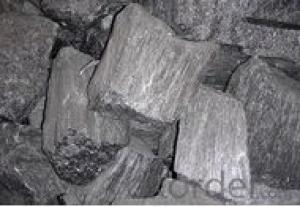

Raw Materials for Refractory - Fused Mullite 70

- Loading Port:

- Tianjin Port or as Customers' Required

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Ton/Tons m.t.

- Supply Capability:

- 10000 Ton/Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of Fused Mullite 70:

Place of Origin:China mainland

Material:Alumina Block

Al2O3 Content(%):70-77%

Shape:Block

Specifications of Fused Mullite 70:

| Chemical/Physical Analysis | WFM70 |

| Al2O3 (%) | 60-70 |

| SiO2 (%) | 25-35 |

| Fe2O3(%)Max | 0.8 |

| TiO2(%)Max | 0.2 |

| Na2O+K2O(%)Max | 0.5 |

| Apparent porosity(%)Max | 5 |

| Bulk density(g/cm3)Min | 2.95 |

| Refractoriness(℃)Min | 1750 |

Packaging & Delivery:

Packaging details:1mt big bag or according to customers’ requirements

Delivery:7-15 work days after the order is confirmed

Fused Mullite Applications:

1.Fused Mullite is widely used as raw materials for high grade refractories ,such as the lining bricks in glass kiln furnace and bricks used in hot wind furnace in steel industry .

2.Fused Mullite's also used in Ceramic kiln and petrochemisty industry and many other applications.

- Q: Can anyone tell me what is A-leve fireproof material?

- What you say is probably palstic! B-level means the fireproof rating is at B1-level because palstic material doesn't belong to fireproof materials. It only is fire?retardant. When wholesaling all kinds of insulation materials and construction, it need tos look at the names. B1-level refers to the fire endurance rating of the fireproof material, which is determined according to the fire resistance of the material. In addition, different parts of the material have different fire endurance ratings! You can download a "Specifications of Fireproof Design for Buildings" for further information!

- Q: what is the grading standards of external wall thermal insulation materials?

- What is the grading standards of external wall thermal insulation materials? summarizing the three versions of GB8624 (1997,2006,2011) external wall insulation fire rating can be basically divided into: A1, A2, B1, B2, B3 and other levels. the dividing is based on many technical indicators. It takes time to explain for It is professional and technical. For details, please contact Qingdao Shan Textile Instrument. they specialized in external wall insulation fire rating tester.

- Q: Technical scheme of refractory for refuse incinerator

- Incinerator conditions and requirements for refractory lining1, working conditions: deal with rare earth, furnace body normal use temperature of 800~900 degrees.2, the specific requirement for refractory: refractory has good resistance to acid corrosion, thermal shock performance good stability and good high temperature.

- Q: How to divide the fire resistant level of EVB?

- 1. The thermal insulation material of level A combustion performance: Inorganic fiber spray coating, glass wool, foam glass, foamed ceramics, rock wool, foam cement and hole-closed perlite, etc. 2. combustion performance is level B1 insulation materials: Extruded polystyrene board (XPS) after special treatment / Special treatment of polyurethane (PU), phenolic aldehyde and gelatine powder polyphenyl granule 3, combustion performance is level B2 insulation material: Molded polystyrene board (EPS), extruded polystyrene board (XPS), polyurethane (PU), polyethylene (PE), etc. I hope I can help you!

- Q: What kinds of refractory will be used in kiln of sintering ceramics?

- High alumina brick, clay brick, insulating brick and silicon carbide plate.

- Q: What refractories are resistant to fluorine gas?

- It is recommended to use fused-quartz brick, which will produce hydrofluoric acid fluorine (an acidic gas) when water vapors. It is cheap. While it is recommended to use silica?brick if it exceeds 1,200 degrees. So acidic refractory is an advisable refractory for using. It works well if the temperature is below 1200 degrees.

- Q: Which fire-resistant materials have good viscidity?

- Viscidity is necessary for gunning mix, repair mix and bordering. It is too broad to which has good viscidity. Both gunning mix and repair mix are powder before adding water. Bordering also has little viscidity before heating. The question shoule be more specific.

- Q: What are the specific steps of stirring the steel ladle castable?

- Steps are as follows. 1 Compulsory mixer is used to stir the castable and bags, rope and other debris can not mix in the castable when stirred. 2, Castable should be unpacked on the scene. Stirred volume depends on the capacity of the mixer. Castable should be accurately measured and put into a blender. 3 The process of first dry mixing and then wet mixing is adopted. After the castable is added to the mixer, it is dryly mixed for 2 minutes, add about 5.2 to 5.5 percent of water and continue to add water while stirring. Water that is 80% of the total should be added, and then decide whether to continue to add or not depending on the consistence (noting that the water must be clean water and sewage can not be used). Then it is wetly mixed for 4 minutes and stirred for not less than 6 minutes at one time, until castable is even. In general, the bottom is slightly dry and the wall of the ladle is slightly dilute (the amount of water is only for reference). 4, The amount of water and mixing time should be controlled strictly when stirred to ensure that the needs of the consistency are met. If castable is too thin, it will seriously affect the quality of the material. The stirred volume, stirring time and water that is added should be consistent and they can not suddenly be thick or suddenly be thin. If the consistency does not meet the requirements, the castable should be put back to the mixer and stirred with appropriate water or dry materials. 5, It should be stirred evenly and casting should finish in 20 minutes, in order to avoid sclerosis, affecting structural strength of ladle lining 6, After each completion of construction, varieties of castable should be changed and the mixer should be cleaned 7, Stirring can stop in halfway. If the mixer breaks down and it can be repaired in a short time, some of the materials have to be removed before the machine is opened. If the machine can be repaired on time, castable refractory should all be removed.

- Q: Does anyone know about the A-level fireproof materials?

- rock wool external wall composite board, A1-level fire rock wool board, hidden slit rock wool board ? 30, A1-level fireproof mineral wool sound-absorbing board. What about the sound-absorbing sheet? glass fiber acoustic board engineering of the TV backdrop ? 85, A1-level fireproofing and thermal insulation rock wool board is hydrophobic thermal insulation, external wall thermal insulation materials ? 200, high temperature resistant calcium silicate board, LCFC/calcium?silicate?board is A1-level fireproof materials with high-quality and low-price ? 75, the prices above are from the internet for reference only, and the purchase prices vary according to the market.

- Q: How many external wall thermal insulation fireproof material are there

- External wall thermal insulation materials are generally divided by the burning grade, into class A, B grade. Grade A is non combustible material, grade B is combustible material. Class A which can be divided into thermal insulation mortar, bakelite plate, rock wool plate, foam cement plate etc.. Insulation mortar is relatively good, easy for construction, convenient, low cost, but its production process is too simple, so it is prone to fake. I recommend you to find a large manufacturing factory that posses complete procedure, for example, provincial production record, the provincial use record, municipal record, tset report at or above the provincial level, state fire proof report, design drawings of office building. product will not be safe if there is a lack of any of these documents. Burning level for henolic is uaually class B, but class A2 can be reached if a thin layer of mortar is applied on the suface,(A1 is the highest level of fire safety),intensity of phenolic is not high, finger pressing will leave a pit on it. if classified according to kilogram, raw material differs greatly every 10 kilogram. Rock wool is also classified by kilogram, general using 150kg wool. Rock wool are now comprounded with average strength. It will easily absorb water, having trouble applying paints. Foam cement strength is not high, easy to absorb water, It is not resistant to falling. It costs low, only used unless little profit can be made, Do not use it if worrying accidents would happen. These materials can be firstly burned, The palce the sample into water to see if it will dufuse at last. External wall should stand up to wind and rain. In terms of thermal insulation, they are almost the same, shows little differences on design thickness.

1. Manufacturer Overview

| Location | Tianjin,China |

| Year Established | 2006 |

| Annual Output Value | Below US$1 Million |

| Main Markets | Mid East;Western Europe;Japan;North America |

| Company Certifications | The Authentication certificate of Quality Management system |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 61% - 70% |

| No.of Employees in Trade Department | 50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 300,00 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | Design Service Offered |

| Product Price Range | Average |

Send your message to us

Raw Materials for Refractory - Fused Mullite 70

- Loading Port:

- Tianjin Port or as Customers' Required

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Ton/Tons m.t.

- Supply Capability:

- 10000 Ton/Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords