Plastic Sheets - PVC Foam Board Signs/Custom UV Printing 1mm-5mm PVC Board Directly

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 litre

- Supply Capability:

- 10000 litre/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Introduction

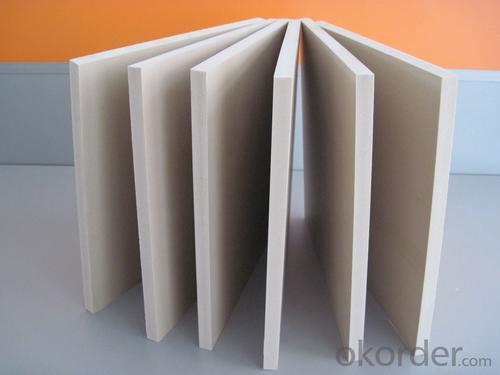

PVC foam board is made from polyvinyl chloride, with flat plate surface, it is widely used in construction, advertising display boards, mounting board, screen printing, carving, etc.

PVC foam board / sheet / pallet is the best material in block making industry as the carrier of the green blocks, it has the advantages of highest strength with smooth surface, moisture proof and heat-resistant, it can maintain stable performance under high temperature. Waterproof, anti-corrosive metabolism and recyclable,moisture resistant,lightweight.

2. Features

(1).Environmental and non-toxic material

(2).Waterproof and fireproof

(3).Easy maintenance

(4).Kinds of sizes, attractive appearance, reasonable price

(5).Impact Resistant

(6).Light in weight and easy to install can save a lot of time and man power cost.

3. Application

(1) Advertising: exhibition display, digital printing, silk screen printing, computer lettering,sign board, light box,etc.

(2) Construction: office and bathroom cabinets, inner and outer decorate panel,commercial decorating shelf, room separating

(3) Transportation: steamboat, airplane, bus, train carriage, roof and carriage inner layered other industry.

4.Detailed parameter list

1 | Product | PVC Foam board/sheet/panel |

2 | Standard size | 1220mm × 2440mm ; 1560mm × 3050mm ; 2050mm × 3050mm and so on |

3 | Thickness | 1~ 30mm |

4 | Density | 0.4~ 0.8g /cm 3 |

5 | Brand | CMAX |

6 | Color | White, Black, Red, Green, Pink, Grey, Blue, Yellow, etc |

7 | Executive standard | QB/T 2463.1-1999 |

8 | Certificate | SGS |

5.Characteristics

(1) Light weight

(2) High strength

(3) Easily cleaned

(4) Easily fabricated

(5) Outstanding print-ability

(6) Uniform fine close cell structure

(7) Good resistance to light and weathering

(8) Low flammability

6. FAQ

(1). Sample: Can I get samples?

Yes, samples are available and can be provided free of charge, customer only need to pay for the shipping cost.

(2). Is OEM or Custom Order available?

Yes, we can do custom order according to drawings or photos or samples.

(3). Which Payment Terms?

Ali Trade Assurance, T/T(Telegraphic Transfer), West Union, L/C etc.

(4). Lead Time: How soon we can get the shipment?

Usually, it's within 7-15 working days after receiving payment.

7.Advantages

1. we have our owned PVC foam sheet factory located , China's most popular pvc sheet production area, which make sure the production ability and products high quality.

2. our office located in Beijing , the capital of china , it makes us to keep in touch with buyers timely and very convenient for business talking in our office

3. our overall different department makes us the high standard of working efficiency. such as our solid financial department, sales department, documents department and logistic department .

- Q: should I cut out and put one of those plastic overhead sheets as a screen protector or just buy one?

- BUY ONE for as little as they cost best safe then sorry

- Q: What are the common applications of plastic sheets?

- Plastic sheets have a wide range of applications, including use in packaging materials, construction projects, automotive industry, signage and advertising, medical and healthcare products, electrical and electronics components, and even in arts and crafts.

- Q: Hi guys, I'm about to tile my bathtub surround and have some questions regarding moisture barriers. I already have the 1/2 durock cement board and 6 mil plastic sheeting. Before I put up the plastic sheeting on the studs, I wanted to double check to see what people thought was a better moisture barrier... Redgard painted directly onto the cement board or the 6 mil heavy duty plastic sheeting attached to the studs. If you pick one over the other, can you tell me why? Is there a difference in how well each one will protect from long term moisture problems? It would be nice to hear the pros/cons to Redgard vs the plastic sheeting.I'm debating whether or not I should just go buy some Redgard and leave my plastic sheeting for another purpose. But if they both offer the same long term protection, then I'm happy just sticking with my plastic sheeting since it will save me a trip to the store and I am more familiar with that as a moisture barrier.

- I've done a whole lot of this work over the years. Redgard is the best product I've ever seen for a moister barrier It's the standard for shower / tub surrounds. It's easy to use and will protect for a lifetime. Hang your cement board with the proper screws. Tape the seems and corners with fiberglass tape. Paint the redgard over the entire surface. Let dry; you know it's dry because it will turn from pink to red in color. Add another coat (or two) over the seems and corners to make sure the seems are sealed. Let dry. Install your tile or stone using thin set mixed with polymers. When you grout make sure to mix your grout with polymers. I know some guys who will use thin set to mud the seems before taping. This works well if you have some bigger gaps, but redgard is pretty thick stuff, like pudding. This type of installation will insure no water gets back behind your walls and will last a lifetime. Plastic has the issue of nail / screw holes, trapping water, and condensation. Redgard dose not because it is a moister barrier that you can lay tile directly on. There are other options and systems, but they tend to be more costly and harder to install. On a side note: I find redgard dose not apply well with a roller. It's very thick. I like to use a large brush. Plus a brush helps insure a good thick coat.

- Q: So I went to staples and had them laminate like 8 papers I HAVE to have laminated by tomorrow.... And I picked them up, came home, and they were literally my papers stuck between 2 plastic sheets. I can peel it easily and it is not sticking at all. Am I supposed to do something or did they mess up and forget something???? Please help!!!!

- It sounds like they messed up. My guess is that the machine was not hot enough to allow the laminate sheeting to bond. Yes, you should call them and go back. Laminating IS two plastic sheets with a paper between. However, when the machine is very hot, the plastic softens and bonds. Did you trim the papers? You should always leave a narrow edge of plastic around the edges, perhaps a quarter inch. If you trim it exactly against the paper, there is nothing on the edge to seal and bond. If they did the trimming, then check the edging. If there is a quarter edge beyond the paper and it is separating, then take it back. That could be a machine not hot enough. Take your receipt.

- Q: Are plastic sheets resistant to discoloration from cleaning chemicals?

- Yes, plastic sheets are generally resistant to discoloration from cleaning chemicals.

- Q: im trying to make a plexiglass longboard skateboard out of plexiglass

- I would recommend using a polycarbonate like Lexan or Hyzod instead of acrylic resin products like Plexiglas. They are considerably stronger, yet easier to work with. I think a 3/4 inch thickness would be lots if you went with Lexan, but at 4 feet long, any plastic sheet is going to be bouncy (Plexi will snap). You might have to edge it with something rigid to fix that. Usually anything over 1/4 inch (~6mm) is special order, but you never know, a local sign shop or glass shop might have some cutoff for you.

- Q: I've been working with a lot of humanitarian help lately, and have noticed that most mediocre plastic sheeting (tarpaulin) is blue whereas the good stuff is white or white on one side and black on the other. Why is most plastic sheeting blue? Is there any particular reason for this choice in color?

- 1) Blue is a color that contrasts most other natural colors in it's surroundings such as green grass and brown dirt, and therefore is found easily for cleanup. 2) Out of the colors they could use, blue is the cheapest to produce. Black, and surprisingly even white, costs more than blue die. This is because most raw plastic is a gray or multiple colors, so it takes more bleach to make it white than it does to just color it blue. Plus the materials necessary to create blue die are cheaper than most other colors. 3) Blue does not absorb as much heat as some other colors would, and therefore will keep it's integrity longer.

- Q: Can plastic sheets be used for skylight replacements?

- Yes, plastic sheets can be used as a replacement for skylights. They are lightweight, durable, and usually less expensive than traditional glass skylights. However, it's important to ensure that the specific type of plastic sheet used is suitable for skylight applications and provides adequate insulation and UV protection. Additionally, regular maintenance and cleaning may be required to prevent yellowing or deterioration over time.

- Q: Why does wrapping a house with plastic sheeting, typically Tyvek, reduce advective heat loss?

- Tyvek okorder / ...

- Q: Can the toilet be covered with plastic buckles?

- In the past two years, the integration of new and beautiful, more people are used, usually with a special set of lamps and lanterns, but the material is not waterproof, the price is more expensive. If it is used before the gusset plate is the waterproof effect is good, the price is cheaper, with common bathroom bath explosion-proof lamp is good, the price is down to save a lot of money than integrated.

Send your message to us

Plastic Sheets - PVC Foam Board Signs/Custom UV Printing 1mm-5mm PVC Board Directly

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 litre

- Supply Capability:

- 10000 litre/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords