Eco Friendly PVC Electrical Tape Packed with Bags and Carton

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of PVC Electrical Tape Packed with Bags and Carton

A thin premium grade plasticized PVC film coated with an aggressive rubber based adhesive with good characteristics. It is highly conformable and unaffected by most chemicals and moisture

Application of PVC Electrical Tape Packed with Bags and Carton

Electric insulation below 600V; Insulating wrapping of electric wires and cables; Marking of electric wires and cables; Can be used indoors and out door

Available Size of PVC Electrical Tape Packed with Bags and Carton

Paper Core ID: 76mm; 56mm; 38mm; 32mm

Jumbo Roll size: 1250mm x 33m

Cut roll size: 19mm x 10m; 19mm x 20m or as per customer's requirement

Cut rolls: Nine rolls in one plastic bag, placed in cartons, with or without pallet

Packing of PVC Electrical Tape Packed with Bags and Carton

Jumbo rolls & log rolls: Packed with kraft paper and stretch wrap film, with or without pallet

Cut rolls: Shrink package, placed in cartons, with or without pallet

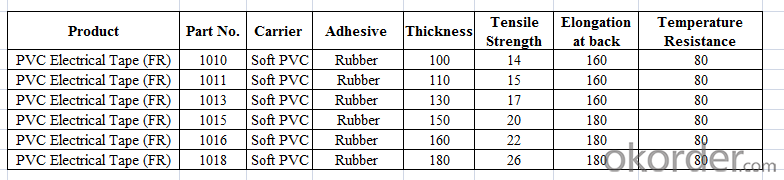

Technical Data of PVC Electrical Tape Packed with Bags and Carton

Product Show of PVC Electrical Tape Packed with Bags and Carton

FAQ: What are your company advantages?

Company Advantages:

1. Stable financial status and sound reputation as a state invested corporation under the direct administration of the State Council of PRC;

2. CNBM’s worldwide influence as one of the 500 global fortunes specializing in building materials including adhesive tapes;

3. More than a decade’s exporting experience and technology in adhesive tape industry;

4. Preferential shipping channels, with a separate team dealing with shipping.

- Q: Does packaging tape have a specific weight capacity?

- Packaging tape indeed possesses a specific weight capacity. The weight capacity of packaging tape relies on its thickness, width, and overall quality. Typically, packaging tapes are engineered to effectively seal boxes and packages, with their weight capacity determined by their adhesive strength and resilience. The majority of standard packaging tapes can handle a weight capacity ranging from approximately 20 to 30 pounds. Nonetheless, there are heavy-duty packaging tapes available that can manage weights of 50 pounds or more. It is crucial to take into account the weight of the package or box that requires sealing and opt for a packaging tape that can accommodate the precise weight capacity in order to ensure a secure and dependable seal.

- Q: Is packaging tape suitable for sealing heavy boxes?

- Yes, packaging tape is suitable for sealing heavy boxes. Packaging tape is designed to provide a strong and secure seal for boxes of various sizes and weights. It is made from durable materials such as polypropylene or reinforced paper, which adds strength to the tape and ensures that it can handle the weight and pressure of heavy boxes. Additionally, packaging tape usually has a strong adhesive that bonds well with cardboard surfaces, ensuring a tight seal that can withstand the rigors of transportation and handling. However, it is recommended to use multiple strips of tape to reinforce the seal on heavy boxes for added security.

- Q: How does packaging tape perform on oily or greasy surfaces?

- Packaging tape typically struggles to perform well on surfaces that are oily or greasy. The adhesive on packaging tape is specifically designed to stick to surfaces that are clean and dry. Therefore, when applied to surfaces that are oily or greasy, the tape may have difficulty sticking securely. The presence of oil or grease acts as a barrier, preventing the adhesive from effectively bonding with the surface. Consequently, there is a greater likelihood of the tape peeling or coming loose. To ensure proper adhesion on surfaces that are oily or greasy, it is advisable to clean and degrease the surface thoroughly before applying packaging tape. Using a degreasing agent or detergent can assist in eliminating the oil or grease, thereby enabling the tape to adhere more effectively. In addition, opting for a high-quality packaging tape that possesses a strong adhesive can also help overcome the challenges posed by oily or greasy surfaces.

- Q: Can packaging tape be used for sealing retail or product packaging?

- Certainly, retail or product packaging can be effectively sealed using packaging tape. Specifically designed for securely sealing boxes and packages, packaging tape offers a durable seal. Its usage is widespread across various industries, including retail, e-commerce, and product packaging. Made from robust adhesive material, packaging tape guarantees the package remains sealed throughout transportation and handling. Its ease of use allows for quick and efficient application. Moreover, packaging tape comes in a range of sizes and strengths, enabling it to meet diverse requirements for different types of retail or product packaging. In conclusion, packaging tape proves to be a dependable and efficient choice for sealing retail or product packaging.

- Q: Is packaging tape safe to use on plastic outdoor furniture?

- Packaging tape is generally considered safe for use on plastic outdoor furniture. It is designed to adhere to different surfaces, including plastic. However, before using packaging tape on your outdoor furniture, it is important to take several factors into account. First and foremost, ensure that the plastic surface is clean and free of dirt or debris. This will enhance the tape's adhesion and prevent any harm to the furniture. Additionally, apply the tape evenly and firmly to avoid any peeling or lifting issues. It is crucial to remember that packaging tape is not specifically created for long-term outdoor use. Although it can be effective in temporarily securing items or protecting surfaces, it may not endure prolonged exposure to severe weather conditions or UV rays. Over time, the tape may deteriorate or leave sticky residue on the plastic furniture. If you require a more durable and weather-resistant solution, it is advisable to utilize specific outdoor adhesives or tapes specifically designed for this purpose. These products are typically made with materials that can withstand outdoor elements and are better suited for long-term use on plastic outdoor furniture.

- Q: Can packaging tape be used for sealing ceramic items?

- Yes, packaging tape can be used for sealing ceramic items. Packaging tape is designed to be strong and durable, making it suitable for securing and sealing various materials, including ceramics. However, it is important to note that packaging tape may not provide the same level of protection as specialized ceramic sealants or adhesives. If you are looking for a more secure and long-lasting seal, it is recommended to use a ceramic-specific adhesive or sealant that is designed to withstand the unique properties of ceramics, such as temperature changes or moisture exposure.

- Q: Can packaging tape be used for sealing packages with fragile artwork or sculptures?

- Indeed, one can utilize packaging tape for the purpose of sealing packages containing delicate artwork or sculptures. Nevertheless, it is crucial to exercise caution in selecting the appropriate variant of packaging tape to guarantee the safeguarding of the artwork. In general, it is highly recommended to opt for a top-notch, robust packaging tape that has been explicitly crafted for the purpose of shipping and handling fragile or delicate items. These varieties of tape often possess added reinforcement through the inclusion of fibers or augmented adhesive strength, thereby ensuring a secure seal and averting any potential harm during transportation. Furthermore, it is advisable to employ suitable cushioning materials such as bubble wrap or foam padding to provide adequate protection for the artwork housed within the package.

- Q: Can packaging tape be used for sealing electronics or appliances?

- It is not advisable to use packaging tape for sealing electronics or appliances. Although packaging tape is created to effectively seal cardboard boxes and packages, it is not suitable for sealing electronics or appliances due to several reasons. First and foremost, packaging tape does not offer sufficient protection against moisture or dust, which can be detrimental to electronic components. In order to prevent any damage or corrosion caused by moisture or dust particles, electronics and appliances require airtight sealing. Furthermore, packaging tape is not designed to withstand high temperatures or extreme conditions that electronics or appliances may encounter during storage or transportation. The adhesive used in packaging tape may not be able to endure heat or cold, resulting in the tape peeling off and leaving the item vulnerable and unprotected. Additionally, electronics and appliances often have delicate surfaces that can be easily scratched or damaged by the adhesive on packaging tape. Moreover, the sticky residue left behind by the tape can be challenging to remove from sensitive surfaces. Therefore, it is recommended to utilize appropriate sealing methods and materials that are specifically intended for electronics or appliances. These options may include specialized tapes, foam gaskets, or custom-fitted protective covers. It is always advisable to refer to the manufacturer's guidelines or seek professional advice when sealing electronics or appliances to ensure proper protection and functionality.

- Q: How do I prevent packaging tape from leaving a sticky residue?

- To prevent packaging tape from leaving a sticky residue, there are a few simple steps you can take. 1. Choose the right type of tape: Opt for high-quality packaging tape that is specifically designed to leave minimal residue. Look for tapes with a low-tack adhesive or those labeled as residue-free. 2. Clean the surface: Before applying the tape, make sure the surface is clean and dry. Wipe away any dust, dirt, or grease using a mild detergent or a rubbing alcohol solution. This will help the tape adhere better and reduce the chances of residue formation. 3. Test in a small area: If you're unsure about the tape's residue potential, it's always wise to test it in a small, inconspicuous area first. Apply a small piece of tape and let it sit for a few hours or overnight. After removing it, check if any sticky residue is left behind. If not, you can proceed with confidence. 4. Remove tape gently: When removing the tape, do it slowly and at a low angle, preferably parallel to the surface. Pulling it too quickly or at a high angle can increase the chances of leaving behind sticky residue. Take your time and be patient to avoid any damage or residue. 5. Use heat or solvent if needed: In case some residue remains, you can try using gentle heat or certain solvents to remove it. For heat, you can use a hairdryer on low setting to warm up the residue and then wipe it away with a clean cloth. If needed, you can also try using rubbing alcohol, white vinegar, or adhesive remover by applying a small amount on a cloth and gently rubbing the residue until it dissolves. By following these tips, you should be able to prevent packaging tape from leaving a sticky residue and maintain a clean surface.

- Q: Does packaging tape have any specific certifications or standards?

- Yes, packaging tape can have specific certifications or standards. There are various organizations and standards that set guidelines for packaging materials, including packaging tape. One of the most common certifications for packaging tape is the International Organization for Standardization (ISO) certification. ISO sets standards for quality management systems, and packaging tape can be certified under ISO 9001:2015, which ensures that the product meets certain quality criteria. In addition to ISO certification, packaging tape can also adhere to specific industry standards such as ASTM International standards or European Union directives. ASTM International develops and publishes technical standards for a wide range of materials, including packaging tape. These standards ensure that the tape meets specific requirements related to strength, adhesion, and durability. Furthermore, some packaging tapes may have certifications related to their environmental impact. For example, certain tapes may be certified as recyclable, biodegradable, or made from sustainable materials. These certifications can be obtained from organizations like the Forest Stewardship Council (FSC) or the Sustainable Forestry Initiative (SFI), which promote responsible forestry practices. It is important to note that not all packaging tapes will have certifications or adhere to specific standards. However, if a packaging tape does have certifications or complies with certain standards, it signifies that the product meets certain quality, performance, or environmental criteria.

Send your message to us

Eco Friendly PVC Electrical Tape Packed with Bags and Carton

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches