PVC jacket compound for CATV coaxial lines

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 3000 Tons kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC jacket compound for CATV coaxial lines

I. Type andapplication

Type | Product | Application and Cable Specification |

5623N-40 | UL60℃ Flame retardant low temp. resistant PVC jacket compound | UL60℃ Flame retardant low temp. resistant PVC jacket compound for CATV coaxial lines. CM-class flame retardant |

5823N-40 | UL80℃ Flame retardant low temp. resistant PVC jacket compound | UL80℃ Flame retardant low temp. resistant PVC jacket compound for CATV coaxial lines. CM-class flame retardant |

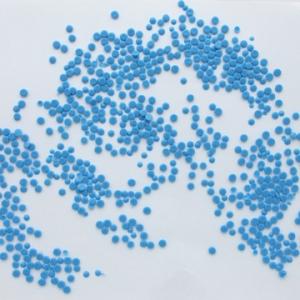

II. Productdescription

PVC jacket compound for CATV coaxial lines,based on PVC resin, is made into granula by mixing, plastification andgranulation with adding plasticizer, stabilizing agent, modifying agent,pigment and etc. The products meet various special requirements, such asdifferent hardness, UV stable, environment friend (RoHs, REACH, PAHs,chlorinated alkanes free, phthalatefree, and etc.), sub-shine and fog surface, low temperature resistant, PS/ABStransfer proof, rodent-repellent, termite-repellent, and transparent, and etc.

III. Processing

It is recommended that compound should beprocessed with common extruder having a minimum L/D ratio of 20.

The following temperature(℃) profile of extruder is recommended:

Zone | Zone 1 | Zone 2 | Zone 3 | Zone 4 | Head | Die |

Temperature ℃ | 140 | 150 | 160 | 165 | 165 | 160 |

IV. Storageand transport

Packaging:25kg/bag, PEmembrane inside bag and Kraft outside bag.

Storage and transport: Avoiding in directsunlight and weathering. The storage place should be in clean, cool, dry, andventilated conditions.

V. Properties

Table

Item | Unit | Standard Value | |

5623N-40 | 5823N-40 | ||

Tensile Strength | ≥ MPa | 13.1 | 13.8 |

Elongation at Break | ≥ % | 270 | 200 |

Impact Brittleness Temperature | ℃ | -40 | -40 |

Volume Resistivity, at 20℃ | ≥Ω﹒m | 3.7×109 | 1.0×109 |

Dielectric Strength | ≥ MV/m | 18 | 18 |

Thermal Stability Time at 200℃ | ≥ min | - | - |

Hot Deformation | ≤ % | - | - |

Oxygen Index | ≥ % | 30 | 30 |

Thermal Aging |

|

|

|

Aging Temperature | ℃ | 100±1 | 100±1 |

Aging Time | h | 168 | 240 |

Retention on Tensile Strength | ≥ % | 70 | 70 |

Retention on Elongation at Break | ≥ % | 70 | 70 |

- Q: What are the parts of plastics and what are their characteristics?

- The plastic is made of monomers as raw materials, polymer by polyaddition or polycondensation polymerization, commonly known as plastic or resin, can freely change the composition and form style, composed of synthetic resin and filler, plasticizer, stabilizer, lubricant, pigment and other additives.

- Q: Can olive nets be used in hot climates?

- Yes, olive nets can be used in hot climates. Olive nets are commonly used in regions with hot climates to protect the olive trees and collect the fallen olives during the harvesting season. The nets help shade the trees and prevent the olives from direct exposure to the scorching sun, which can improve the quality of the olives and prevent damage from excessive heat.

- Q: Can a plastic bowl be used safely?

- The long-term use of plastic bowl has certain harm to the body, often add a plastic plasticizer, which contains a number of toxic chemicals, when using a plastic bowl of hot or boiling water, it is easy to dilute toxic chemicals into the water, and the internal microscopic structure of plastic has many pores, which hides dirt the cleaning is not clean, it is easy to breed bacteria.

- Q: How does an olive net help prevent damage to the olives during harvesting?

- An olive net helps prevent damage to the olives during harvesting by providing a protective barrier that catches falling olives, preventing them from hitting the ground and getting bruised or damaged. This netting is spread out beneath the olive trees, allowing the olives to fall onto it instead of directly onto the ground. This gentle landing ensures that the olives remain intact and minimizes the risk of spoilage or contamination during the harvesting process.

- Q: What harm does plastic particles do to the body in the factory?

- Harm has the following aspects:1. dust is harmful to the lungs.2., a variety of additives will be more or less oxidized decomposition, emit harmful gases.

- Q: Do olive nets affect the taste of the olives?

- Yes, olive nets can affect the taste of olives. When olives are left on the tree for a longer period of time to ripen, they tend to have a richer and more flavorful taste. However, using olive nets to harvest olives can speed up the process and result in slightly less ripe olives, which can impact their taste.

- Q: Can olive nets be used in combination with organic pest control methods?

- Yes, olive nets can be used in combination with organic pest control methods. Olive nets are primarily used to protect olive trees and their fruits from birds and other pests. By using organic pest control methods such as beneficial insects, natural repellents, and cultural practices like crop rotation, olive nets can provide an additional layer of protection and enhance the effectiveness of organic pest control measures.

- Q: Do olive nets affect the shelf life of the olives?

- Yes, olive nets can affect the shelf life of olives. When olives are left on the tree for an extended period of time under the nets, they may become overripe or develop mold and spoilage due to increased moisture and reduced airflow. Additionally, the presence of olive nets can make it challenging to harvest the olives at the optimal time, further impacting their shelf life.

- Q: How effective are olive nets in preventing bird damage to olive trees?

- Olive nets are generally quite effective in preventing bird damage to olive trees. These nets create a physical barrier, preventing birds from accessing the trees and feasting on the olives. However, their effectiveness can vary depending on factors such as the type and size of the net, proper installation, and bird species in the area. It is important to choose the right netting and ensure its proper maintenance to achieve optimal results.

- Q: What size olive net is suitable for a small olive grove?

- The size of the olive net suitable for a small olive grove depends on the specific dimensions and layout of the grove. It is recommended to measure the dimensions of the grove and consult with a professional or experienced olive grove owner to determine the appropriate size of the net needed for effective coverage.

Send your message to us

PVC jacket compound for CATV coaxial lines

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 3000 Tons kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords