Raw Materials for Refractory:79% Rotary/Shaft/Round Kiln Alumina Calcined Bauxite

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

79% Rotary/ Shaft/ Round Kiln Alumina Calcined Bauxite Raw Material for Refractory

Specification:

shaft kiln calcined bauxite:

Al2O3:84.0% MIN Fe2O3:2.%MAX TiO2:4.0% MAX Cao+MgO:0.4% MAX K2O+Na2O:0.25%MAX

Bulk Density:2.9 g/cm3 MIN MOISTURE:4.0%MAX

SIZE:0-1MM 1-3MM 3-5MM 0-5MM 5-8MM 0-50MM

100 MESH 120 MESH 150 MESH 200 MESH 325 MESH

Price:

0-50mm USD 270/MT FOB Tianjin

0-1mm 1-3mm 3-5mm 0-5mm 5-8mm USD 305/MT FOB Tianjin

200 mesh USD323/MT FOB Tianjin

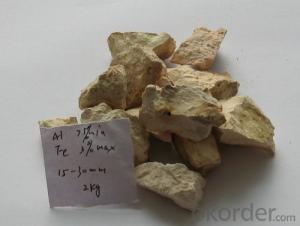

Size of 79% Rotary/ Shaft/ Round Kiln Alumina Calcined Bauxite Raw Material for Refractory::

Lumps /Grains:0-1mm,1-3mm,3-5mm,5-8mm /Powders:100mesh, 200mesh,325mesh

Calcined Bauxite Grade:

1.Refractory Grade: |

Refractory grade bauxite has high refractoriness, good mechanical strength and moderate slag resistance. Bauxite in the refractory industry is typically used in ladle working lining, tundish furniture, delta sections, general perpose repairment, aluminium melting furnace and mineral processing.

3. Rotary calcined bauxite: |

Rotary Kiln Bauxite, as the name suggests, it is the bauxite produced by rotary kiln. there are three kinds of kilns for bauxite production mainly, rotary kiln, shaft kiln and round kiln.

4. Shaft kiln calcined bauxite: |

Shaft kiln bauxite, the bauxite calcined by shaft kiln. the raw material-bauxite ore is loaded from the top of kiln together with coal powder and combustion improver,the fire of calcination comes from kiln bottom, about 1300-1400 ℃After the complete calcination, the bauxite is carried out from the bottom.

Packaging & Delivery

Packaging Details: In bulk or in 1-1.25mr bag

Product Pictures:

Our Service:

1. Your inquiry related to our products or prices will be replied in 24hours.

2. Manufacturer with large capacity, ensure the fast production cycle after confirmed the order.

3. Our professional technicians will answer your entire enquiry in patient.

4. To meet the refractory solutions, we can serve as your instructions.

5. Protection of sales area and private information for our entire customer.

If you’ve kind enquiries, please don’t hesitate to let us know. ^_^

- Q: What are the fire endurance requirements of class A fire resistant door ?

- Hardwares are professional fire resistant lock, fireproof?door closer, fire hinge, handle, latch and sequencer, and they can also be configured according to user needs. Fire resistant time of class A and B fire resitant door is 12h and 09h respectively. It can also be customized according to customer needs into a variety of non-standard specifications. Steel fire door is developed in accordance with the national standard GB12955-2008, and in line with ISO3008, BS476 standards. Requirement: fire endurance should meet the A,B and C fireproof requirements respectively. You can also choose to install hold-open door device to leep the door leaf usually in open. Doorframe and door leaf is made up of imported or domestic quality electrolytic steel plate, electro galvanized steel plate or stainless?steel plate, filled with quality expanded perlite fireproof?panel which can withstand high temperature above 1200 ℃. The surface is processd with electrostatic spraying plastics, and auxiliaries are stainless steel fire resistant lock (or pipe shaft lock ) , galvanization for steel (or stainless?steel) fire hinge, domestic(or imported) door?closer.

- Q: For refractory, what is critical particle size? Thank you.

- Critical granularity means the maximum size of particles in refractory.

- Q: Which brand of thermal insulating refractory is good?

- Brands of thermal insulating refractory: 1, Armaflex(German brand). Manufacturer: Armacell thermal insulation materials (Guangzhou) Co., Ltd, Armacell thermal insulation materials (Suzhou) Co., Ltd. 2, Durkflex (American brand) Manufacturer: Durkee (Guangzhou) thermal?insulation?material Co., Ltd. Durkee (Wuhan) thermal?insulation?material Co., Ltd. 3, Aeroflex (Thailand Brand) Manufacturer: Aeroflex Polymer Technology (Shanghai) Co., Ltd.

- Q: I know which material is the fire resistance rolling shutter door

- Fire resistance rolling shutter door and ordinary roller shutter are basically same, the differences are: Its inner and outer sides are generally made of galvanized iron sheet, filling asbestos fireproofing material betwwen two layers of fire resistance rolling shutter door, and some fire shutter doors can be interlocked with the relevant fire control system, when the breaking out of fire , it can automatically "half-drop" and "full drop".

- Q: what are the requirements of fireproofing material?

- answer: 1 fireproof materials are used in construction, in various forms and it has played an absolute role in modern fireproofing, common fireproofing materials include fireproof?panel, fire door, fireproofing glass, fire?retardant?coating, fireproof bag,etc. 2, fireproof?panel is the most common texture in the market. There are two common types: One is the high pressure decorating refractory slab, it's advantages are fireproofing,moisture-proof, wear-resistant, oil resistant, easy to clean, and it has various colors; another one is glass magnesium fireproof board, external layer is decoration materials, and inner layer is mineral magnesium fireproofing material, and it can endure 1500 degrees high temperature but has bad decoration. Installing fireproof suspended?ceiling in outlet channel of construction, stairwell and corridor can ensure safe evacuation of people and protect people from attacking of fire spreading in the disaster. 3, the production process of fire and moth proof wood: firstly, put general wooden materials into solution with calcium, aluminum and other cations, then soak it into solution with phosphate radical, silicate and other anions. Thus, the two ions will be carried out chemical reaction in the wood, forming a ceramic-like material, and intimately fill the voids of cells, so that the wood has the fireproofing and mothproof properties.

- Q: What defect does fused cast refractories have ?

- The impact on the quality of glass is mainly the defects that eroded down refractory materials mixed in the glass, thus being prodeced of grass products. Defects are mainly foreign body defects such as sand, knot and wave reinforcement.

- Q: What's the material of electrical fire prevention board?

- Electrical fire prevention board uses the material of inorganic binders, which mainly includes water glass, gypsum, phosphate, and cement; refractory mineral fillers: alumina, asbestos powder, calcium carbonate, perlite, cornstarch and etc.; electrical fire prevention board is mainly aimed at fire protection and thermal insulation. Iron plate is electrically conductive with good thermal conductivity, which will cause the result that the equipment is not insulated and suffers larger superheating surface. Hope my answer is helpful for you.

- Q: What 's the highest temperature can magnesium plate glass resist ?

- Glass magnesium plate is non combustible plate having good fire-resisitance quality. Flame will never burn continuously on it. It does not catch on fire when temperature reach 800 ℃, and will not be lit up at 1200 ℃. The plate, having high-quality keel partition system, is rated as the highest non-combustible level A1 with fire resistance being above 3 hours. It absorbs a lot of heat when fire is burning, delaying rise of ambient temperature.

- Q: Can anyone tell me what is a high alumina refractory?

- Refractories refer to a class of inorganic non-metallic materials whose refractoriness are no less than 1580 ℃. Refractoriness is the Celsius temperature when cone-shaped samples can resist high temperature without softening and melting down in the absence of a load. But it is not accurate to define refractory merely by judging that whether the refractoriness is no less than 1580 ℃. Currently, the materials whose physical and chemical properties allow them to be used in high temperature environments are called refractories. Refractory materials are widely used in metallurgy, chemical industry, petroleum, machinery manufacturing, power and so on, among which the metallurgical industry is the largest demander in this regard, accounting for 50% to 60% of total output. Hope it will help you out!

Send your message to us

Raw Materials for Refractory:79% Rotary/Shaft/Round Kiln Alumina Calcined Bauxite

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords