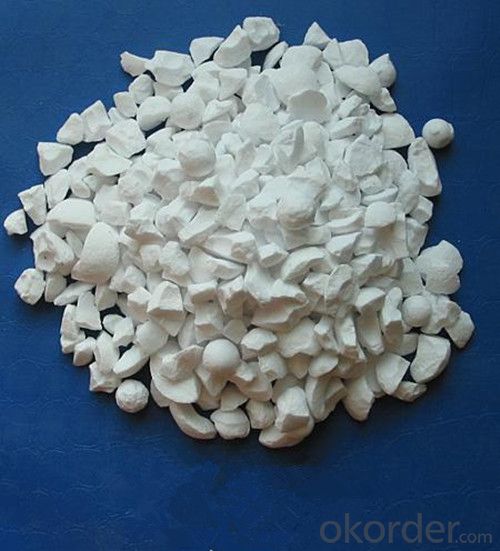

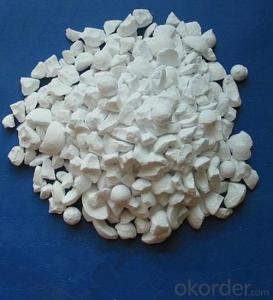

Raw Materials for Refractory:High-Quality Tabular Alumina - Good Price, Delivery Time

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications:

white tabular alumina

1.Al2O3>99.2%

2.Past ISO9001-2008

Description:Tabular Alumina is a pure sintered α-alumina materials that has been fully densified by rapid-sintering without the use of sintering aids at temperature in excess 1900°C.

Tabular Alumina has characteristic large, well developed hexagonal tablet shapedα-alumina crystals of up to 200µm length. applications include its use in electrical insulators, kiln furniture and as a catalyst support.

High refractoriness

Excellent thermomechanical properties

High volume stability

High density, low permeability

High thermal shock resistance

High chemical resistance

High purity

High mechanical stability

High wear-resistance

Series

Sizes, mm (mesh)

Benefit

Coarses

0-0.5mm

0-1mm ,

0-3mm0.2-0.6mm

0.5-1mm

1-2mm

1-3mm

2-5mm

3-6mm

Adds thermal shock and corrosion resistance to refractory products

Fines

0-325

Optimizes the particle size distribution and refractoriness of the refractory matrix

If you’ve kind enquiries, please don’t hesitate to let us know. ^_^

- Q: what kind of refractories is used to make the industrial silicon furnace mouth long life?

- Fused zirconia corundum brick, the smelter of the glassworks is used this kind of lining, and you can contact by private letter.

- Q: hat kind of fire retardant materials are there

- fire-retardant materials include phosphorus chlorine, bromine and antimony, aluminum, boron based flame retardant, nanometer magnesium hydroxide, high purity industrial grade magnesium hydroxide flame retardant, high purity industrial grade modified magnesium hydroxide flame retardant, composite flame retardant magnesium hydroxide, aluminum hydroxide flame retardant, modified aluminum hydroxide flame retardant, light magnesium-oxide, unsaturated resin flame retardant, silicone rubber flame retardant, polyamide flame retardant, PE flame retardant, PP Flame Retardant, PVC flame retardant, wood flame retardant, special flame retardant for paper, CPE flame retardant, fabric coating rubber flame retardant, flame retardant carpet adhesive, water based coating flame retardant, oily coating flame retardant, power coating flame retardant, ink flame retardant, and heat stabilizer.

- Q: How is grade of fire endurance divided?

- Level of the building is classified according to the importance, fireproofing, durable life and etc. different angles. Civil buildings are classified according to the following ways: 1, It is divided into five grads according to its importance: A, AAA level: Buildings with great memorial, of historic, international and national level. B, A level: High-grade residential buildings and public buildings. C, B level: Intermediate residential buildings and public buildings. D, C class: Ordinary residential buildings and public buildings. 2, It can be classified into four types according to the fireproof performance: Fire resistance level of the buildings is divided into four levels. Standard of fire resistance level is decided based on the combustion performance and fire endurance of the main components of the building. 3, It can be classified into four levels according to the durable life: A, A level durable life is more than 100 years. It is applicable for important buildings and high buildings. B, B level has a endurance for 50 to 100 years and it is applicable for ordinary buildings. A, C level has a durable life of 25 to 50 years. It is applicable for less important buildings. B, D level has a lasting year of below 15 years and it is applicable for temporary buildings.

- Q: Which are fireproofing external wall materials?

- For example, Grade-A waterproofing external wall thermal insulation material: glass wool, foam glass, foam cement, hole-closed perlite, rock wool; Grade-B1 waterproofing external wall thermal insulation material: XPS after special treatment. There are also PU after special treatment, phenolic aldehyde and gelatine powder polyphenyl granule. Grade-B2 waterproofing external wall thermal insulation material: PE, and EPS. Grade-A: Completely fireproofing buliding material. Without probility of burning, completely fireproofing buliding material is expensive and unnecessary for home decoration. It is usually used in arsenal and electrical equipment department store. Grade-B1: nonflammable building material: With good flame resistance, nonflammable building material will not burn in the air or at high temperature, but it maby burn in the air and at high temperature. But when the fire source ransfers, it will be out immediately. Grade-B2: combustible building materials. Due to its small firresistance, it is easy to burn in the air or at high temperature, such as wooden building materials. The above are external wall fireproofing material of different classes.

- Q: How long is the duration of fire resistance that fireproof window of level B can endure?

- Fire proof window of level B is the fire proof window whose duration of fire resistance is not less than 1 hour. Technical requirements: One, Materials and fittings (1) the frame of windows draw on steel or wood frames which have certain intensity and are able to ensure the integrity and stability of components. (2) Steel frame and layering can use galvanized steel or stainless steel plate. Its selection criteria shall be in line with provisions 5.1 of GB12955< steel fire door general technical conditions >. (4) The internal fillings of steel, wood frames should use non combustible materials. (5) Fire proof windows can opt for qualified products without affecting the performance of fire proof window. Light transmittance of glass shall not be less than 75% of the same layer of ordinary flat glass. (6)The sealing material between the frame and the fireproof glass should adopt the nonflammable materials, functioning as the fire blocker. (7)Hardware fittings should be tested for qualified products.

- Q: Refractory factory grinding brick dust harmful to the body?

- Therefore, in the workshop work must pay attention to do their own protection.

- Q: The difference between refractory and thermal insulation material

- Refractory refers to inorganic non-metallic material, whose refractoriness is not less than 1,580℃, but refractory is not necessarily insulated material. Inorganic thermal insulated material also belongs to refractory as long as its refractoriness is higher than 1,580℃.

- Q: What are the main characteristics of the sic refractories?

- 1. The usge temperature of silicon carbide refractory is generally 1760 ℃ 2. The silicon carbide refractories can withstand the dramatic changes of temperature and have a good thermal shock resistance performance. To prevent the cracking or breaking of lining refractories. 3. Under the conditions of high or low temperature, it can withstand a certain compressive stress. 4. Under the conditions of high or low temperature, it can withstand friction. 5. It can withstand the huge hydraulic pressure or buoyancy of the metal. 6. It can also withstand the effect of furnace gases to prevent the infiltration of other refractories and reactions.

- Q: Who knows what kind of fire protection material is better?

- Characteristic of polyurethane rigid foam thermal insulation decorative composite board: (1) ultra high cost performance, increased property's selling point (high cost performance) new model of thermal insulation material, excellent thermal insulation properties, elegant decorative effect, 50 years of service life, reduce maintenance costs and social waste. (2) it overcomes defects of traditional insulation technology (to solve the freezing and thawing, veneer cracking and shedding) traditional benzene board, the phenomenon of freezing and thawing that is easily appear in plastic extruded sheet, paint finish is easy to crack; its veneer facing can easily fall off; thermal insulation materials and wall are poorly adhered, easy off the whole. There is a themal bridge in dry hanging wall. (the characteristics of polyurethane composite board)

- Q: How to classify fire resistance rating of brick-concrete structure?

- In order to ensure the safety of the building, the fire protection measures must be taken to make it have a certain degree of fire resistance, even if there is a fire, it will not cause too much damage. According to the national conditions of our country, and in the light of other countries standards, < high-rise civil building fire protection design specification > defines fireproof rank of high-rise civil buildings into level one and two; < code for fire protection design of buildings > divides the rank into level one, two, three, four, level one is the highest level, level four is the lowest. Besides that the minimum fire resistance of the building component is specified, buildings of fire resistance rating also specified requirements for combustion performance. Because the component with the same fire resistance limit is different, it is different in the fire.According to our country national standard < building design fire protection code >, the fire resistance rating of the building is divided into four levels. The fire resistance of a building is determined by the combustion performance and fire resistance of building components (such as beams, columns, floors, walls, etc.). Generally speaking, the fire resistance building of level one is a mixed structure of reinforced concrete structure or a mixture of brick wall and steel concrete structure; the fire resistance building of level two is a mixed structure of steel truss structure, reinforced concrete column and brick wall; the fire resistance building of level three is brick-wood structure made of wood roof and brick wall; the fire resistance building of level four is combustible structure which is composed of wood roof and non-combustible wall.

Send your message to us

Raw Materials for Refractory:High-Quality Tabular Alumina - Good Price, Delivery Time

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords