Quality of Tin Free Steel TFS

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

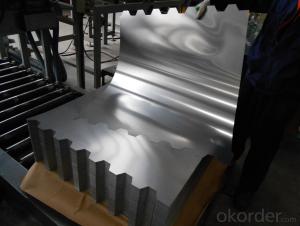

Tin Free Steel (TFS)

Is also known as chromed steel, as it is obtained by coating the metal base (low-carbon steel) with an ultra-thin layer of metallic chrome and then with a chromium oxide layer.This steel product was developed to meet economic requirements, and excels tinplate in paintability, paint adhesion, and economy. It is widely used for making beverage cans and 18-liter cans. It is also used for making photographic film cases and as a protective material for optical fiber cables.

Our TFS Specification:

Standard: AISI, ASTM, BS, DIN, GB, JIS

Material: MR,SPCC

Thickness:0.15mm - 0.45mm

Width: 600mm -1150mm

Temper: T1-T5

Annealing: BA & CA

Coil Inner Diameter: 508mm

Weight: 6-10 tons/coil 1~1.7 tons/sheets bundle

Oil: DOS

Surface: Finish,bright,stone,matte,silver

Packing:

1、For sheets: plastic or waterproof paper, metallic cover and angles, steel strips,wooden pallet.

2、For Coils: plastic or waterproof paper,plastic protect plate,steel strips.

Both Prime and Second Quality Are Available!!!

- Q: How does tinplate contribute to the overall sustainability of packaging?

- Tinplate contributes to the overall sustainability of packaging in several ways. Firstly, tinplate is highly recyclable, meaning that it can be reused and repurposed indefinitely without losing its quality. This reduces the demand for virgin materials and minimizes the environmental impact of packaging production. Additionally, tinplate has excellent barrier properties, which helps protect the contents of the packaging from spoilage, extending their shelf life and reducing food waste. Furthermore, tinplate is lightweight yet durable, allowing for efficient transportation and reducing carbon emissions associated with logistics. Finally, tinplate has a long lifespan and can be reused in various forms, making it a more sustainable choice compared to other packaging materials.

- Q: Can tinplate be customized with different designs or logos?

- Yes, tinplate can be customized with different designs or logos. It is a versatile material that can be decorated using various printing techniques such as lithography, offset printing, or embossing. This allows for the creation of unique and personalized designs on tinplate, making it suitable for branding and promotional purposes.

- Q: What is the process of two cold rolling of tinplate?

- Tin plays a major role in preventing corrosion and rusting. It will be the steel strength and formability and corrosion resistance of tin soldering, and beautiful appearance with a material, corrosion resistant, non-toxic, high strength and good ductility properties.

- Q: How does tinplate compare to glass packaging?

- Tinplate packaging offers several advantages over glass packaging. Firstly, tinplate is much lighter than glass, making it easier and more cost-effective to transport. Additionally, tinplate is highly durable and resistant to breakage, which ensures product safety and reduces the risk of damage during handling or shipping. Furthermore, tinplate can be easily shaped and molded into various forms, allowing for greater design flexibility. Lastly, tinplate is recyclable, making it a more sustainable and environmentally friendly option compared to glass.

- Q: Can tinplate be used for packaging household products?

- Yes, tinplate can be used for packaging household products. Tinplate is a type of steel coated with a thin layer of tin, which provides excellent protection against moisture, corrosion, and tampering. It is commonly used for packaging food, beverages, and other household products due to its durability, recyclability, and ability to maintain product freshness.

- Q: How does tinplate contribute to the shelf life of canned products?

- Tinplate contributes to the shelf life of canned products through its ability to prevent corrosion and maintain product quality. The tin coating on the steel substrate acts as a barrier, protecting the can from rusting and preventing any reaction between the metal and the food inside. This helps to maintain the integrity of the can, ensuring that it doesn't leak or become contaminated. As a result, tinplate cans can effectively preserve the freshness, taste, and nutritional value of the canned products, extending their shelf life significantly.

- Q: Cookies with tinplate packaging has what advantage

- Tinplate has obvious superiority compared with other packaging materials.

- Q: Tin can weldingHow can the side of the column of the pop top be welded or pressed?,

- Mainly divided into the tank, the tank cover and the tank bottom three parts. The tank body is made of a piece of iron material through the curl bending machine, by using copper welder and welding. Now the mainstream of aerosol cans, food cans and beverage cans are produced by this method.

- Q: Why tinned fruit cans, some snow wall, and some inner wall does not appear?

- The same is canned fruit, tin cans taste more than glass bottles, why is it better? Because the storage process is completely isolated from the sun, so that it can retain the original flavor of canned fruit.

- Q: How does tinplate contribute to the safety of toys?

- Tinplate contributes to the safety of toys by providing a protective coating that prevents direct contact between the toy and any potentially harmful substances. This coating acts as a barrier against corrosion, ensuring that the toy remains safe and free from any toxic materials that may be present in the metal or paint used. Additionally, tinplate is durable and resistant to damage, reducing the risk of children being exposed to sharp edges or broken pieces.

Send your message to us

Quality of Tin Free Steel TFS

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords