PVC/PU Conveyor Belt Used in Light Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC/PU Conveyor Belt Used in Light Industry

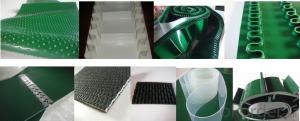

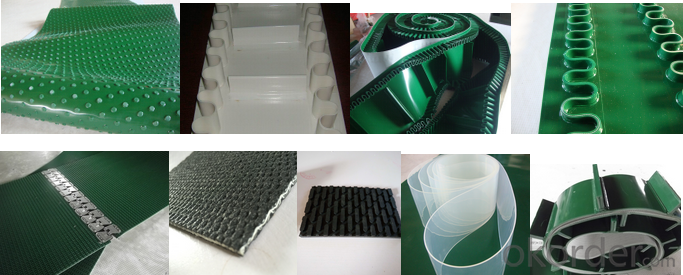

PVC/PU Conveyor Belt

Light duty conveyor belts are manufactured for all applications with various fabrics impregnation like polyester, nylon, cotton, solid woven, fiberglass etc. Belts are available in different colors like green, white, black, blue and thickness from 0.5 mm to 15 mm up to 3500 mm width and with top surface coating Rubber, PVC, PU, TPU, PE, TPEE, Teflon, Silicone, etc.

Colors: red, yellow, green, blue, gray, white, black, blue, green, transparent (in general we have)

Thickness: PVC (1~7mm) PU (0.8~4mm)

Appearance: flat surface, diamond pattern, lawn pattern, golf pattern etc.

Advantages: PVC: economical and practical, technology is mature.

PU: applicable to the food industry, abrasion resistant and corrosion.

Subsequent machining technology: it can add baffle, skirt, sponge, guide bar.

ADVANTAGES:

Low operating noise and costs, reduced maintenance, excellent durability.

Largely impervious to oils, greases and many chemicals.

Special types give excellent grip on inclination.

Abrasion resistant - rugged, high strength - low stretch characteristic.

Light and thin, better strength / weight ratio - energy saving.

Superb tracking over great length - longitudinally flexible and laterally stiff.

Product Feature

*Anti-static and non-conductive

*Food quality types to FDA standards

*Resistance to abrasion, oils, fats and chemicals

*Surfaces with low, medium or high coefficient of friction

*High transverse rigidity and dimensional stability

* Low noise (LdB belts)

* Working temperature ranges from -10 to 80Deg.C

Please contact us freely if you need any conveyor belt.

- Q: Can olive nets be used on trees with multiple trunks?

- Yes, olive nets can be used on trees with multiple trunks. Olive nets are designed to cover and protect the entire canopy of the tree, regardless of the number of trunks. The nets can be draped over the tree and secured to the ground, ensuring that all the olives are collected without damaging the multiple trunks.

- Q: Can olive nets be used on olive trees grown in cold climates?

- Yes, olive nets can be used on olive trees grown in cold climates. Olive nets are commonly used to protect olive trees from extreme weather conditions, including frost and wind. By covering the trees with nets, the cold air is trapped, creating a microclimate that helps to maintain warmer temperatures around the trees. This can be particularly beneficial for olive trees grown in cold climates, as it helps to prevent frost damage and promotes healthy growth.

- Q: Can olive nets be used in olive groves with high bird populations?

- Olive nets can be used in olive groves with high bird populations as they are specifically designed to protect the olives from being eaten by birds. These nets act as a physical barrier, preventing birds from accessing the fruit. However, it is important to regularly monitor and maintain the nets to ensure their effectiveness and prevent any entanglement of birds.

- Q: What harm does it take to eat hot food with plastic?

- If a plastic bag containing more than 50~60 degrees of food is used, the lead in the bag will dissolve into the food, and the plastic bag will release poisonous gas and invade into the food. Long term intake of the human body can seriously impair health and cause disease. Especially hot food, high temperature will make the poisonous substances in plastic absorbed by food, once entered the body will cause accumulation of towel poison, so when the hot food, must not mess with plastic bags.

- Q: Can olive nets be used in combination with soil erosion control measures?

- Yes, olive nets can be used in combination with soil erosion control measures. Olive nets are typically used to protect olive trees from birds and collect fallen olives, but they can also help prevent soil erosion by reducing the impact of raindrops on the soil surface and promoting water infiltration. Additionally, when properly installed, olive nets can act as a physical barrier that helps retain soil on slopes, further enhancing erosion control efforts.

- Q: Are there any specific safety precautions to consider when using olive nets?

- Yes, there are several safety precautions to consider when using olive nets. Firstly, it is important to wear appropriate protective gear such as gloves and eye protection to avoid any potential injuries. Additionally, ensure that the nets are securely fastened and properly maintained to prevent accidents. Be cautious while setting up or dismantling the nets to avoid tripping or falling. Lastly, be mindful of the weight and size of the olives collected in the nets to prevent strain or injury while handling or transporting them.

- Q: How do olive nets prevent olive contamination from the ground?

- Olive nets prevent olive contamination from the ground by creating a physical barrier between the olives and the soil. These nets are spread underneath the olive trees, effectively catching the falling olives and preventing direct contact with the ground. This helps to avoid potential contamination from dirt, dust, pests, or any other impurities present in the soil.

- Q: Can olive nets be used to improve the profitability of olive farming?

- Yes, olive nets can be used to improve the profitability of olive farming. These nets protect the olives from pests and birds, reducing crop losses and improving the overall yield. Additionally, the nets help to maintain the quality of the olives by preventing bruising and damage during harvesting. This ultimately leads to higher profits for olive farmers.

- Q: What kind of plastic grade does polyether sulfone resin (PES) belong to?

- [heat resistance]The heat variant temperature is 200~220 DEG C, the continuous use temperature is 180~200 DEG C, and the UL temperature index is 180 DEG C.[water resistance]Up to 150 to 160 DEG C hot water or steam erosion at high temperatures from acid and alkali.[modulus of temperature, consul sex]The base modulus is almost unchanged at -100 to 200 degrees, especially above 100 DEG C, which is better than any of the thermoplastic resins.

- Q: Can olive nets be used in areas with frequent frost?

- Olive nets can be used in areas with frequent frost, but certain precautions need to be taken. The nets should be removed before the frost sets in to prevent damage to the olive trees. Additionally, using nets with a mesh size that allows air circulation can help minimize frost-related issues.

Send your message to us

PVC/PU Conveyor Belt Used in Light Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords