Raw Materials for Refractory:70% / 75% Alumina 120 Mesh Calcined Bauxite with Low Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

70% Alumina 120 Mesh Calcined Bauxite with Low Price

Specifications

1. We directly supply calcined bauxite

2. Al2O3:70%/75%/80%/85%/86%/88%/90%

3. Size:0-1-3-5-8-10/200mesh/325mesh/400mesh/500mesh

Size:

Lumps /Grains:0-1mm,1-3mm,3-5mm,5-8mm /Powders:100mesh, 200mesh,325mesh

Product Description:

Bauxite, alumina or bauxite miner , main ingredients are aluminum oxide, hydrate alumina containing impurities,

is an earthy mineral.White or grey, brown yellow or light red by iron.From 4 to 3.9 g/cm3 density, hardness, 1 ~ 3, opaque, very brittle.

Very difficult to melt.Insoluble in water, soluble in sulfuric acid, sodium hydroxide solution.Mainly used for aluminium, refractory material.

Calcined Bauxite Grade:

Shaft Kiln Bauxite

Rotarty Kiln Bauxite

Round Kiln Bauxite

Packaging & Delivery

Packaging Details: In bulk or in 1-1.25mr bag

Usage

(1) aluminium industry. Used in national defense, aerospace, automotive, electronics, chemical industry,

daily necessities, etc.

2 precision casting. Alumina clinker made after the mould precision casting processed into fine powder.

Used in military industry, aerospace, communications, instrumentation, machinery and medical equipment department.

(3) is used for refractory products. High bauxite clinker refractoriness is as high as 1780, chemical stability strong,

and good physical properties.

(4) aluminum silicate refractory fiber. With light weight, high temperature resistance, good thermal stability,

low thermal conductivity, heat capacity is small and the advantages of resistance to mechanical shock.

Used in iron and steel, nonferrous metallurgy, electronics, petroleum, chemical, aerospace, atomic energy,

defense and other industries.

(5) in magnesia and bauxite clinker as raw materials, add the appropriate binder,

used for pouring ladle whole ladle lining has particularly good effects.

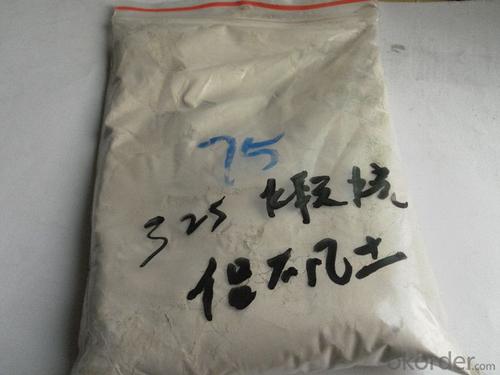

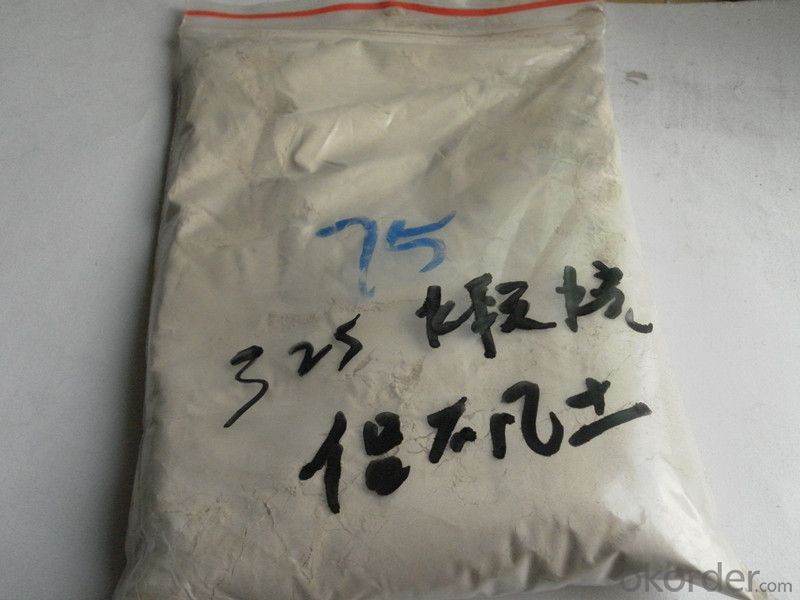

Product Pictures:

Our Service:

1. Your inquiry related to our products or prices will be replied in 24hours.

2. Manufacturer with large capacity, ensure the fast production cycle after confirmed the order.

3. Our professional technicians will answer your entire enquiry in patient.

4. To meet the refractory solutions, we can serve as your instructions.

5. Protection of sales area and private information for our entire customer.

If you’ve kind enquiries, please don’t hesitate to let us know. ^_^

- Q: What are the fire protection standards of insulation materials?

- This question is, like this. The combustion performance of thermal insulation materials for exterior walls of all civil buildings, within the scope of fire design auditing and fire control acceptance, should be brought into the auditing and acceptance. As for the "Management Regulations on Supervisions of Fire Prevention and Control for Building Projects" (Ministry of Public Order No. 106) , all civil buildings which are out of the scope of Article 13 and 14 are included in the random check. Before the release of new standard, it must be strictly implemented the Article II of the "Fire prevention Interim Provisions on civil external wall insulation system and external wall decorative" ([2009] No. 46), namely, the insulation materials of civil buildings must use materials with A-level combustion performance.

- Q: How long is the fire-fighting time of A class fire resisting window?

- Duration of fire resistance of fire resisting window: A class window is not less than 1.2 hours; B class window is not less than 0.9 hours and C class window is not less than 0.6 hours. Technical Requirements: 1materials and accessories (1) window frame structure adopts stell framework and wooden framework that have a certain strength to ensure integrity and stability. (2) steel framework and batten can choose galvanized steel plate or stainless steel The selection criteria meet requirements of GB12955 steel fire door general technical conditions in the provisions of article 5.1. The selection criteria of wooden framework and batten meet requirements of GB14101 wooden fire door general technical conditions in the provisions of article 5.1.1. Filling material of steel and wooden framework shouldn't adopt non-combustibility material. (5) fire-fighting glass can adopt testing-qualified product that don't influence fire resistance performance of fire resisting window. Light transmittance of glass is not less than 75% of the same layer common plate glass. (6) Sealing material between framework and fire-fighting glass should adopt Flame retardant material which can serve as fire-fighting and smoke-resistant when encounter fire disaster. (7) hardware fitting should accessories product that is tested to be qualified. 二. installation requirement: 1. When Party A takes over goods, he should check numbers, specification, grades and whether Accessories are Conformed and complete according to contract.

- Q: What are the requirements of refractory temperature of refractory brick?

- Refractory brick, called refractory?brick for short, is refractory material made by firing refractory clay or other refractory raw materials. Faint?yellow or brownish, it is mainly used in building smelting furnace. It can resist 1,580 ℃ -1,770 ℃ high temperature.

- Q: Who knows the classifications of magnesia refractory?

- Magnesia chrome series products: The main ingredients of magnesium chromium series are MgO and Cr2O3. Periclase is the first phase and magnesia-chrome spinel is the second phase. Products belonging to this series are magnesium chrome brick and chrome magnesia brick. The main ingredients of magnesium aluminum series are MgO and Al203. As they generate MgO and Al203, all magnesium chromium series products contain magnesia material. magnesium calcium series products The main components are MgO and CaO. They have high melting points, which are important magnesia materials. 5, magnesium silicon series products: The main component of magnesite series is SiO2, when the C / S<5, SiO2 and MgO generate MgO.Al2O3 (forsterite). From the perspective of microscopic mineral, main products of pure aluminum series include magnesium aluminum brick, periclase spinel brick, corundum spinel brick and aluminum-spinel castable in unshaped materials. I hope this answer can help you.

- Q: Where is refractory used? Thank you!

- According to its refractoriness, it can be divided into ordinary refractory (1,580℃ to 1,770℃), high class refractory (1,770℃ to 2,000) and super refractory (above 2,000℃); according to chemical property, it can be divided into acid , neutral and alkali refractories, and including refractory used for special occasion. The current definition of refractory do not only depend on whether the refractoriness is above 1,580℃. At present, refractory is widely used as inorganic nonmetallic material of production equipment lining in metallurgy, petrifaction, cement, ceramics, power, etc. Refractory generally has good thermal shock resistance, chemical attack resistance, low thermal conductivity and coefficient of expansion, widely used in chemical, construction material, mechanical manufacturing, and ceramics, accounting for 50% to 60% in the total output. It can resist high-temperature action. Refractory has many varieties. Refractory materials are widely used in metallurgy; chemical properties divided by acidic refractories. In addition, cement, silicates. Refractoriness refers to that when cones sample made from refractory has no load. Currently, refractory refers to that is widely used in metallurgy, including neutral refractory and basic refractory.

- Q: What is refractory aggregate?

- It includes two categories: coarse aggregate and fine aggregate.

- Q: what is the material of fixed first rate fire resistant window?

- Fixed first rate fire resistant window is produced by the steel sash windows, steel casement, fireproofing glass. Fireproof windows, is composed by steel window frame, steel casement, fire-proofing glass. it refers to the window which can isolate and stop the fire spreading. The fire window product is named after the main material of window frame and the window casement, window frames is made of steel, casement is made of wood or the sash frame is made of wood and the casement is made of fire window.

- Q: What are the requirements when producing fireproof materials by kaolin?

- . Kaolin are kaolinite crowded mineral composed of tiny flakes tubulose, lamellar smaller than 2 microns. it is composed of kaolinite, dickite, pearl stone, halloysite etc. I chemical formula of which is AL2O3-2SiO2-2H2O, the main mineral component is kaolinite and halloysite. Except kaolinite and halloysite there are other minerals montmorillonite, illite, pyrophyllite, quartz and feldspar associated. kaolin contains large amounts of the chemical composition AL2O3, SiO2, and a small amount of Fe2O3, TiO2, and small amounts of K2O, Na2O, CaO and MgO, etc. white pottery is made of kaolin and is now internationally accepted scientific name --Kaolin, derived from the eastern suburb of Jingdezhen high-Village side of the mountain kaolinite. kaolin plasticity, cohesiveness, certain dry strength, sinterability and whiteness after burning, making it the main raw material for ceramic production;. white, soft, highly dispersed, adsorption and chemical resistance with other excellent process performance, it has been widely used in the paper industry as well as industrial sectors such as agriculture and defense cutting-edge technology in the field of rubber, plastics, refractories, petroleum refining . according to the purpose and need, it can be processed, treated and purified, they can be used to produce activated clay.

- Q: For refractory, why is it necessary to store the first mixing materials for some time under proper moisture and temperature?

- It is mainly to remove gas form chemical reactions in the pug, give full play to plasticity and binding properties of combined, and store unburned?brick whose cememting agent is phosphoric?acid or aluminium?phosphate for some time under proper moisture and temperature. For example, to avoid the formed bricks in the initial stage of drying and firing form cracking due to hydration of calcium oxide. Mixing materials is to store the first mixing materials for some time under proper moisture and temperature in order to improve the evenness and moldability of pud, such as making the distribution of combined clay and water more even. The length of storing chiefly depends on the process requirements and the characteristics of blanks. For the producing pug of high temperature kiln furnitures, the storing time is longer. The function of storing mxing materials varies with different natures of blanks. For honeycomb ceramics, it is to fully digest calcium oxide in blanks. For storing magnesia brick blanks containing much calcium oxide, it should be stored for some time in proper humidity and temperature.

Send your message to us

Raw Materials for Refractory:70% / 75% Alumina 120 Mesh Calcined Bauxite with Low Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords