Raw Materials for Refractory:Alumina (Al2O3) Aluminum Oxide/Aluminium Oxide

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Purity Aluminum Oxide/Aluminium Oxide

Specification:

1. High purity alumina calcined

2. Hot sale overseas

3. Competitive price

Application:

1. aluminium oxide for aluminium smelting, glass, ceramic industry etc.

2. aluminium oxide for refractory, coating, abrasive applications.

3. aluminium oxide for electric basal plate, desiccating agent, chemical and pharmacy industry, etc.

aluminum oxide property:

It has higher hardness and slight lower toughness comparing with brown fused alumina. It is also characterized by its high purity, ability of self-sharpening, better cutting, less heat emit, higher efficiency, acid and alkali resistance, good thermal stability. As the abrasive materials, it is suitable for grinding high-speed, high carbon steel, as loose grains, it widely used for bonded and coated abrasives , polishing, precision casting and so on .

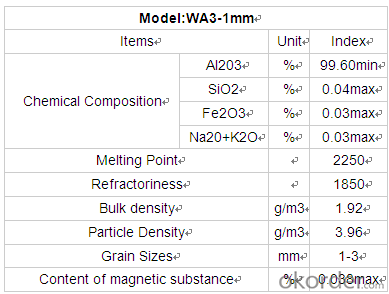

white fused alumina grits&powder chemical composition

aluminum oxide property:

Soluble in water white solid. Odourless. Tasteless. Qualitative very hard. Easy absorption of moisture and not ChaoXie. Both sexes oxide, soluble in inorganic acid and alkaline solution, almost insoluble in water and the polar organic solvents. The relative density (d204) 4.0. Melting point about 2000 °C.

The physical and chemical analysis:

Main standard:

Alumina(industry grade) made by slkali-lime sintered,It is white powdered crystal with low assay of Ti, Mn, Zn, Cu, V, Zr, Cr, Li, Pb, B, P, etc.It is used in the production of fused salt eletrorefining aluminium, corundum eramics, refractories and other alumina chemical products.

Product Pictures:

If you’ve any enquiry please don’t hesitate to contact us!

- Q: what's the seal of fireproofing material?

- Folded organic putty takes organic material as bond,it has certain flexibility or plasticity while using, and it's products are thick liquid or cement shaped object. Folded WXY-II is powered?solid that takes inorganic materials as main components, it has certain workability while used with admixture. Folded fire retardant bag is the packaged object made by fireproofing material, and it's suitable for fireproofing seal of larger openings or fire separation of cable?bridge(fire retardant bag also refers to fireproof bag) Folded fire retardant module is the solid made by fireproofing material with certain shape and size, and it is easy for cutting and drilling, suitable for fireproofing seal of opening and cable?bridge. Folded seal board is made by fireproofing material, it's easy for cutting and drilling, suitable for fireproofing seal of large opening. Folded foam seal is a kind of fireproofing material that can automatically expand and foam and sealed by opening after injecting the foam into opening. Folded sealing strip is a product or flexibility coiled material mede by fireproofing material with certain geometry shape. Folded sealing gum is a kind of liquid fireproofing material that has a function of fireproofing and sealing. Folded fire retardant bag is soft and windable tape-shaped product made by fireproofing material, it is winded on the external surface of plastic pipe and fixed with steel belt or other proper methods, it's the expansion, squeezing and softening pipe after contacting with fire, opening left by burning or soften of seal plastic pipe. Folded fire retardant ring is the product made by fireproofing material and metal shell, it's covered on the external surface of the plastic pipe, expanding and sealing after contacing with open fire, the opening left by burning and soften of plastic pipe when it passes through the opening of wall and floor.

- Q: Can anyone tell me the requirements of the refractory masonry??

- Kaolin is mainly composed of kaolinite crowded minerals that is in the shpe of tiny flake which is less than two microns, tube and folding flake. The kaolinite crowded mineral consists of kaolinite, dickite, pearl stone, halloysite, etc. and its ideal chemical formula is AL2O3-2SiO2-2H2O. The main mineral component of it is kaolinite and halloysite.In addition to the kaolinite crowded mineral, kaolin is accompanied by other minerals like montmorillonite, illite, pyrophyllite, quartz and feldspar. The chemical composition of kaolin contains large amounts of AL2O3, SiO2, and a small amount of Fe2O3, TiO2, and traces of K2O, Na2O, CaO and MgO, etc. The white pottery is made of kaolin. At present, the internationally accepted scientific name for kaolin is Kaolin which is derived from the kaolin mountain in the eastern suburb of kaolin village in Jingdezhen.Such special properties of kaolin as its plasticity,cohesiveness, certain dry strength, sinterability and firing whiteness make it the main raw material for ceramic production; properties like whiteness, softness, high dispersibility, and adsorbability allows it to be widely used the paper industry. In addition, the kaolin is also widely used in some industrial sectors such as rubber, plastics, refractories, oil refining as well as agriculture sector and cutting-edge technology for national defense. According to the purpose and requirements, kaolin can be processed and purified and it can be used to manufacture activated clay.

- Q: How to divide the materials according to the National Fireproofing Material Standard?

- 2,generally, the external wall thermal insulation materials is divided in accordance with fire rating: 1, the class A combustion performance of insulation materials : inorganic fiber spray coating, glass wool, foam glass, foamed ceramics, rock wool, foam cement, hole-closed perlite ect.. 2) class B1 combustion performance of thermal insulation materials: Extruded polystyrene board (XPS) after special treatment / Special treatment of polyurethane (PU), phenolic aldehyde, gelatine powder polyphenyl granule, etc. 3) combustion performance of class B2 insulation material: molding polystyrene board(EPS), extruded polystyrene board (XPS), polyurethane (PU), polyethylene (PE), etc. I hope it will be helpful for you

- Q: How to distinguish the construction fire-proof material rating?

- According to national standard GB8624-97,combustion performance of building materials are divided into the following levels: Class A: Incombustible building material: Material that almost never burn. Class B1: Nonflammable building material: Nonflammable materials have good effect of flame resistance. In case of fire it in the air or at high temperature it is difficult to catch fire and spread, and when the fire source is removed, the combustion can stop immediately. Class B2: Combustible?building?material: Combustible materials have good effect of flame resistance. In case of open fire in the air or at high temperature, it will immediately burst into flames and spread the fire quickly, such as wooden column, timber roof truss, wooden stairs, etc. Class B3: Flammable building material: No flame-retardant effect, highly flammable, high risk of fire. According to national standard, the fire?rating of PVC floor must be class B1.

- Q: I want to consult the fire resistant level standards of external wall thermal insulation materials.

- 1, The building with the height larger than or equal to 100m, should have the A-level combustion performance. 2, The thermal insulation material of the building, with a height larger than or equal 60m and less than 100m, should not be less than the level B2 combustion performance. When using the level B2 insulation material, each level should set horizonal fire barrier zone. 3, The thermal insulation material of the building, with a height larger than or equal to 24m and less than 100m, should not be less than the level B2 combustion performance. When using the level B2 insulation material, each two levels should set horizonal fire barrier zone. 4, The thermal insulation material of the building, with a height less than 24m, should not be less than the level B2 combustion performance. When using the level B2 insulation material, each three levels should set horizonal fire barrier zone. I hope my answer will help you. Thank you!

- Q: what is the original materials of fireproof coating?

- Fire retardant coating is composed of the base materials (that is film forming substance), pigments, ordinary coating additives, fire retardant agent and dispersion medium.

- Q: What's the B grade fireproofing material?

- B1 grade ceiling material: gypsum board, fobrous plasterboard, cement particle board, mineral wool decorative acoustic panels, glass wool decorative acoustic board, perlite decorative acoustic board, flame retardant plywood, flame retardant medium density fiberboard, rock wool decorative sheet, flame retardant wood, aluminum foil composites, flame retardant phenolic laminate, aluminum foil glass fiber reinforced plastic composite material, etc.; B1 grade wall material: gypsum board, fibrous plasterboard, cement particle board, mineral wool board, glass wool board, perlite board, flame retardant plywood and medium density fiberboard, fireproof plastic decorative sheet, nonflammable double-sided particle board, multicolor coating, flame retardant wallpaper and wall cloth, flame retardant simulated granite decorative plates, magnesium oxychloride cement prefabricated wall panels, flame retardant glass fiber reinforced plastic plates, PVC plastic clapboards, high-strength and lightweight composite wallboards, fire-retardant molded wooden composite boards, flame retardant colored artificial boards, nonflammable glass fiber reinforced plastics, etc.

- Q: What kind of foundry ingot refractory materials are there? Please be more detailed.

- This question is a little bit extensive, because there are too much foundry ingot refractory materials.

- Q: What are the components of refractory clay?

- The component of refractory mortar comprises refractory powder, binders and admixtures. Almost all the refractory materials can be used as the powder to formulate refractory mortar. Ordinary refractory mortar is made from refractory chamotte powder, an appropriate amount of plastic clay as binding agent and plasticizer. It has low strength under normal temperature, but the ceramic formed under high temperature has a high strength. Refractory mortar which is formed with bonding material of hydraulicity, gas or thermal hardness is called chemical binding chamotte refractory mortar. It is hradened through chemical reaction before below the temperature of ceramic bonding formation.

- Q: For refractory, why is it necessary to store the first mixing materials for some time under proper moisture and temperature?

- It is mainly to remove gas form chemical reactions in the pug, give full play to plasticity and binding properties of combined, and store unburned?brick whose cememting agent is phosphoric?acid or aluminium?phosphate for some time under proper moisture and temperature. For example, to avoid the formed bricks in the initial stage of drying and firing form cracking due to hydration of calcium oxide. Mixing materials is to store the first mixing materials for some time under proper moisture and temperature in order to improve the evenness and moldability of pud, such as making the distribution of combined clay and water more even. The length of storing chiefly depends on the process requirements and the characteristics of blanks. For the producing pug of high temperature kiln furnitures, the storing time is longer. The function of storing mxing materials varies with different natures of blanks. For honeycomb ceramics, it is to fully digest calcium oxide in blanks. For storing magnesia brick blanks containing much calcium oxide, it should be stored for some time in proper humidity and temperature.

Send your message to us

Raw Materials for Refractory:Alumina (Al2O3) Aluminum Oxide/Aluminium Oxide

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords