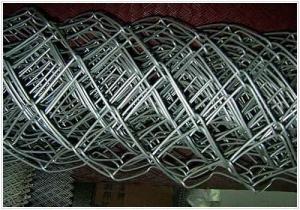

PVC Coated Chain Link Fence With Hot Dipped Galvanized Wire Inside

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

| Type: | Place of Origin: | Hole Shape: | |||

| Model Number: | Frame Material: | Metal Type: | |||

| Pressure Treated Wood Type: | Frame Finishing: | Feature: | |||

| Item: | Material: | Assortment: | |||

| Mesh: | Wire dia: | Length: | |||

| Height: | zinc coating: | Color: | |||

Packaging & Delivery

| Packaging Detail: | woven bags in two edge of rolls |

| Delivery Detail: | 15-25days |

Specifications

Chain link fence

1.Material: low carbon steel wire,stainless steel wire, PVC coated wire.

2.Wire dia 0.2mm~5.0mm

- Q: How does the thickness affect the strength of steel wire mesh?

- The strength of steel wire mesh is directly influenced by its thickness. With an increase in wire thickness, the mesh's strength also increases. This occurs because thicker wires possess a greater resistance to deformation, reducing the likelihood of breakage or bending under pressure. The added thickness enhances structural integrity and boosts the mesh's resistance against impacts or external forces. Consequently, thicker steel wire mesh typically exhibits greater durability and can withstand heavier loads or stresses. Conversely, thinner wire mesh is more prone to damage or failure, as it possesses less material to resist deformation.

- Q: What are the benefits of using steel wire mesh in the automotive industry?

- There are several benefits of using steel wire mesh in the automotive industry. Firstly, steel wire mesh is known for its high strength and durability, making it an ideal material for reinforcing components in vehicles. It can help enhance the structural integrity of various parts, such as car seats, doors, and body panels, leading to increased safety for passengers. Secondly, steel wire mesh offers excellent resistance to impact, corrosion, and wear, making it suitable for use in harsh environments. This property makes it an excellent choice for automotive applications, where vehicles are exposed to various weather conditions and external forces. Furthermore, steel wire mesh provides excellent ventilation and airflow. This is particularly important in the automotive industry, as it helps to regulate temperatures and prevent overheating of various components, such as radiators and engine compartments. This, in turn, improves the overall performance and efficiency of the vehicle. Additionally, steel wire mesh offers flexibility and versatility in design. It can be easily molded into different shapes and sizes, allowing for customization and adaptation to specific automotive applications. This flexibility makes it compatible with various manufacturing processes, making it cost-effective and efficient. Moreover, steel wire mesh is lightweight compared to other alternatives like solid metal sheets, which helps in reducing the overall weight of the vehicle. This weight reduction can lead to improved fuel efficiency and lower emissions, which are essential considerations in the automotive industry's push for sustainability. Lastly, steel wire mesh is an environmentally friendly material. It is recyclable, allowing for the reuse of scrap materials, reducing waste, and minimizing the environmental impact of the automotive industry. In conclusion, the benefits of using steel wire mesh in the automotive industry include its high strength and durability, resistance to impact and corrosion, ventilation properties, flexibility in design, lightweight nature, and environmental friendliness. These advantages make steel wire mesh an excellent choice for various applications in the automotive industry, contributing to improved safety, performance, efficiency, and sustainability.

- Q: How is steel wire mesh used in reinforcement of stadiums?

- Steel wire mesh is commonly used in the reinforcement of stadiums to provide structural strength and stability. It is often installed within the concrete foundation and walls, acting as a reinforcement material that helps distribute the load and prevent cracking or collapsing. The steel wire mesh enhances the overall durability and longevity of the stadium structure, ensuring it can withstand the various forces and stresses exerted during events and regular use.

- Q: Can steel wire mesh be used for machinery guards?

- Machinery guards can indeed utilize steel wire mesh. This material is known for its versatility and durability, effectively safeguarding workers from potential dangers associated with operating machinery. By providing a physical barrier, it prevents direct contact with moving parts, flying debris, or any other hazardous elements. Furthermore, steel wire mesh allows for visibility and ventilation, ensuring safe observation and operation of the machine. Not only is it cost-effective, but it is also easy to install, which explains its popularity in various industrial settings. Nonetheless, it is crucial to ensure that the steel wire mesh used adheres to the necessary safety standards and requirements for the specific machinery and workplace conditions.

- Q: How is steel wire mesh used in reinforcement of water treatment plants?

- Due to its strength, durability, and resistance to corrosion, steel wire mesh is frequently employed in reinforcing water treatment plants. It is commonly integrated into different structural elements to provide additional support and reinforcement during the construction process. One of the primary applications of steel wire mesh in water treatment plants is to reinforce concrete structures. During the pouring process, the mesh is often embedded within the concrete to enhance its tensile strength and prevent cracking or failure when exposed to various loads and pressures. This is particularly critical in water treatment plants, which endure constant exposure to water, chemicals, and harsh environmental conditions. Additionally, steel wire mesh is utilized in constructing retaining walls and underground structures within water treatment plants. These structures must withstand high lateral pressures and provide stability to the overall plant infrastructure. By incorporating steel wire mesh into the concrete or shotcrete used for these structures, they become more resistant to deformation and can better endure the forces exerted by the surrounding soil and water. Furthermore, steel wire mesh is employed in reinforcing filtration systems and holding tanks in water treatment plants. These components require robust construction to withstand pressure differentials and continuous exposure to water and chemicals. By incorporating steel wire mesh into their design, the filtration systems and holding tanks become stronger and more resistant to deformation, ensuring their long-term functionality and reliability. In conclusion, steel wire mesh plays a crucial role in reinforcing water treatment plants. Its strength, durability, and corrosion resistance qualities make it an ideal material for enhancing the structural integrity of various components within the plant. Whether used in concrete structures, retaining walls, filtration systems, or holding tanks, steel wire mesh guarantees that the water treatment plant can endure the harsh conditions it faces, ultimately providing clean and safe water to the community it serves.

- Q: How does steel wire mesh perform in radio frequency shielding?

- Due to its conductivity and ability to block electromagnetic waves, steel wire mesh can serve as an effective material for radio frequency shielding. When utilized as a barrier, it forms a Faraday cage, a structure that prohibits the penetration or escape of electromagnetic fields. Acting as a conductor, the mesh permits the flow of electromagnetic waves while converting their energy into heat, thus dissipating it. This characteristic aids in reducing the intensity of radio frequency signals, effectively shielding the surrounding area from undesired interference. Moreover, steel wire mesh boasts high durability, offering a long-lasting solution for radio frequency shielding, which renders it suitable for diverse applications, including electronic enclosures, data centers, and architectural designs where minimizing RF interference is essential. Additionally, the wire size and spacing within the mesh can be customized to specific frequencies, enabling customization and optimization of the shielding performance. However, it is worth noting that the effectiveness of steel wire mesh in radio frequency shielding can be influenced by factors such as mesh size, wire thickness, and the overall design and installation of the shielding system.

- Q: How is steel wire mesh used in automotive applications?

- Steel wire mesh finds a wide range of uses in automotive applications. One of its primary functions is to reinforce the vehicle's structure. It is commonly employed in different areas, including the front bumper, grille, and body panels, to enhance the vehicle's strength and provide support. Moreover, steel wire mesh serves as a protective measure in automotive applications. It acts as a barrier or guard in areas like the radiator, air intake, and engine compartments, preventing debris, insects, and other foreign objects from entering and causing harm. Apart from its functional purposes, steel wire mesh is also used for aesthetic reasons in automotive applications. It often serves as a decorative element in places like the front grille, adding a stylish and distinctive appearance to the vehicle. Additionally, steel wire mesh possesses thermal and acoustic insulation properties, making it suitable for automotive applications. It can be utilized as a heat shield or sound barrier in areas such as the exhaust system or engine compartment, effectively reducing heat transfer and noise levels. In conclusion, steel wire mesh plays a vital role in automotive applications by offering strength, protection, aesthetics, and insulation. Its versatility and durability make it an excellent material for numerous vehicle components, contributing to their overall performance, safety, and visual appeal.

- Q: Is steel wire mesh resistant to static electricity?

- Yes, steel wire mesh is generally resistant to static electricity. Steel is a relatively good conductor of electricity, meaning that it can effectively dissipate any static charges that may accumulate on its surface. This property makes steel wire mesh less likely to attract or hold static electricity compared to insulating materials such as plastic or rubber. Additionally, the open and interconnected structure of wire mesh allows for easy dispersion of any static charges, further reducing the risk of static buildup. However, it is important to note that the resistance to static electricity can vary depending on the specific composition and design of the steel wire mesh, as well as the surrounding environment.

- Q: Can steel wire mesh be used for waste bins?

- Yes, steel wire mesh can indeed be used for waste bins. Steel wire mesh is a versatile material that offers several benefits when used for waste bins. Firstly, its sturdy construction ensures durability and longevity, making it suitable for heavy-duty use in waste management applications. Additionally, the open design of the mesh allows for proper ventilation, preventing the buildup of odors and reducing the risk of bacterial growth. The holes in the mesh also allow for easy visibility of the waste content, making it easier to identify and sort recyclable materials. Furthermore, steel wire mesh is resistant to rust and corrosion, making it suitable for both indoor and outdoor use. Overall, steel wire mesh is a practical and functional choice for waste bins, providing strength, ventilation, and visibility.

- Q: Is steel wire mesh suitable for use in mining and quarrying industries?

- Steel wire mesh is highly suitable for use in the mining and quarrying industries due to its versatility and durability. It can withstand the harsh conditions and heavy loads commonly encountered in these industries. One of the main benefits of steel wire mesh is its strength, enabling it to endure high tension and impact. This makes it perfect for rock face stabilization, tunnel support, and blast protection. Additionally, steel wire mesh can effectively reinforce and support structures to prevent cave-ins or rockfalls, ensuring the safety of workers and equipment. Furthermore, steel wire mesh is resistant to corrosion and degradation, which is crucial in mining and quarrying operations where exposure to water, chemicals, and abrasive materials is frequent. This resistance allows the mesh to maintain its structural integrity over time, reducing the need for frequent replacements and saving costs. Moreover, steel wire mesh provides excellent visibility and ventilation. It allows for the passage of air and light, creating a safer and more comfortable working environment for miners and quarry workers. This visibility is particularly important for monitoring operations and identifying potential hazards. Additionally, steel wire mesh is easily adaptable and can be customized to meet specific requirements. It is available in various mesh sizes and wire diameters, offering different levels of strength and flexibility. The mesh can be woven or welded, depending on the application and desired characteristics. In conclusion, steel wire mesh has proven to be a reliable and effective solution in the mining and quarrying industries. Its strength, durability, resistance to corrosion, and adaptability make it an ideal choice for a wide range of applications, ensuring the safety and efficiency of operations in these industries.

Send your message to us

PVC Coated Chain Link Fence With Hot Dipped Galvanized Wire Inside

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches