Prime Quality Electrolytic Tinplate Sheets or Coils in Low Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 7000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Electrolytic tinplate (ETP) sheets in low price Description

Electrolytic Tin Plate Coils and Sheets for Foods Metal Packaging, is one thin steel sheet with a coating of tin applied by electrolytic deposition. Tinplate made by this process is essentially a sandwich in which the central core is strip steel. This core is cleaned in a pickling solution and then fed through tanks containing electrolyte, where tin is deposited on both sides. As the strip passes between high-frequency electric induction coils, it is heated so that the tin coating melts and flows to form a lustrous coat.

2.Main Features of the Electrolytic tinplate (ETP) sheets in low price

Steady and high quality

Fast shipment

Good experience for export work

For the surface, Plate uniform in thickness,uniform and smooth tin coating, without flaws,rusts,scratch,wave,nick of tin coating etc.

Price competitive

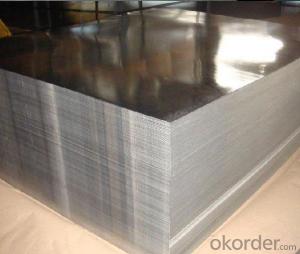

3.Electrolytic tinplate (ETP) sheets in low price Images

4.Electrolytic tinplate (ETP) sheets in low price Specification

Standard | ISO 11949 -1995, GB/T2520-2000,JIS G3303,ASTM A623, BS EN 10202

|

Material | MR,SPCC |

Thickness | 0.15mm - 0.50mm |

Width | 600mm -1150mm |

Temper | T1-T5 |

Annealing | BA & CA |

Coil Inner Diameter | 508mm |

Weight | 6-10 tons/coil 1~1.7 tons/sheets bundle |

Passivation | 311 |

Oil | DOS |

Surface | Finish,bright,stone,matte,silver |

5.FAQ of Electrolytic tinplate (ETP) sheets in low price

-How to place .an order or contact you ?

Please send us Email. we will give you a quick response in seconds .

- How is your quality ?

All our quality is prime even the secondary quality . We have many years experience

In this field with serious quality control standard . Advanced equipment, We welcome your visit to our factory .

- Q: Who knows the process of tinplate production?

- The basic production process of tinplate: pickling cold rolling cut I skim -- > I I I I I of Kaiping tin flat temperingTropical pickling: hot rolled coils must be pickled before cold rolling to produce cold rolling

- Q: How does tinplate perform in terms of tamper-evident features?

- Tinplate performs exceptionally well when it comes to tamper-evident features. Its strong and durable nature makes it difficult to manipulate or tamper with once sealed. Additionally, tinplate can be easily embossed or printed with intricate designs, making it easier to spot any signs of tampering. Overall, tinplate provides reliable protection against tampering, ensuring the integrity and safety of the contents inside.

- Q: Tin and tinSince the back skin as long as tinplate will rust, so why not replace tin?

- Oftinned is actually, tinplate, commonly used in food and beverage packaging, have good anti-corrosion effect, and no harm to human body. We used a lot of tinplate cans, is done. The tinplate back skin, is actually the plate above the tin, is physical effect eroded, so the steel will rust.

- Q: What are the safety regulations for tinplate packaging?

- The safety regulations for tinplate packaging vary depending on the specific industry and region. However, some common safety regulations include ensuring that the tinplate packaging is free from sharp edges or protrusions that could cause injury, conducting regular quality control checks to ensure the integrity of the packaging, and adhering to specific guidelines for handling and storing tinplate packaging to prevent accidents or contamination.

- Q: Can tinplate be embossed?

- Yes, tinplate can be embossed.

- Q: How to quickly open the bottle?

- Put the tins of canned fruits soaked in hot water for 3-5 minutes, so that the tank gas temperature rises, the pressure is increased, which is the principle of expansion and contraction. Turn the canned fruit bottle upside down for a while. When the liquid in it breaks down the vacuum inside and outside, tap it in the bottom with your palm and pull it gently. It's easy to pull apart.

- Q: Are there any limitations to using tinplate packaging?

- Yes, there are several limitations to using tinplate packaging. Firstly, tinplate packaging is relatively expensive compared to other packaging materials such as plastic or cardboard. Additionally, tinplate packaging is heavier and bulkier, which can increase transportation costs. Tinplate is also more susceptible to corrosion, especially in high humidity or acidic environments. Lastly, tinplate is not as flexible as other materials, making it less suitable for certain packaging designs or shapes.

- Q: What are the safety considerations when handling tinplate?

- When handling tinplate, it is essential to consider several safety measures. First, tinplate can have sharp edges, so wearing gloves and using appropriate tools is important to avoid cuts or injuries. Secondly, tinplate is often coated with various substances, such as lacquer or resin, which may contain harmful chemicals. Therefore, it is crucial to handle tinplate in well-ventilated areas and wear protective equipment like goggles and masks to minimize exposure. Additionally, tinplate can be heavy and bulky, so proper lifting techniques should be employed to prevent strains or back injuries. Lastly, storing tinplate in a dry and clean area can help prevent corrosion and maintain its structural integrity.

- Q: What are the main factors influencing the growth of the tinplate market?

- The main factors influencing the growth of the tinplate market include increasing demand for packaged food and beverages, the growth of the automotive industry, rising consumer awareness about sustainable packaging, and advancements in tinplate manufacturing technologies. Additionally, factors such as changing lifestyles, urbanization, and the need for lightweight and durable packaging solutions are also driving the growth of the tinplate market.

- Q: What are the different types of tinplate coatings available?

- There are several types of tinplate coatings available, including electrolytic tinplate (ETP), tin-free steel (TFS), and black plate. ETP is the most commonly used and consists of a thin layer of tin on both sides of the steel substrate. TFS, on the other hand, does not have a tin coating but is instead coated with a layer of chromium or chromium oxide. Black plate refers to steel that has not been coated with any protective layer and is typically used for industrial applications.

Send your message to us

Prime Quality Electrolytic Tinplate Sheets or Coils in Low Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 7000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords