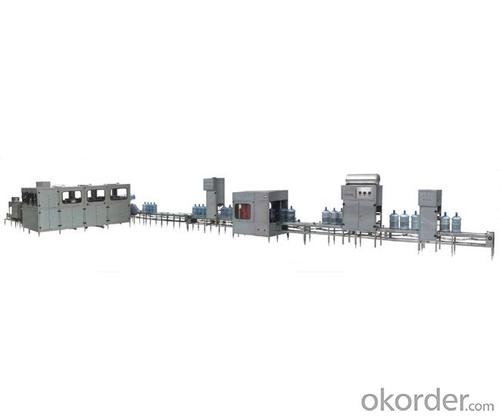

QGF series drum filling production line QGF-600

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Chenyu Packing is a professional company specializing in R & D, manufacturing, technical service and sales of beer and beverage packing machinery.

Among the products, RCGF series, CGF series, DCGF series bottle packing and QGF series barrel packing beverage production lines and QHS series beverage mixer are all designed and made on the base of importing the advanced technology from German, Italy and Japan and its technology keeps the same level as international.

Also the company provides technical consultation, factory planning, installing and adjusting technological train and other services.

QGF series drum filling production line:

Usage:

It is especially used in 3 gallons, 5 gallons drum-packed pure water, washing, filling and capping.

Characteristics:

The parts touching with water adopt high-quality stainless stee. The cylinder gear runs smoothly and the fixed position is correct. It adopts inserting-type washing technology to remove washing blind angle.

Main Technical Parameters:

Machine | Model | QGF-120 | QGF-240 | QGF-300 | QGF-400 | QGF-600 |

Capacity | 120 | 240 | 360 | 480 | 600 | |

Filling head | 1 | 2 | 3 | 4 | 5 | |

Overall size | 3700*1600*1800 | 4000*1500*1800 | 4000*1580*1800 | 4000*1580*1800 | 5000*1850*1900 | |

Power | Main machine | 3.8 | 6.8 | 8.8 | 11 | 11 |

Heating(kw) | 9 | 10 | 12 | 12 | ||

Compressed air | Air pressure | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 |

Air consumption | 0.2 | 0.2 | 0.3 | 0.4 | 0.5 | |

Lye | Inside rinse | 20s*2 | 20s*2 | 20s*2 | 20s*2 | 20s*2 |

Outside spray | 20s*1 | 20s*1 | 20s*1 | 20s*1 | 20s*1 | |

Circle water | Inside rinse | 20s*2 | 20s*2 | 20s*2 | 20s*2 | 20s*2 |

Outside spray | 20s*1 | 20s*1 | 20s*1 | 20s*1 | 20s*1 | |

Sterilizing water | Inside rinse | 20s*2 | 20s*2 | 20s*2 | 20s*2 | 20s*2 |

Outside spray | 20s*1 | 20s*1 | 20s*1 | 20s*1 | 20s*1 | |

Pure water | Inside rinse | 20s*2 | 20s*2 | 20s*2 | 20s*2 | 20s*2 |

Outside spray | 20s*1 | 20s*1 | 20s*1 | 20s*1 | 20s*1 | |

Pure water | 600 | 1000 | 1500 | 2000 | 2500 | |

- Q: Vacuum packing machine for cooked food: can whole chicken, whole goose and whole duck be packed?

- Well, yesBut the vacuum packaging machines used for different product sizes are different

- Q: Bread packing machine Product features

- Product features1. double frequency control, bag length is cut, no need to adjust the empty walk, one step in place, save time and save the film.2. man-machine interface, parameter setting is convenient and quick.3. fault diagnosis function, clear failure display.

- Q: What are the packing machines?

- They make packing equipment. There are many kinds of food packaging, sealing packaging, pillow type packaging machine. I hope I can help you.

- Q: A & B two sets of packaging machines, at the same time packaging quality of 500 kilograms of goods

- (1) calculate the average of two samples;(2) the variance of two samples was calculated;(3) which packaging machine is more stable in packing quality?(1) according to the average, the number divided by the sum of each group;

- Q: What's the best place to use the pillow type packing machine?

- This device is now relatively mature technology, but each manufacturer's design is still a little different

- Q: How much is the tableware wrapping machine?What's the price of the tableware wrapping machine?

- Tableware packaging machine packaging production, simple operation and high degree of automation, high efficiency, low packing cost, save labor, reduce the damage and the characteristics of two pollution, by tableware shrink packaging is widely used in all kinds of, is a very mature model

- Q: How does the pulp solidify? What additives do you need? Curing agents? Or what do you need as binders?

- Urea formaldehyde resin is a water-soluble resin, easily cured, the cured resin colorless, non-toxic, good light resistance, long-term use does not change color, heat molding will not change color, can add various colorants to prepare various brightly colored products.Urea formaldehyde resin is hard, scratch resistant, weak acid, weak base and grease. It is cheap and has certain toughness, but it is easy to absorb water, so it has poor water resistance and electrical properties, and its heat resistance is not highThe use of urea formaldehyde resin is widely used in plastic, mold, laminated plastic, foam, also can be used for the production of water-soluble adhesive, the adhesive for wood; fabric shrinkproof and crepe treatment agent; used as a varnish of paper, in order to improve the wet strength of paper. The following is a simple Shaoxing on it the application of the plastic.

- Q: Food, equipment, tools, containers, packaging materials, etc. shall comply with food safety standards or requirements

- Hygienic standard for polyethylene terephthalate resin for GB 13114 food containers and packaging materialsGB, 13113-1991. Hygienic standard for polyethylene terephthalate molded articles for food containers and packaging materials

- Q: Energy saving reform of packaging machine

- First, the working principle of food packaging machinePillow type automatic packaging machine of the present domestic leading and most mature and reliable design and production technology, the essence of a collection of many years of experience in the field of packaging machinery, the packing machine can be used in a variety of composite packaging film coil on the packaging of bulk food, very suitable for the majority of users need to Chinese. 1) the electrical parts of the automatic packing machine are usually made up of the following parts:

- Q: Calendering, extrusion, blow molding, pressing, plastic (vacuum forming) and what is the rotational molding

- Plastic forming and processing methodPlastic molding is an engineering technology, involves the plastic into all kinds of plastic products in the process. The transformation process tends to happen in one or more of the following conditions, such as polymer rheology and physical and chemical properties of the change.

Send your message to us

QGF series drum filling production line QGF-600

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords