Electrolytic Tinplate Coils or Sheets for Metal Tin Cans

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Electrolytic Tinplate Coils or Sheets for Metal Tin Cans Description

Tinplate is a thin steel sheet coated by tin. It has an extremely beautiful metallic luster as well as excellent properties in corrosion resistance, solderability, and weldability.

2.Main Features of the Electrolytic Tinplate Coils or Sheets for Metal Tin Cans

Tinplate is used for making all types of containers such as food cans, beverage cans, 18-liter cans, and artistic cans. Its applications are not limited to containers; recently, tinplate has also been used for making electrical machinery parts and many other products.

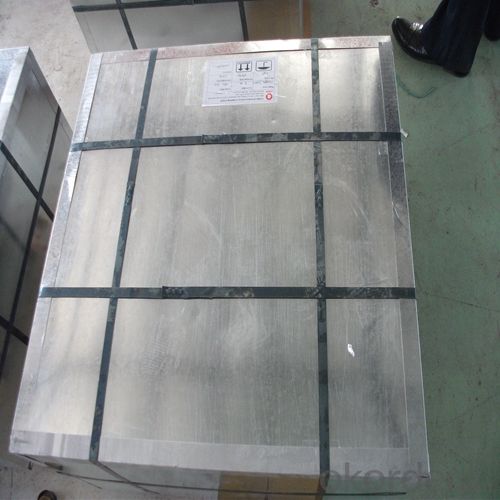

3.Electrolytic Tinplate Coils or Sheets for Metal Tin Cans Images

4.Electrolytic Tinplate Coils or Sheets for Metal Tin Cans Specification

Specification of :

Standard: ISO 11949 -1995, GB/T2520-2000,JIS G3303,ASTM A623, BS EN 10202

Material: MR,SPCC

Thickness:0.15mm - 0.50mm

Width: 600mm -1150mm

Temper: T1-T5

Annealing: BA & CA

Coil Inner Diameter: 508mm

Weight: 6-10 tons/coil 1~1.7 tons/sheets bundle

Passivation:311

Oil: DOS

Surface: Finish,bright,stone,matte,silver

5.FAQ of Electrolytic Tinplate Coils or Sheets for Metal Tin Cans

- How are the tinplates specified?

The tinplates are specified as per the steel base, extent of tempering, the coating weight, annealing method and the surface finish.

- How many types there are for base steels?

The base steels are of three types: Type MR, L, D

- Q: How does tinplate affect the overall product freshness?

- Tinplate, due to its excellent barrier properties, helps to preserve the freshness and quality of products. It prevents oxygen and moisture from entering the packaging, thereby reducing the risk of spoilage, deterioration, or contamination. This ensures that the product remains fresh and maintains its desired characteristics for an extended period.

- Q: What are the benefits of using tinplate for pharmaceuticals?

- Tinplate offers several benefits for pharmaceutical packaging. Firstly, it provides excellent protection against light, moisture, and oxygen, ensuring the quality and stability of pharmaceutical products. Secondly, tinplate is a durable and robust material that offers resistance to corrosion, making it suitable for long-term storage. Additionally, tinplate is easily moldable, allowing for various shapes and sizes of packaging, including child-resistant closures. Lastly, tinplate is 100% recyclable, making it an environmentally friendly choice for pharmaceutical companies.

- Q: How is tinplate coated with organic materials for specific applications?

- Tinplate is coated with organic materials for specific applications through a process known as lacquering. Lacquering involves applying a thin layer of organic material, such as a resin or polymer, onto the surface of the tinplate. This coating provides protection against corrosion, enhances the aesthetic appearance, and improves the adhesion of inks or paints for printing or labeling purposes. The organic coating can be applied through various methods like roll coating, spray coating, or electrostatic deposition, depending on the specific requirements of the application.

- Q: How does tinplate perform in terms of tamper-evident features?

- Tinplate performs well in terms of tamper-evident features. It is a durable material that can be easily sealed to prevent tampering. The metal construction of tinplate makes it difficult to manipulate or break without leaving visible signs of tampering, making it an excellent choice for packaging goods that require tamper-evident features.

- Q: What are the main applications of tinplate in the agricultural industry?

- Tinplate is commonly used in the agricultural industry for its various applications such as packaging and storage of agricultural products, manufacturing of containers for fertilizers and pesticides, as well as for agricultural machinery components due to its corrosion-resistant properties.

- Q: How does tinplate contribute to the durability of stationery products?

- Tinplate contributes to the durability of stationery products by providing a protective and corrosion-resistant coating. This coating helps prevent rust and damage from moisture, ensuring that the stationery items remain in good condition for a longer period of time. Additionally, tinplate's strength and rigidity enhance the overall durability of stationery products, making them less prone to bending, crushing, or breaking during use or transportation.

- Q: How does tinplate compare to other packaging materials in terms of cost?

- Tinplate is generally more expensive than other packaging materials such as aluminum or plastic.

- Q: What are the main applications of tinplate in the aerospace industry?

- Tinplate is commonly used in the aerospace industry for various applications such as manufacturing aircraft components, including fuel tanks, hydraulic systems, and electrical connectors. Its corrosion-resistant properties make it ideal for protecting these components from environmental factors, ensuring their longevity and reliability. Additionally, tinplate's high strength-to-weight ratio makes it an excellent choice for lightweight construction, contributing to fuel efficiency and overall aircraft performance.

- Q: What are the main trends in tinplate recycling?

- The main trends in tinplate recycling include increased awareness and adoption of recycling initiatives, technological advancements in sorting and processing methods, and the promotion of circular economy principles to minimize waste and maximize resource efficiency.

- Q: How can the section of the tinplate be maintained without rust?

- The cross section of the tinplate is free of rust. Both sides have plating, the cross section can use lubricating oil

Send your message to us

Electrolytic Tinplate Coils or Sheets for Metal Tin Cans

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords