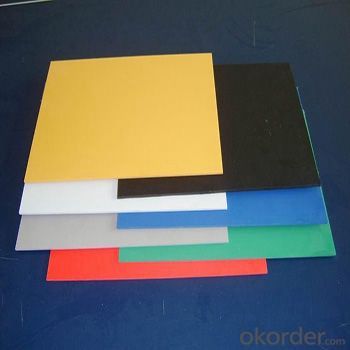

PVC Foam Board and Sheet - Plastic Sheets with Specifications

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

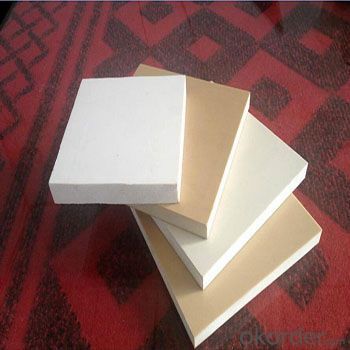

Specifications:

1 width: 1220mm,

2 Length: 2440mm or as per your requirement,

3 Thickness: From 1mm to 30mm

4 Density: from 0.45 to 0.9

Features:

1, light weight,good tenacity, high rigidity

2, fireproof and flame retardant

3, good insulation

4, no sopping, no deformation

5, easily to processed

6, good plasticity, being an excellent thermoform material

7, sub-light surface and elegant vision

8, anti-chemical corrosion

9, suitable to silk screen printing

10, with imported dyes, unfading and anti-aging

Good performance:

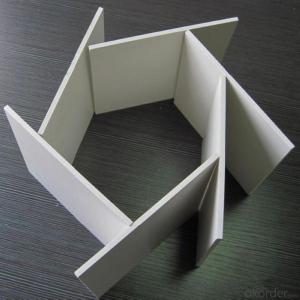

1, plastic coating, membrance-stuck and printing

2, with the usual equipment and tools, it can be processed again.

3, welding and bonding

4, cutting and sawing

5, bending when heated-up, thermal forming

6, hole-drilling, Channeling and die cutting

7, nail, wrest and rivet

Parameter

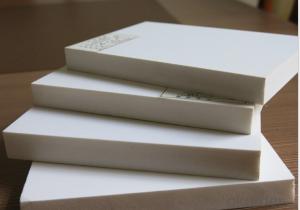

| Products Name | pvc foam board |

| Thickness | 1~33mm thickness |

| Regular Size | 1220x2440mm (4’x8’) |

| Main Material | PVC powder |

| Surface Treatment | As per your request |

| Color | White,black |

| Certificate | SGS,3C,RoHs, ISO |

| Service | OEM |

| MOQ | 1*20GP |

| Payment | 30% deposit, 70% balance before shipment. T/T W/U M/G |

| Delivery Time | 7-30 days. |

| Packing | Carton box or wooden pallet packing. |

| production capability | 10000 tons per month. |

- Q: Are plastic sheets resistant to warping due to temperature fluctuations?

- Yes, plastic sheets are generally resistant to warping due to temperature fluctuations. However, the degree of resistance may vary depending on the type and quality of the plastic used.

- Q: Are plastic sheets resistant to cracking or splitting?

- Yes, plastic sheets are generally resistant to cracking or splitting.

- Q: Im looking for a cheap sheet of plastic about 8 .5 feet long and 17.5 inches wide. I need it to be slippery and and make sure it wont scratch my snowboard. I live in the chicagoland area and i was wondering where i could buy a cheap sheet of plastic. i asked my local ice arena and they told me they dont have any puckboard. i know about hdpe but its to expensive. i dont wanna ship for it and id like to buy it at a plastic warehouse or a home improvement store. thanks

- ok im not really sure what your talking about but maybe try two plastic table cloths put together or new not used garbage bags?

- Q: A large horizontal flat sheet of insulating plastic (near the earth's surface) carries a total charge +22MC distributed over the area of the sheet (1.1m^2). A dust mote carries charge +3.5mc and has a mass of 2.2x10^-4 kg. What is the acceleration when it is just above the sheet of charge? Don't neglect gravity.

- The force exerted by the sheet is F=E*q where E=6/(2*e0) 6 charge density in this case 6=q/A=20*10powered6 C/m2 e0=8,85*10powered12 C2/(N*m2) (n2 means n powered 2) a*m+E*q=m*g a=(m*g - q*6/(2*e0))/m if g=9,8 m/s2 then a=9,79998 m/s2

- Q: I am attempting to make a model of a building in construction. I need the plastic to be hard and color means nothing. I am making the beams and columns for the building.

- Use a plastic coffee container. If you cut the strips vertical, you could roll them into a column. If you want a square column, cut narrower strips and glue four of them together. If a taller column is needed, you can overlay one on top of the other.

- Q: I'm trying to learn Gauss's law and I'm having trouble with these two questions.1. Consider a long cylindrical charge distribution of radius R = 17 cm with a uniform charge density of ρ = 17 C/m3. Find the electric field at a distance r = 35 cm from the axis. I know E= 2k_e*(lamda/r), but the question gave rho, which is confusing me.2. A 12 g piece of Styrofoam carries a net charge of -9.1 ?C and floats above the center of a large horizontal sheet of plastic that has a uniform charge density on its surface. What is the charge per unit area on the plastic sheet? I got to the point where I had the charge density = -mg(epsilon_0)/q, but apparently that is not the correct answer, and I don't know where to go from here.Any help is appreciated. Thanks :)

- 1. Since it's a volume charge distribution , charge = rho*volume . Take a cylindrical gaussian surface of length 'h' at distance r from the axis . Now , E*2pie*r*h = q/epsilon = rho*pie*r^2*h/epsilon . which gives E = rho*r/2epsilon . 2. The electric field due to non-conducting sheet is sigma/2epsilon which gives your answer sigma = -2mg(epsilon)/q . The electric field due to conducting plate is sigma/epsilon since it has two effective surfaces with charge . You must have got confused there . Hope this helps .

- Q: i have to figure out the price of ONE overheadd projector plastic sheet for school, so how many of these plastic sheets are in a pack ??? please help !!

- Staples sells them in packs of 100 for the write on kind for $37 The kind you can use in a printer in packs of 50 for $40 So I guess the write on kind = 37 cents each ink jet kind = 80 cents each

- Q: How do plastic sheets handle bending without breaking?

- Plastic sheets are able to handle bending without breaking mainly due to their flexibility and resilience. The molecular structure of plastics allows them to deform under stress and return to their original shape once the stress is relieved. Additionally, the presence of additives and plasticizers in the material can enhance its flexibility, making it more resistant to breaking when bent.

- Q: What are the disadvantages of using plastic sheets?

- One major disadvantage of using plastic sheets is their negative impact on the environment. Plastic is non-biodegradable and takes hundreds of years to decompose, contributing to pollution and litter. Additionally, the production of plastic sheets involves the extraction and processing of fossil fuels, contributing to climate change and depletion of natural resources. Plastic sheets are also prone to tearing and damage, making them less durable compared to other materials.

- Q: What are my options? What's the name of these type of plastics?Id like to buy in bulk, raw sizes to get the lowest price possible..

- any big office supply store.

Send your message to us

PVC Foam Board and Sheet - Plastic Sheets with Specifications

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords