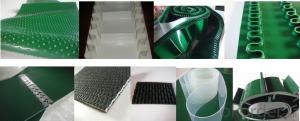

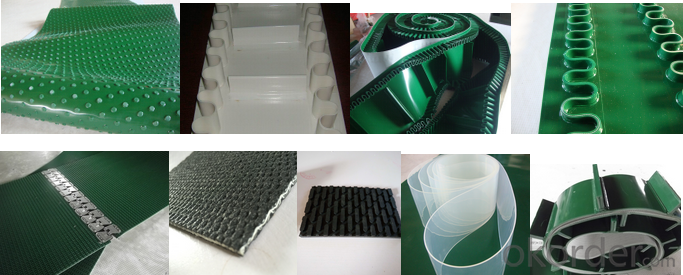

PVC/PU Conveyor Belt with Sidewall Cleats and Guide for Light Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC/PU Conveyor Belt with Sidewall Cleats and Guide for Light Industry

PVC/PU Conveyor Belt

Light duty conveyor belts are manufactured for all applications with various fabrics impregnation like polyester, nylon, cotton, solid woven, fiberglass etc. Belts are available in different colors like green, white, black, blue and thickness from 0.5 mm to 15 mm up to 3500 mm width and with top surface coating Rubber, PVC, PU, TPU, PE, TPEE, Teflon, Silicone, etc.

Colors: red, yellow, green, blue, gray, white, black, blue, green, transparent (in general we have)

Thickness: PVC (1~7mm) PU (0.8~4mm)

Appearance: flat surface, diamond pattern, lawn pattern, golf pattern etc.

Advantages: PVC: economical and practical, technology is mature.

PU: applicable to the food industry, abrasion resistant and corrosion.

Subsequent machining technology: it can add baffle, skirt, sponge, guide bar.

ADVANTAGES:

Low operating noise and costs, reduced maintenance, excellent durability.

Largely impervious to oils, greases and many chemicals.

Special types give excellent grip on inclination.

Abrasion resistant - rugged, high strength - low stretch characteristic.

Light and thin, better strength / weight ratio - energy saving.

Superb tracking over great length - longitudinally flexible and laterally stiff.

Please contact us freely if you need any conveyor belt.

- Q: Can olive nets be used in high-density orchards?

- Yes, olive nets can indeed be used in high-density orchards. Olive nets are commonly used in orchards to protect the olives from birds and other animals. They are versatile and can be adapted to different orchard configurations, including high-density planting systems. The nets can be strategically installed to cover the entire canopy, providing effective protection and allowing for efficient harvesting.

- Q: How do olive nets help in reducing the use of chemical pesticides?

- Olive nets help in reducing the use of chemical pesticides by acting as a physical barrier that prevents pests, such as insects or birds, from reaching the olive trees. By keeping pests away, olive nets minimize the need for chemical pesticides to control infestations or deter birds from feeding on the olives. This allows olive growers to adopt more environmentally friendly and sustainable practices in their farming methods.

- Q: Can olive nets be used in both small and large-scale olive orchards?

- Yes, olive nets can be used in both small and large-scale olive orchards. Olive nets are versatile and can be customized to fit the size and layout of the orchard. They are commonly used to protect the olives from pests and to facilitate the collection of the fruits during harvesting, making them suitable for orchards of all sizes.

- Q: Advantages of plastic furniture

- Colorful plastic furniture lines smooth bright color, in addition to the common white, red orange yellow green blue purple...... There are all kinds of colors, and there are transparent furniture, and its bright visual effects bring people visual comfort. At the same time, because the plastic furniture is made by the mold forming, so it has remarkable characteristics of smooth lines, each round, each arc, each grid and the interface are natural and smooth, without manual traces.

- Q: Can olive nets be used on trees of different ages?

- Yes, olive nets can be used on trees of different ages. Olive nets are designed to protect the olive fruits from birds and other animals. These nets can be draped over the trees, regardless of their age, to prevent the fruits from being eaten or damaged.

- Q: Can olive nets be used to improve overall orchard efficiency?

- Yes, olive nets can be used to improve overall orchard efficiency. Olive nets effectively protect the olives from birds and other pests, reducing crop damage and loss. This leads to higher yields and improved harvest quality. Additionally, the use of olive nets can also facilitate faster and more efficient harvesting, as the olives are contained within the nets and can be easily collected.

- Q: What is the purpose of using a net in olive harvesting?

- The purpose of using a net in olive harvesting is to catch the falling olives and prevent them from hitting the ground, which can cause damage to the olives and reduce their quality. The net also makes it easier to collect the olives, as they are all contained in one place, making the harvest more efficient.

- Q: How do olive nets prevent olives from being damaged during harvesting?

- Olive nets prevent olives from being damaged during harvesting by providing a protective barrier between the olives and the ground. These nets are spread out underneath the olive trees, and as the olives are picked or shaken from the branches, they fall onto the nets instead of directly onto the hard ground. This prevents bruising or other physical damage to the olives, ensuring they remain intact and of high quality.

- Q: Do olive nets protect against birds?

- Yes, olive nets are designed to protect olive trees from birds by preventing them from accessing the fruit.

- Q: Can olive nets be used in regions with extreme weather conditions?

- Olive nets may not be suitable for regions with extreme weather conditions as they are typically designed for protecting olives from birds and insects rather than withstanding harsh weather elements.

Send your message to us

PVC/PU Conveyor Belt with Sidewall Cleats and Guide for Light Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords