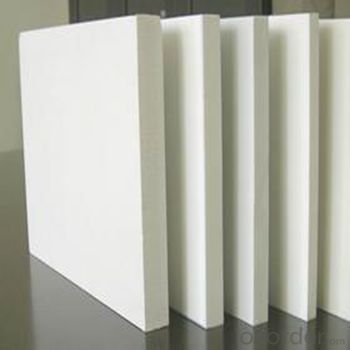

Plastic Sheets - PVC Cabinet Foam Sheet / PVC Foam Panel Sheets for Cladding

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

About us:

We are packaging foam board manufacturer, packaging foam board is becoming the substitution of wood in many fields such as AD and Decoration. We have our own factory, transportation system, overseas warehouse, industrial park.As a professional manufacturer. It made through foaming and pressing into shape with additives. The main material is PVC. So it covers not only features of woodplast, but also very light and can be printed, engraved easily.

Product Uses

1 mm- 5 mm: suitable for advertising supplies, electronic instrument, packaging

15 mm -20 mm: suitable for furniture

10 mm -20 mm: suitable for bath cabinet, cabinets

5 mm- 20 mm: exhibition board, indoor and outdoor decorative plate (different customers have different requirements)

3 mm coated :bus interior ceiling

Features:

1, light weight,good tenacity, high rigidity

2, fireproof and flame retardant

3, good insulation

4, no sopping, no deformation

5, easily to processed

6, good plasticity, being an excellent thermoform material

7, sub-light surface and elegant vision

8, anti-chemical corrosion

9, suitable to silk screen printing

10, with imported dyes, unfading and anti-aging

Market outlook:

PVC foam board with these advantages, wide application field, the current is very widely used in the developed countries, and in China's development is relatively slow. As the country for energy conservation and environmental protection requirements of the building materials and other materials and China's timber resources increasingly scarce, PVC foam board will usher in rapid development.

Product Application

Advertisement: printing in silk screen,sculp, setting-cut board, lamp box, etc;

Building upholster: decording indoor and outdoor, business decorative, separate the house;

Furniture process: stationery of indoor and office, kitchen and toilet;

Manufacture of car and ship: upholster in car, ship and plane;

Industry manufacture: project of antisepsis and environment protection,refrigeratory, moulding-hot part

Products Pictures

Pictures of Factory

- Q: Can plastic sheets be used for protective barriers in retail settings?

- Yes, plastic sheets can be used effectively as protective barriers in retail settings. They offer a transparent and durable solution that helps to create a physical barrier between the customers and staff, minimizing the risk of transmission of germs or viruses. Plastic sheets can be easily installed as sneeze guards or checkout dividers, providing an added layer of protection for both employees and customers.

- Q: Do plastic sheets have any limitations or disadvantages?

- Yes, plastic sheets have limitations and disadvantages. They are not as durable as other materials such as metal or glass, which means they can easily crack, break, or warp over time. Additionally, plastic sheets are less heat resistant, making them unsuitable for applications where high temperatures are involved. They can also be prone to scratching and can accumulate static electricity. Moreover, certain types of plastic sheets may release harmful chemicals when exposed to certain conditions, posing health and environmental risks.

- Q: Can plastic sheets be used for horticultural purposes?

- Yes, plastic sheets can be used for horticultural purposes. They are commonly used as a protective covering for plants, creating a greenhouse-like environment that helps retain heat and moisture, promoting faster growth and protecting plants from harsh weather conditions. Plastic sheets can also be used for mulching, weed control, and creating temporary plant shelters.

- Q: I saw this on a solar panel website one time but am now unable to locate. It's a thin sheet of what appears to be plastic but it isn't clear... it's more opaque than anything. What the site claimed was that by shining the sun through this plastic (like shining the sun through a magnifying glass) you can intensify to some (great) degree onto a particular area. Anyone ever heard of it? Does this type of material exist? Is it a scam? Any information appreciate.

- sounds like a fresnel lense

- Q: I've been working with a lot of humanitarian help lately, and have noticed that most mediocre plastic sheeting (tarpaulin) is blue whereas the good stuff is white or white on one side and black on the other. Why is most plastic sheeting blue? Is there any particular reason for this choice in color?

- Interesting! Rope seems to be blue too.

- Q: Can plastic sheets be used for flooring?

- Yes, plastic sheets can be used for flooring. They are often used as temporary or low-budget flooring options in areas such as garages, basements, or workshops. However, it's important to note that plastic sheets may not be as durable or aesthetically pleasing as traditional flooring materials like hardwood or tiles.

- Q: PVC how dirty is the plastic board? Can it be cleaned soon?

- Wash with toothpaste and toothbrushBecause it is not a big object, you can simply brush with toothpaste and then wipe it gently until you wipe it. This adds flavor to the purse.

- Q: I have a Brother HL-5140 and I've search the internet, but cannot find out if this printer will print on the overhead projection paper or if it will melt the plastic sheets. Can anyone with this printer tell me? Or can someone tell me what wording to look for on a list of printer specs that will tell me? Thanks!

- This Site Might Help You. RE: Can my printer print on overhead projection sheets? I have a Brother HL-5140 and I've search the internet, but cannot find out if this printer will print on the overhead projection paper or if it will melt the plastic sheets. Can anyone with this printer tell me? Or can someone tell me what wording to look for on a list of printer...

- Q: How do plastic sheets compare to glass?

- Plastic sheets are generally more flexible, lightweight, and shatterproof compared to glass. However, glass offers superior clarity, higher resistance to scratches, and better heat resistance. The choice between plastic sheets and glass depends on the specific application and desired properties.

- Q: Should I spread plastic sheets and newspapers across the floor in case one of us has an accident?

- If you were vinyl, you wouldn't need to, understand now?

Send your message to us

Plastic Sheets - PVC Cabinet Foam Sheet / PVC Foam Panel Sheets for Cladding

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords