PVC Foam Sheet and PVC Foam Panel Sheets for Cladding

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 ft

- Supply Capability:

- 500000 ft/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PVC Foam Sheet Introduction:

PVC Foam Sheet, a kind of high-tech product, is produced by special machinery and technology processing. The main material PVC resin can be foamed and extruded into a special sheet with many advantages, such as glossy or matt surface, waterproof, flame-resistant, UV stable, sound and heat insulation, anti-chemical corrosion, etc.

Kingstar PVC Foam sheet is manufactured by the equipment imported from well-known Italian Bausano Group and Austria Cincinnati Company. We, with more than 15 years' processing experience, have invented several formulas to ensure every piece of sheet could be perfectly used.

Features:

1. Light weight, easy and convenient to storage, transportation and use

2. It could be drilled, sawed, nailed, turned, glued, bended, printed, oiled, etc

3. Uniform fine & close cell structure

4. Hygienic, Rigidity, Durable

5. Perfect chemical corrosion resistance, good resistance to UV & weathering

6. Fire retardant and self extinguishing

7. Moisture-resistant, mildew proof, rot proof, low water absorption

8. Non-deformation, color fastness for a very long time

9. Sound insulation, sound absorption, heat insulation and heat preservation

10. Easily to put protective film on one or two sides

11. Smooth surface and suitable for silk-screen printing, laser engraving (must clean the surface before printing)

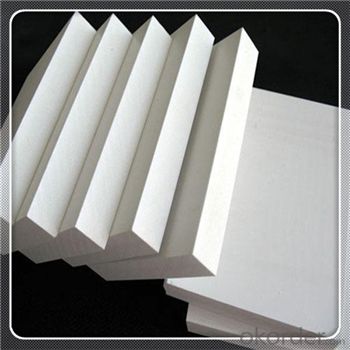

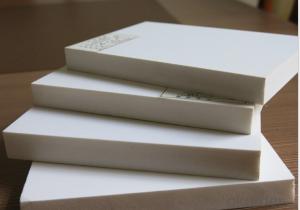

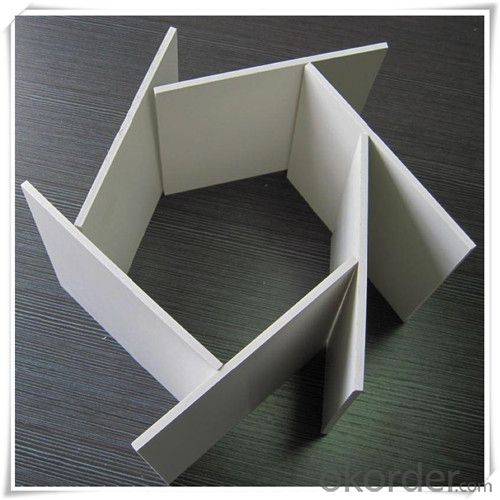

PVC Foam Sheet Details show:

Name | Density(g/cm3)±0.02 | width and length(mm) | Thickness(mm)±0.2 | Color |

PVC Foam Board | 0.8 | 1220*2440 | 1~25 | white,red, yellow, blue, green, gray, black |

0.6 | 2~25 | |||

0.5 | 2~25 | |||

0.8 | 1560*3050 | 1~10 | ||

0.6 | 2~10 | |||

0.7 | 2050*3050 | 1~10 | ||

pvc rigid sheet | 1.36-1.45 | 1220*2440 | 0.23-1.8 | |

2-5.8 |

Applications:

1. Advertising Signs, billboards, displays, exhibition stands

2. Screen printing, laser engraving

3. Thermoformed parts

4. Architecture, indoor and outdoor decoration

5. Furniture, kitchen & bathroom cabinet

6. Walls & partitions, wall cladding

7. Poolside furniture, swimming pool floor planking

8. Board for Chemical industry and laboratory equipment

9. Interior scaleboard for boat & ship, vehicle, train

Pictures:

FAQ:

Q: What's the PVC Foam Sheet Processing performance?

A: 1, plastic coating, membrance-stuck and printing

2, with the usual equipment and tools, it can be processed again.

3, welding and bonding

4, cutting and sawing

5, bending when heated-up, thermal forming

6, hole-drilling, Channeling and die cutting

- Q: Cabinet door environmental protection grade how to divide

- Cabinet door of the substrate if it is a density board, then its highest environmental rating is E1 level, and like the double-sided surface of this substrate is the particle board can reach the highest standards of Japan JIS four standard environmental standards

- Q: There are children at home, very concerned about this problem. Thank you, you have bought, the brand called Sharon Dick this is quite good.

- Solid wood furniture, formaldehyde content than the number of low-grade furniture, no specific indicators, generally much lower. General real wood furniture are E0 level, the main impact of solid wood furniture is part of the formaldehyde content of the paint. Formaldehyde mainly from the glue, adhesives, paint and other processing to the part. Why is the flat furniture containing formaldehyde is relatively high, mainly due to plate furniture, sheet metal forming process using a large number of adhesives, sheet molding methods, different materials, formaldehyde content is inconsistent. E0 does not represent 0 formaldehyde, but the content of a level, generally this level of formaldehyde content is not affected. Brand and formaldehyde content is not related, this depends on the indicators. Now many families to buy solid wood furniture, cabinets and other colors used, that is, not painted, the texture of the logs is also very beautiful. This practice is the use of children's room furniture.

- Q: Are there any plates of E0 grade?

- There are ah, there are E0 eco-board, blockboard also E0 level!

- Q: Round round plate, environmental protection plate top ten brands

- Now the decoration is environmentally friendly sheet, the top ten brands are: round and round, Fuqing, Moganshan, Millennium boat, bunny, etc.

- Q: Qianshan Wood Malacca plate how much money a piece

- Normal more than 200 to 300 have, too cheap do not easily believe that is likely to be fake, decoration with the plate can not careless, to prevent the use of poor quality sheet, affecting health, choose authentic, in order to simply identify genuine, each There are anti-counterfeit labels on the plate, you can go to the official website query verification.

- Q: Always said that the plate is very complex, think about learning a little professional knowledge

- Can be distinguished by the following steps and methods: First is "see", but also to see the focus. Good plate surface smooth and smooth, the edge of the board is very clear. As well as the packaging on the plate is clear, the above name, address, grade, specifications and other information are complete, not clear, incomplete information or more attention to the plate, and may be added to the color of the plate. Two smell, because the legendary formaldehyde is released from the plate, will directly affect people's health. Good plate not only good choice of materials, but also for the adhesive glue is environmentally friendly, even if the number of more stacked together, it will not emit a very pungent taste. If the choice of a plate placed in the home there is a very obvious pungent chemical smell, it should be noted. ?Three saws, before the purchase can be a small sample to the business, and then cut it to see its inner core, a good plate section level is very clear, because it is a layer of paste a very tight, very good convergence, and those miscellaneous Wood stitching the poor quality of the plate core is not dense, must not buy. Four test, through the relevant identification agencies, with professional tools and related technical means to identify the plate to determine the quality of good or bad, this method is more professional and accurate. Plate material is also an important factor is the moisture content, the general moisture content of the plate should be less than 16%, if too high that is not good, may be a while will be mildew or deformation.

- Q: Guangzhou red cotton plate and ordinary moisture board What is the difference

- A moisture-proof one is not moisture it

- Q: What are the classification of timber for construction?

- uilding timber is divided into: logs, square materials, sheet, glue material. Good understanding of logs. Square wood is machined into rectangular or square, and the aspect ratio is less than 3. Thickness ratio greater than or equal to 3 for the plate. Plywood is a man-made material, is the use of various materials using the corresponding production process manufacturing. Logs, square wood is mainly used for columns, beams, roof trusses and so on. Plate, plastic material used for wall, ceiling and other decorative parts.

- Q: What are the different characteristics of the plate?

- Lead plate can play the effect of radiation, the general plate does not have this ability. Understand the plate, you can go to China plate trading network to see, more types of plates.

- Q: What kind of sheet is it better to do a desk!

- Now the desk, if not often need to use tools to characterize things, most generally do not use glass platen or table, because it is in the winter "cold feeling " not comfortable "general now desktop, with polyamine It is best to use a glassy material that can be made of "high light" (high brightness) or "matte" (low abrasive, low brightness) , It is recommended to use "steel flat glass" to do the desktop, this "compressive strength " much better.

Send your message to us

PVC Foam Sheet and PVC Foam Panel Sheets for Cladding

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 ft

- Supply Capability:

- 500000 ft/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords