Raw Materials for Refractory:80% Alumina 120 Mesh Calcined Bauxite with Low Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

80% Alumina 120 Mesh Calcined Bauxite with Low Price

Specifications

1. We directly supply calcined bauxite

2. Al2O3:70%/75%/80%/85%/86%/88%/90% content

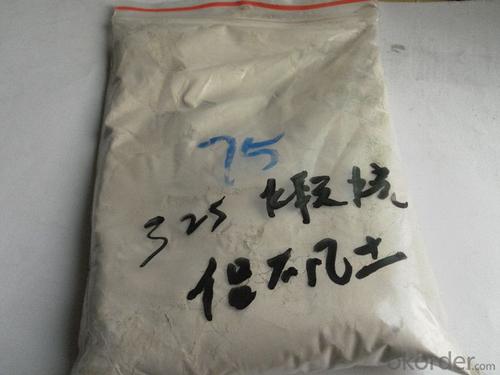

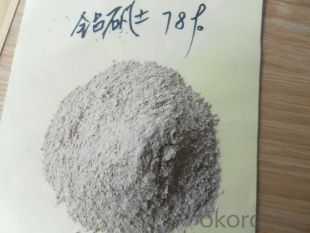

3. Size:0-1-3-5-8-10mm/200mesh/325mesh/400mesh/500mesh

Size of Bauxite 80%:

Lumps /Grains:0-1mm,1-3mm,3-5mm,5-8mm /Powders:100mesh, 200mesh,325mesh

| Item name | RKB-85 | RKB-86 | RKB-87 | RKB-88 | RKB-90 |

| Al2O3 % min | 85 | 86 | 87 | 88 | 90 |

| Fe2O3 % max | 2.0 | 1.8 | 1.8 | 1.8 | 1.6 |

| TiO2% (max) | 4.0 | 3.8 | 3.8 | 3.8 | 3.8 |

| CaO+MgO % (max) | 0.3 | 0.25 | 0.25 | 0.25 | 0.25 |

| K2O+ Na2O % (max) | 0.5 | 0.45 | 0.45 | 0.45 | 0.45 |

| Bulk density(gm/cc) (min) | 3.10 | 3.15 | 3.25 | 3.30 | 3.40 |

| Moisture (max) | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 |

| SiO2% (max) | 9.0 | 8.0 | 7.0 | 6.0 | 4.0 |

| Shipment | Jumbo | Jumbo | Jumbo | Jumbo | Jumbo |

| Package | By sea | By sea | By sea | By sea | By sea |

Product Description of Bauxite 80%:

Bauxite, alumina or bauxite miner , main ingredients are aluminum oxide, hydrate alumina containing impurities,

is an earthy mineral.White or grey, brown yellow or light red by iron.From 4 to 3.9 g/cm3 density, hardness, 1 ~ 3, opaque, very brittle.

Very difficult to melt.Insoluble in water, soluble in sulfuric acid, sodium hydroxide solution.Mainly used for aluminium, refractory material.

Calcined Bauxite Grade:

Shaft Kiln Bauxite

Rotarty Kiln Bauxite

Round Kiln Bauxite

Packaging & Delivery of Bauxite 80%:

Packaging Details: In bulk or in 1-1.25mt bag

Product Pictures:

Our Service:

1. Your inquiry related to our products or prices will be replied in 24hours.

2. Manufacturer with large capacity, ensure the fast production cycle after confirmed the order.

3. Our professional technicians will answer your entire enquiry in patient.

4. To meet the refractory solutions, we can serve as your instructions.

5. Protection of sales area and private information for our entire customer.

If you’ve kind enquiries, please don’t hesitate to let us know. ^_^

- Q: Development trend of refractories

- The foundation of China's refractories industry is still relatively weak, the utilization level of refractory material resources is low, the quality of refractory materials is not high, excess production capacity of ordinary products, the key products of some high-quality high technology content can be produced, but the quality is not stable, and the service life of refractory material consumption compared with foreign advanced level, there is a considerable gap. Therefore, the new trend of tracking foreign refractories science and technology development, carry out and supporting the development and application of advanced and basic theory research, to promote technological innovation of refractory materials, optimizing product structure, industrial structure adjustment, implementation of the strategy of sustainable development, it is very necessary.

- Q: What are the refractory materials above 1000℃

- It is a piece of cake to meet your requirement, anyway you can try unshaped castables like corundum and other refractory materials used in steelmaking which are above 1500℃ basically .

- Q: What's the organzational structure of refractory material?

- Although hacing same chemical composition refractory material products also is mineral organizer. There are differences in the type of mineral phase, high refractoriness under load, quantity and crystalline state. The organizing minerals and microstructure are reflected by folding strength, high temperature pit definite density torsional strength, high-temperature torsional strength and product property. But, for example, wear or crack may cause damage. The performance index can reflect the internal structure of refractory: the nature of the thermal performance---linear expansion coeffcient. And the mineral composition of refractory material depends on the chemical composition and process conditions, the heat capacity and temperature conductivity. If the processing conditions are different, the influence of chemical action, and thermal conductivity: represents the nature of the mechanical properties - normal temperature, high temperature compression strength, high temperature creep performance and elastic modulus. Chemical compositions are the basic characteristics of refractory, representing the nature of the density---porosity, corrosion occurred refractory materials in high temperature use As a result, the composition and quantity directly determines the performance of refractory, true density: representing the forming of high temperature performance --- refractoriness, high temperature volume stability, so you can't analyze the effect on the product performance just from chemical composition. The performance of various refractory materials are different. It must be emphasized that macroscopic organization structure of refractory material is also an important factor that affects performance; reflecting complexity of penetration---air permeability, thermal shock resistance and slag resistance. The main component is the foundation of refractory characteristics.

- Q: How to make use of waste refractory materials whose main elements are alumina and mullite?

- Crushing and pressing refractory bricks, or refractory parts . Such as welding positioner tracks use disposable tools.

- Q: Can I use ordinary cement with the addition of sand, clay, and salt as refractory material to paste the stove?

- You can add some animal hair, like bristles. After all, we don’t have so much hair. Remember not to use cement, because it will crack. Instead, make use of animal hair, lime, yellow mud and sand, after mixing up, and they would be firmer while in calcination.

- Q: Which one is better, fire-resistant wood or steel?

- From the aspect of low-carbon and environment protection, the steel and timber structures are both OK, they are both renewable resources, the steel can be recycled and melt down again and wood can continue to be planted. Fireproof board Fireproof board is a refractory material used for surface decoration. It is widely used in interior decoration, furniture, kitchen cabinets, laboratory tables, walls, and other fields.

- Q: What are fire?ratings of wall thermal insulation material?

- 1.thermal insulation material with grade A combustion performance: YT inorganic active insulation material for wall thermal,rock wool, glass wool, foam glass, foamed ceramics, foam cement, hole-closed perlite, etc. 2.thermal insulation material with grade B combustion performance: Extruded polystyrene board(XPS)after special treatment/polyurethane(PU) after special treatment, phenolic aldehyde,gelatine powder polyphenyl granule, etc. 3.thermal insulation material with grade B2 combustion performance: Molding polystyrene board(EPS), extruded polystyrene board(XPS), polyurethane(PU), polyethylene(PE), etc.

- Q: What crusher is used for raw material of broken refractory material? What is the rough crushing process? What are the materials? Thank you!

- Now cone crusher is generally used.

- Q: what's the detailed address of fireproof and thermal inuslation matertial market?

- Detailed address of fire insulation materials market is as follows: A: Guangzhou Huatai building materials co., LTD. Address: Guangzhou Tianhe Chepo Road no. 10 B: Address of Donglong building materials market: Guangzhou Tianhe Taian North Road no. 7 C: Address of Huiya building materials trade market : Guangzhou Tianhe Sports West Road No. 109

- Q: What is refractory?

- Refractory materials are widely used in metallurgy, machinery manufacturing, chemical industry, petroleum, power and other industrial fields. It is an inorganic nonmetallic material mostly used in metallurgical industry with the minimum refractoriness of 1580 ℃, able to resist high temperature without softening (annealing). It accounts for 50% to 60% in total output. Refractoriness refers to refractory's ability to resist fire.

Send your message to us

Raw Materials for Refractory:80% Alumina 120 Mesh Calcined Bauxite with Low Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords