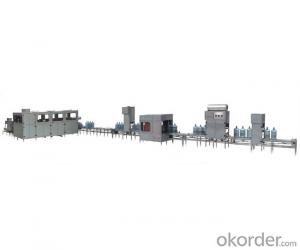

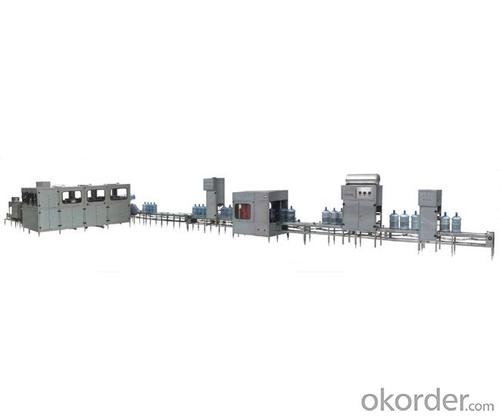

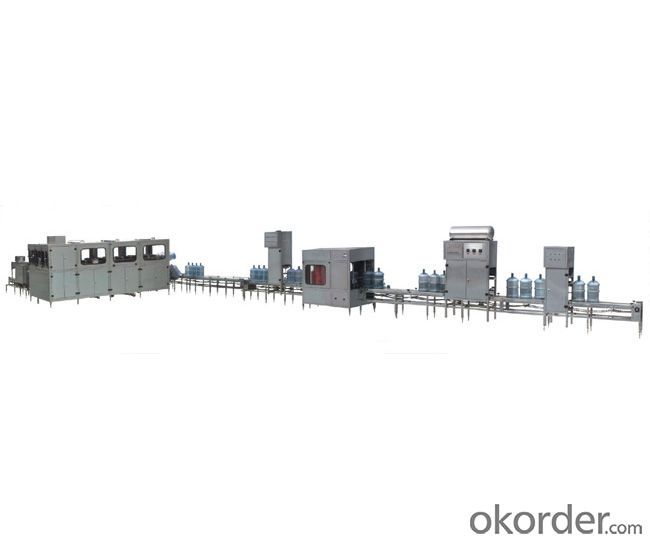

QGF Series Drum Filling Production Line QGF-400

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

CMAX Packing is a professional company specializing in R & D, manufacturing, technical service and sales of beer and beverage packing machinery.

Among the products, RCGF series, CGF series, DCGF series bottle packing and QGF series barrel packing beverage production lines and QHS series beverage mixer are all designed and made on the base of importing the advanced technology from German, Italy and Japan and its technology keeps the same level as international.

Also the company provides technical consultation, factory planning, installing and adjusting technological train and other services.

QGF series drum filling production line:

Usage:

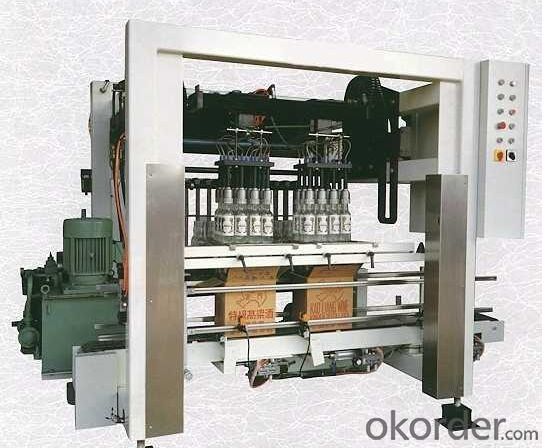

It is especially used in 3 gallons, 5 gallons drum-packed pure water, washing, filling and capping.

Characteristics:

The parts touching with water adopt high-quality stainless stee. The cylinder gear runs smoothly and the fixed position is correct. It adopts inserting-type washing technology to remove washing blind angle.

Main Technical Parameters:

Machine | Model | QGF-120 | QGF-240 | QGF-300 | QGF-400 | QGF-600 |

Capacity | 120 | 240 | 360 | 480 | 600 | |

Filling head | 1 | 2 | 3 | 4 | 5 | |

Overall size | 3700*1600*1800 | 4000*1500*1800 | 4000*1580*1800 | 4000*1580*1800 | 5000*1850*1900 | |

Power | Main machine | 3.8 | 6.8 | 8.8 | 11 | 11 |

Heating(kw) | 9 | 10 | 12 | 12 | ||

Compressed air | Air pressure | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 |

Air consumption | 0.2 | 0.2 | 0.3 | 0.4 | 0.5 | |

Lye | Inside rinse | 20s*2 | 20s*2 | 20s*2 | 20s*2 | 20s*2 |

Outside spray | 20s*1 | 20s*1 | 20s*1 | 20s*1 | 20s*1 | |

Circle water | Inside rinse | 20s*2 | 20s*2 | 20s*2 | 20s*2 | 20s*2 |

Outside spray | 20s*1 | 20s*1 | 20s*1 | 20s*1 | 20s*1 | |

Sterilizing water | Inside rinse | 20s*2 | 20s*2 | 20s*2 | 20s*2 | 20s*2 |

Outside spray | 20s*1 | 20s*1 | 20s*1 | 20s*1 | 20s*1 | |

Pure water | Inside rinse | 20s*2 | 20s*2 | 20s*2 | 20s*2 | 20s*2 |

Outside spray | 20s*1 | 20s*1 | 20s*1 | 20s*1 | 20s*1 | |

Pure water | 600 | 1000 | 1500 | 2000 | 2500 | |

FAQ:

1. why chose us?

China National Building Materials (Group) Corporation (CNBM), established in 1984,now is one of the largest state-owned group corporation in China, dealing with building materials & industrial equipment. Up to year 2010, CNBM Group's total asset is 20 billion USD and total staff is more than 100,000.CNBM International Corporation, specializes in designing & manufacturing of various

kinds of construction machinery, including tower crane, building hoist, etc. All the equipment produced by CNBM are compliant with the National level quality standard, and wins great reputation for their endurable performance in worldwide markets.

2.How about the shipment?

The delivery time is 20 days.

3. What about your service?

We have our factory, we can meet customers needs as soon as possible.

We have first rate professional technology and provide good after-sales service.

- Q: What are the main functions of packaging machinery?

- Eight main functions of packaging machinery and equipmentPacking is a necessary condition for products to enter the circulation field

- Q: What is the price of a small jujube packing machine?

- Mainly see what some requirements, automatic metering packaging or vacuum packaging machine, after understanding can determine the price.

- Q: What kind of reducer is commonly used in packaging machinery?

- Generally speaking, gear reducer, planetary gear reducer, and the most common one, these equipment power is relatively small, and some need to take the brakes of the motor reducer

- Q: Color code positioning of packaging machinery

- The use of the printed color packaging materials, photoelectric switch (available on the color electric eye tracking and positioning), through the control system to drive the stepper motor rotation and color according to the distance between the automatic stop, to complete and accurate packaging products logo.

- Q: Whether you can press paper plastic molding after PET

- Another hot pressing mould pressing needs, blister sealing machine uses a plastic bakelite mold mold, high frequency plastic welding machine is used Aluminum Alloy mold. The size of the mold needs to be determined by blister.

- Q: Which friend is an expert in mechanical equipment or a better understanding of sealing machines? Tell me how to identify the equipment

- Take the food packaging machine for example, if only from the hardware, then you can ask when you buy the degree of automation, semi-automatic or fully automatic, the use of steel ah,

- Q: What is the working principle of the pillow packing machine?

- Some packaging machinery manufacturers, many varieties of products, in the purchase of packaging machines, I hope a device can pack all their own varieties

- Q: What does the mechanical equipment include?

- Hydraulic lifting track machineHydraulic tamping machine, rail sawing machine, rail machine

- Q: Donkey hide gelatin cake made of sticky, forming very well, that is, vacuum packaging, after a little sticky in the vacuum bag, what's going on?

- Now the standard of living has improved, basically the vacuum bag. This will improve the product's shelf life, preservation time is longer, more conducive to product sales.

- Q: Calendering, extrusion, blow molding, pressing, plastic (vacuum forming) and what is the rotational molding

- Plastic forming and processing methodPlastic molding is an engineering technology, involves the plastic into all kinds of plastic products in the process. The transformation process tends to happen in one or more of the following conditions, such as polymer rheology and physical and chemical properties of the change.

Send your message to us

QGF Series Drum Filling Production Line QGF-400

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords