-4 | 2-4 | |

| Swinging | 3-5 | 3-5 | 3-5 | 3-5 | |

Chemical Composition(%) | AL2O3 | 46 | 47-49 | 52-55 | 39-40 | |

| AL2O3+ SIO3 | 97 | 99 | 99 | - | |

| AL2O3+ SIO3+ ZrO2 | - | - | - | 99 | |

| ZrO2 | - | - | - | 15-17 | |

| Fe2O3 | <1.0 | 0.2 | 0.2 | 0.2 | |

| Na2O+ K2O | ≤0.5 | 0.2 | 0.2 | 0.2 | |

1)Asbestos free

2)Resistance to high temperature and chemical erosion

3)High mechanical strength

4)Low thermal conductivity

5)Low thermal storage

6)Resistance to heat-shock

7)Easy installation

- Q: How much is the content of boron carbide in refractory material?

- Boron carbide is used in refractory material. For example, generally we could add 0.2% of boron carbide into magnesia carbon bricks. It is suggested that 0.5% is enough, because it has strong effect in boosting melt. It is said that 0.5% would be alright since boron oxide after oxidation belongs to material of low melting point, so the amount should be limited within 0.5%-1%,

- Q: Who can tell me about the foundry refractory materials?

- Such as: neutral, alkalic, acidic refractories. Of course, the raw materials of different materials are not the same. Such as: the magnesia-carbon bricks, basic refractory materials: magnesite(electric?smelting, high-purity)+ crystalline flake graphite+ phenolic resin+ additive (aluminate or silicon powder or silicon carbide powder or high-temperature pitch) and so on.

- Q: What are included in roof thermal insulation fireproofing material?

- Aluminium foil, bubble, aluminium foil/air bubbles/fireproofing aluminium foil thermal insulation material, fireproofing bubble thermal insulation material, fire?retardant thermal insulation material, thermal insulation construction materials, aluminum foil insulation material.

- Q: What effect does aluminium powder play in refractory bricks?

- Aluminum powder is the main temperature resistant material ~ ~ ~ ~!

- Q: I want to know what is the slim in the refractory bricks

- Where are you from, I can introduce to you

- Q: how to divided the external wall thermal insulation materials fire rating

- Level A: Incombustible building material is a material that does not occur any burning. Level A1: Noncombustible means no open fire. Level A2 It is noncombustible, and should measure smoke to be qualified. Level B1: Nonflammable building material: Non-flame material has good flame resistance. It is difficult to fire under the condition of open fire in the air or high temperature, and it is not easy to quickly spread, and when the combustion?source is removed, the combustion will stop immediately. Level B2: Combustible?building?materials: Flame material has a good flame resistance. In case of fire in the air or at high temperature, it will immediately burst into flames, and easily lead to the spread of fire, such as wooden column, timber roof truss, timber beam and wooden stairs. Level B3: inflammable building material has no any flame resisting effects, and is easy to burn, so the fire risk is high.

- Q: How should refractory cement be used?

- Refractory cement is very easy to use. Add some water and mix, and it will harden. Generally there is no need to add other binding agents, but you can add some refractory aggregate and powder. If you use only refractory cement, it will generate a lot of cracks after high temperature. Generally refractory cement can withstand temperature of about 1300 degrees.

- Q: how to classify Insulating Refractory ?

- Insulating Refractory by the physical form of the material is divided into: thermal insulation refractory slab, thermal insulation refractory blanket, thermal insulation refractory loose wool, and thermal insulation refractory irregular part. thermal insulation refractory material can also be classified by materials, temperature, manufacturing technique and application area.

- Q: What are fire resistant level standards of class A fire resistant door?

- Grade standards: class A fire resistant door is an important part of fire-fighting apparatus, and an important step in the social fireproof work. The quality and use of class A fire resistant door is closely related to the success or failure of the fireproof work.. There are steel and wood for class A fire resistant door materials. Only those whose fire endurance is no less than 1.5h can be called class A fire resistant door. In general, the class A fire resistant door internal material is perlite, and still some are vermiculite fireproof board, foam core board, MCcomposite materials, and other fireproofing materials. The thickness of class A fire resistant door is usually 50mm. In places where there is strict requirements for fireproof?performance, class A fire resistant door is often installed.

- Q: Who knows about the B-level fireproof insulation materials?

- Organics, extruded sheet, polyphenyl board and phenolic resin. The fireproof?performance of sea capacity module (fireproof and thermal insulation material) is B1-level with the heat conductivity coefficient of only 0.028w / m · k. It is a good choice. A-level: Rock wool, glass wool, silicate, aluminum silicate, calcium silicate, phenolic aldehyde, and foam glass. B-level: Rubber and plastic, extrusion molding, polyphenyl, PEF.

Send your message to us

Raw Materials for Refractory:Insulation Ceramic Fiber Bulk

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords