Quality Electrolytic Tinplate Coils or Sheets For Tin Containers

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Quality Electrolytic Tinplate Coils or Sheets For Tin Containers Description

Electrolytic Tinplate, is one thin steel sheet with a coating of tin applied by electrolytic deposition. Tinplate made by this process is essentially a sandwich in which the central core is strip steel. This core is cleaned in a pickling solution and then fed through tanks containing electrolyte, where tin is deposited on both sides. As the strip passes between high-frequency electric induction coils, it is heated so that the tin coating melts and flows to form a lustrous coat.

2.Main Features of the Quality Electrolytic Tinplate Coils or Sheets For Tin Containers

Formability and strength – Tinplates have got very good formability and strength. By selecting a proper temper grade, appropriate formability is obtained for different applications as well as the required strength after forming.

Corrosion resistance – Tinplate has got good corrosion resistance. By selecting a proper coating weight, appropriate corrosion resistance is obtained against container contents. Coated items should meet 24 hour 5 % salt spray requirement.

Hygienic – Tin coating provides good and non toxic barrier properties to protect food products from impurities, bacteria, moisture, light and odours.

Safe – Tinplate being low weight and high strength makes food cans easy to ship and transport.

Tin is not good for low temperature applications since it changes structure and loses adhesion when exposed to temperatures below – 40 deg C.

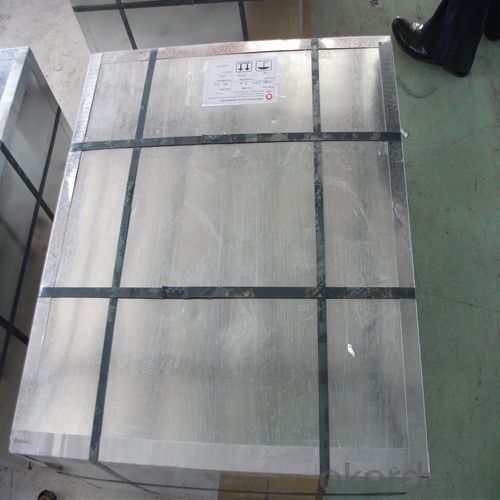

3.Quality Electrolytic Tinplate Coils or Sheets For Tin Containers Images

4.Quality Electrolytic Tinplate Coils or Sheets For Tin Containers Specification

Specification of :

Standard: ISO 11949 -1995, GB/T2520-2000,JIS G3303,ASTM A623, BS EN 10202

Material: MR,SPCC

Thickness:0.15mm - 0.50mm

Width: 600mm -1150mm

Temper: T1-T5

Annealing: BA & CA

Coil Inner Diameter: 508mm

Weight: 6-10 tons/coil 1~1.7 tons/sheets bundle

Passivation:311

Oil: DOS

Surface: Finish,bright,stone,matte,silver

5.FAQ of Quality Electrolytic Tinplate Coils or Sheets For Tin Containers

- How are the tinplates specified?

The tinplates are specified as per the steel base, extent of tempering, the coating weight, annealing method and the surface finish.

- How many types there are for base steels?

The base steels are of three types: Type MR, L, D

- Q: How does tinplate packaging handle exposure to moisture?

- Tinplate packaging has excellent resistance to moisture, making it highly suitable for protecting products from humidity and preventing damage caused by exposure to moisture.

- Q: What are the different types of tinplate containers available?

- There are several different types of tinplate containers available, including cans, tins, boxes, and drums. These containers can vary in size, shape, and functionality, and are commonly used for packaging food, beverages, chemicals, and other products.

- Q: What are the applications of tinplate?

- Tinplate has various applications, primarily in the packaging industry. It is commonly used to make food and beverage cans, as it provides a protective barrier against moisture, oxygen, and light. Tinplate is also used for making aerosol cans, paint cans, and containers for cosmetics and pharmaceutical products. Additionally, it is utilized in the manufacturing of metal caps and closures for bottles and jars.

- Q: How does tinplate compare to tin-free steel in terms of properties and applications?

- Tinplate and tin-free steel differ in terms of properties and applications. Tinplate has a thin tin coating on its surface, providing excellent corrosion resistance and a shiny appearance. It is commonly used in food and beverage packaging, as well as for decorative purposes. On the other hand, tin-free steel lacks the tin coating and is typically coated with other materials like chromium or polymer. It offers better paint adhesion and is often used in applications such as automotive parts, electrical appliances, and construction materials. Therefore, the choice between tinplate and tin-free steel depends on the specific requirements and intended applications.

- Q: Is tinplate magnetic?

- Yes, tinplate is magnetic.

- Q: How does tinplate contribute to the aesthetics of furniture?

- Tinplate contributes to the aesthetics of furniture by adding a unique and eye-catching element to its design. With its shiny and reflective surface, tinplate can create a modern and sophisticated look. It can be used for various decorative purposes, such as accents, inlays, or even as a complete surface finish, enhancing the overall visual appeal of furniture. Additionally, tinplate is versatile and can be easily shaped or embossed, allowing for intricate and detailed designs, further enhancing the aesthetics of furniture pieces.

- Q: How is tinplate used in the automotive industry?

- Tinplate is commonly used in the automotive industry for various applications such as body panels, fuel tanks, and exhaust systems. It provides a durable and corrosion-resistant coating that helps protect the metal from rust and other environmental factors, ensuring the longevity of the vehicle. Additionally, tinplate can be easily formed and shaped, making it an ideal material for producing intricate automotive components.

- Q: What are the advantages of using tinplate for stationery and office supplies?

- One of the advantages of using tinplate for stationery and office supplies is its durability. Tinplate is known for its resistance to corrosion, making it long-lasting and suitable for items that are frequently used or handled. Additionally, tinplate provides a smooth and glossy surface, enhancing the aesthetic appeal of stationery and office supplies. Its malleability allows for intricate designs, making it suitable for customizations and branding. Lastly, tinplate is a sustainable option as it is recyclable, contributing to eco-friendly practices in the stationery and office supply industry.

- Q: What are the common quality standards for tinplate?

- The common quality standards for tinplate include factors such as the thickness and uniformity of the tin coating, the absence of defects like scratches or dents, the adhesion of the tin coating to the base metal, and the overall dimensional and mechanical properties of the tinplate.

- Q: What are the safety regulations for using tinplate in food packaging?

- The safety regulations for using tinplate in food packaging vary depending on the region and country. However, generally, tinplate used in food packaging must meet strict standards set by regulatory bodies such as the Food and Drug Administration (FDA) in the United States or the European Food Safety Authority (EFSA) in Europe. These regulations typically cover factors such as the composition of the tinplate, its resistance to corrosion and leaching, and its suitability for contact with different types of food products. Manufacturers are required to comply with these regulations to ensure the safety of consumers and the integrity of the packaged food.

Send your message to us

Quality Electrolytic Tinplate Coils or Sheets For Tin Containers

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords