Raw Materials for Refractory:77% Rotary/Shaft/Round Kiln Alumina Calcined Bauxite

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

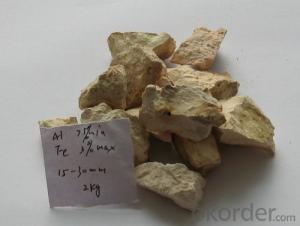

77% Rotary/ Shaft/ Round Kiln Alumina Calcined Bauxite Raw Material for Refractory

Calcined bauxite specification:

Grade | AL2O3 | FE2O3 | TIO2 | K2O+Na2O | CaO+MgO | Bulk density |

75 | 75min | ≤3.0 | ≤4.0 | ≤0.3 | ≤0.5 | ≥2.70 |

80 | 80min | ≤3.0 | ≤4.0 | ≤0.3 | ≤0.5 | ≥2.80 |

85 | 85min | ≤2 | ≤4.0 | ≤0.3 | ≤0.5 | ≥3.00 |

86 | 86min | ≤2 | ≤4.0 | ≤0.3 | ≤0.5 | ≥3.10 |

87 | 87min | ≤2 | ≤4.0 | ≤0.3 | ≤0.5 | ≥3.20 |

88 | 88min | ≤1.8 | ≤4.0 | ≤0.25 | ≤0.5 | ≥3.25 |

90 | 90min | ≤1.8 | ≤4.0 | ≤0.25 | ≤0.5 | |

Calcined bauxite is one of the principal ore of aluminum. Calcined bauxite contains hydrous aluminum oxides and aluminum hydroxides, formed through the laterization of aluminous rocks in tropical and subtropical areas .calcined bauxite is obtained by calcining (heating)superior grade bauxite at high temperature (from 85OC to 1600C) .this removes moisture thereby increasing the alumina content. compared to an alumina content of about 57%to 58%in raw bauxite, calcined bauxite has an alumina content of 84%to88%.the heating is carried out in rotary kilns.

Size:

Lumps /Grains:0-1mm,1-3mm,3-5mm,5-8mm /Powders:100mesh, 200mesh,325mesh

Calcined Bauxite used in

1.aluminium metallurgy,

2 refractory material,

3 precision casting,

4 aluminate cement

Calcined Bauxite Grade:

| 1.Refractory Grade: |

Refractory grade bauxite has high refractoriness, good mechanical strength and moderate slag resistance. Bauxite in the refractory industry is typically used in ladle working lining, tundish furniture, delta sections, general perpose repairment, aluminium melting furnace and mineral processing.

| 3. Rotary calcined bauxite: |

Rotary Kiln Bauxite, as the name suggests, it is the bauxite produced by rotary kiln. there are three kinds of kilns for bauxite production mainly, rotary kiln, shaft kiln and round kiln.

| 4. Shaft kiln calcined bauxite: |

Shaft kiln bauxite, the bauxite calcined by shaft kiln. the raw material-bauxite ore is loaded from the top of kiln together with coal powder and combustion improver,the fire of calcination comes from kiln bottom, about 1300-1400 ℃After the complete calcination, the bauxite is carried out from the bottom.

Packaging & Delivery

Packaging Details: In bulk or in 1-1.25mr bag

Product Pictures:

Our Service:

1. Your inquiry related to our products or prices will be replied in 24hours.

2. Manufacturer with large capacity, ensure the fast production cycle after confirmed the order.

3. Our professional technicians will answer your entire enquiry in patient.

4. To meet the refractory solutions, we can serve as your instructions.

5. Protection of sales area and private information for our entire customer.

If you’ve kind enquiries, please don’t hesitate to let us know. ^_^

- Q: what's the seal of fireproofing material?

- Folded organic putty takes organic material as bond,it has certain flexibility or plasticity while using, and it's products are thick liquid or cement shaped object. Folded WXY-II is powered?solid that takes inorganic materials as main components, it has certain workability while used with admixture. Folded fire retardant bag is the packaged object made by fireproofing material, and it's suitable for fireproofing seal of larger openings or fire separation of cable?bridge(fire retardant bag also refers to fireproof bag) Folded fire retardant module is the solid made by fireproofing material with certain shape and size, and it is easy for cutting and drilling, suitable for fireproofing seal of opening and cable?bridge. Folded seal board is made by fireproofing material, it's easy for cutting and drilling, suitable for fireproofing seal of large opening. Folded foam seal is a kind of fireproofing material that can automatically expand and foam and sealed by opening after injecting the foam into opening. Folded sealing strip is a product or flexibility coiled material mede by fireproofing material with certain geometry shape. Folded sealing gum is a kind of liquid fireproofing material that has a function of fireproofing and sealing. Folded fire retardant bag is soft and windable tape-shaped product made by fireproofing material, it is winded on the external surface of plastic pipe and fixed with steel belt or other proper methods, it's the expansion, squeezing and softening pipe after contacting with fire, opening left by burning or soften of seal plastic pipe. Folded fire retardant ring is the product made by fireproofing material and metal shell, it's covered on the external surface of the plastic pipe, expanding and sealing after contacing with open fire, the opening left by burning and soften of plastic pipe when it passes through the opening of wall and floor.

- Q: what's the standard of fireproofing material?

- first, the classification of fire resistant levels of buildings, 1, the classification basis of fire resistant levels of buildings, the classification of fire resistant levels of buildings is one of the basic building fire protection technology measures, our national architectural design specification divides fire resistant levels of buildings into first, second, third and fourth class, first class ios the highest and has the most strong fire-resistant capacity, fourth class is the lowest and has the weakest fire-resistant capacity. Fire resistant level of buildings depends on the combustion performance and fire endurance of the components of the buildings. construction components refer to the wall, base, beam, column, floor, stair, suspended ceiling and other basic components of buildings. Combustion performance and fire endurance of building components are shown in table 4-11), the combustion performance of building components are divided into non-combustible component,hard-comnustible component,combustible?component,according to their response to the fire. as for building components, non-combustible component includes wall column and base,etc; hard-comnustible component includes hanging?bracket, suspended ceiling and internal pipe;combustible?component includes doors and windows, suspended ceiling, decoration materials,etc.

- Q: What does fire-resistant insulation coating have?

- Refractory thermal insulation material mainly refers to the inorganic thermal insulation material and composite thermal insulation material. According to the shape, it can be divided into: Finishing of fibrous shape, mineral?cotton, rock wool, glass wool, aluminum?silicate?wool, ceramic fiber, etc. Diatomaceous earth of microporous pile, calcium silicate, expanded perlite,expanded vermiculite,aerated concrete, etc. Foam glass of bubble shape, volcanic ash glass, foamed clay, foamed?concrete, gelatine powder polyphenyl granule heat insulating slurry of pasty form, etc. Their common feature is fire-retardant and firproof. It can be used in buildings with high requirements of fire?rating. Calcium silicate, aluminum silicate and asbestos can also be used for piping insulation of heat transport with high temperature.

- Q: What are the basic requirements of continuous casting for molten steel? What are the requirements for refractory materials?

- Refractories for continuous casting is an important part of the continuous casting machine, in addition to the characteristics of general refractory material, also for the purification of molten steel and improve the steel quality, stable molten steel temperature and composition, control and regulate the flow of the molten steel and other functions, so it is called functional refractories. The above is provided by the China Technology Department

- Q: Is there any difference between insulating bricks and refractory bricks? Are there any professional refractories factories that are reliable in the quality and quality of these irritated materials?

- Physical and chemical property indexes of high strength and high alumina refractory bricksProject indexPLG-1.0 PLG-0.8 PLG-0.5 PLG-0.4AI2O3% 56545250Fe2O3%, 2, 2, 1.5, 1.5Bulk density g/cm3 1, 0.8, 0.5, 0.4Normal temperature compressive strength MPa shall be no less than 7531.5A change of a burn line of not greater than 2%The temperature is 1400140012501250 centigradeThe coefficient of thermal conductivity, W/m.k average temperature (350 + 5) is not greater than 0.45, 0.35, 0.25, 0.20

- Q: What are the refractory materials above 1000℃

- It is a piece of cake to meet your requirement, anyway you can try unshaped castables like corundum and other refractory materials used in steelmaking which are above 1500℃ basically .

- Q: Refractory materials are needed for casting metallurgy.

- Refractory material used in foundry work is that refractories for cupola furnace? Cupola is a high temperature furnace which is used for melting molten iron, and refractory material adopted is mainly low iron high grade clay brick and clay lightweight insulation bricks, etc.foundry ingot refractory material is pearl sand (also known as pearl jewelry sand, fused ceramic, ceramic sand) it is made of high quality bauxite material by arc melting furnace.

- Q: How long is the duration of fire resistance that fireproof door of level B can endure?

- The national standard for fireproof door of level B is 1.5h, which must be achieved. The data GB12955-2008 means that the door leaf of raw material is 0.8mm-1.2mm in thickness and door frame is 1.2mm-1.5mm in thickness. And other metal melting temperature shall not be less than 950℃, the duration of fire resistance shall not be less than 0.9 hours. Fire department will check and accept based on the manufacturer's inspection report, so you have to refer to manufacturer's inspection report if you want to know more in detail.

- Q: Manganese steel belongs to refractories

- Material wear and other harsh working conditions, extrusion, there will be work-hardening phenomenon rapidly on the surface. The most important feature of manganese steel is that it is not refractory under a strong impact, and under extrusion conditions, part of it will be fractured. The main form of damage is wear and consumption: It is a kind of inorganic non-metallic material whose refractoriness is not lower than 1580 ℃, mainly used to endure impact. Manganese steel is a kind of high strength steel, which is free of deformation, so that it can remain austenite good toughness and ductility at heart while keeping good wear resistance at the same time on hardened layer. Refractories are

- Q: what's the detailed address of fireproof and thermal inuslation matertial market?

- following are the detailed address of fireproof and thermal inuslation matertial market: Central China Building decoration materials market,Hanxi 1 road No 95, Xinyongan Tangcai decoration material makert, Jianghan district Tangcai road No 53, Baoye decoration material wholesale market, Wuhan Wuchang district Minzhu road No 620.

Send your message to us

Raw Materials for Refractory:77% Rotary/Shaft/Round Kiln Alumina Calcined Bauxite

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords