PVC free foam board mould extrusion die head Plastic Marble machinery

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Introduction

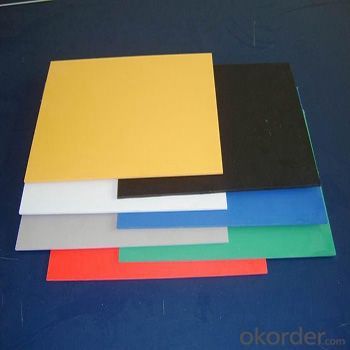

PVC foam board is made from polyvinyl chloride, with flat plate surface; it is widely used in construction, advertising display boards, mounting board, screen printing, carving, etc.

PVC foam board / sheet / pallet is the best material in block making industry as the carrier of the green blocks, it has the advantages of highest strength with smooth surface, moisture proof and heat-resistant, it can maintain stable performance under high temperature. Waterproof, anticorrosive, metabolic and recyclable, moisture resistant, lightweight.

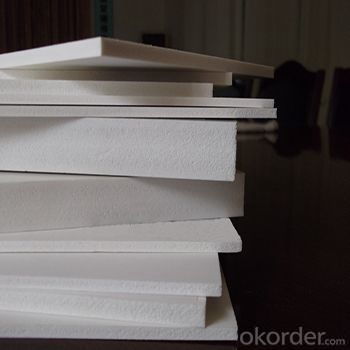

Specification

Regular size: 1220*2440mm, 1560*3050mm, 2050*3050mm

Thickness:1-33mm

Density:0.35-0.

Product Features

(1) Light weight, waterproof, fire retardant and self-extinguishing

(2) Sound insulation, heat insulation, noise absorption, heat preservation and anti-corrosion.

(3) Tough, rigid with a high impact strength, not easy to age and can keep its color for long

(4) Easy to clean and maintain.

(5) Environmental- friendly green and lead-free.

Product Application

(1)Advertising: exhibition display, digital printing, silk screen printing, computer lettering, sign board, light box, etc.

(2)Construction: office and bathroom cabinets, inner and outer decorate panel, commercial decorating shelf, room separating

(3)Transportation: steamboat, airplane, bus, train carriage, roof and carriage inner layer and other industry.

Pictures:

Why choose us?

1.We are large manufacturer with 20 years professional experience

2.We have passed ISO9001 and the standard attestation SGS.

3.We have special team work for after sales7*24 to help you solve any kind of problem

- Q: On multiple care sheets I have read that Corn Snakes and Ball Pythons and other Snakes like that could live in Transparent plastic storage Boxes but how would you use heat mats and humidifiers.I also went to an animal rescue and they said,you could keep them in boxes long term and they have rows of these with snakes in and they were at Gullivers World with a species of a Young Boa Constrictor that was about 4ft long and in an approximate size box of 2ft x 1 1/2 x 1/2ft.

- Aren't you the equal character who mentioned your vet stated that snakes want bubblers and lovers? Simply seeing that anybody has long gone to veterinary school does now not make them a reptile informed, and your vet is an effective instance of this. A snake does no longer need an enclosure longer than them, nor do they must be able to look outside. Even in the wild, they discover a tight little situation to hide and stay curled up, now not stretched out. A plastic bin is a lot better than an aquarium with a reveal lid at keeping warmth and humidity. They may be additionally more cost effective and simpler to wash. The one advantage of a tumbler aquarium is it makes a greater display, which couldn't topic to the snake one bit. If I were you, i'd give up being attentive to your vet and i'd give up accusing people of animal cruelty who're more proficient than you and who take higher care of their animals than you. But go ahead and switch in some breeders for animal cruelty so that after animal manipulate says their snakes are being effectively cared for, they can sue you for harassment.

- Q: Are plastic sheets resistant to humidity?

- Yes, plastic sheets are generally resistant to humidity as they do not absorb water and are not affected by moisture in the environment.

- Q: what is shrinkage for pp+15%epdm plastic can i have the data sheet?

- You can sign in and get the data sheet at the link below.:

- Q: making a hard plastic cover for my poker table. Home depot wants like 120 bucks for a sheet!! Anyone know of anywhere cheaper?

- try glass its cheaper

- Q: Can plastic sheets be bent or shaped?

- Yes, plastic sheets can be bent or shaped using various methods such as heat forming, vacuum forming, or cold bending techniques, depending on the type and thickness of the plastic.

- Q: What is the be plastic thing called?

- sterile equipment tape (at least that's what my dentist uses). It comes on a roll of tape (just like regular tape) and sort of looks like cellophane.

- Q: how does the cloth became a positive charge when it is rub by a plastic sheet?

- it just dos why so worried

- Q: I have a house in an area (southern Ontario) that is subject to wind-storms. I want to enclose my side porch in plastic so that I can smoke there - I just had a baby and can't smoke inside anymore. I put up 5 mm plastic with staples and strapping wood held up with finishing nails, but in the first wind-storm most of it came down. Would tarps work better? I can't afford to do it in properly with lattice and plywood right now, although that is my ultimate goal. Also I am alone here with my baby, my husband is a long-hauler and I need to be able to do this myself. I can operate a nail gun, a skil-saw, a staplegun. Please advise!

- Enclosing A Porch

- Q: And does this improve stereo sound quality...???

- moisture doesnt care how thick your plastic is. and no it wont make MUCH of a sound difference. windows make more noise usually.. unless u have shotgun holes thru your door - i doubt it. just make sure the plastic is sealed all over.. moisture on the inside or outside? any cheap plastic will do - heck, even garbage bags.. theyre not exposed to sunlight so wont break down from UV.. just tape em airtight allover. use (non chinese) duct tape - its good. u can tear it in half size strips easily too/

- Q: How do plastic sheets compare to glass?

- Plastic sheets and glass have different properties and uses, making them suitable for various applications. While glass is more rigid, transparent, and offers better optical clarity, plastic sheets are lighter, more flexible, and have greater impact resistance. Additionally, plastic sheets are easier to shape and less expensive than glass. The choice between plastic sheets and glass depends on specific requirements such as durability, transparency, weight, and cost.

Send your message to us

PVC free foam board mould extrusion die head Plastic Marble machinery

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords