PVC Celuka Plastic Sheets / PVC Free Foam Plastic Sheets / PVC Sheet PVC Celuka Moulding

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Product Introduction

PVC foam sheet is made from polyviny chloride, with flat plate surface, it is widely used in construction, advertising display boards, mounting board, screen printing, carving, etc.

PVC foam board / sheet / pallet is the best material in block making industry as the carrier of the green blocks, it has the advantages of highest strength with smooth surface, moisture proof and heat-resistant, it can maintain stable performance under high temperature. Waterproof,anticorrosive,ametabolic and recyclable,moisture resistant,lightweight.

2. Product Specification

Regular size: 1220*2440mm,1560*3050mm,2050*3050mm,as your required

Thickness:1-33mm

Density:0.35-0.9

3.Product Features

(1) Light weight, waterproof, fire retardant and self-extinguishing

(2) Sound insulation, heat insulation, noise absorption, heat preservation and anti-corrosion.

(3) Tough, rigid with a high impact strength, not easy to age and can keep its color for long

(4)Easy to clean and maintain.

(5)Envioronmental-firendly green and lead-free.

4. Product Application

(1) Advertising: exhibition display, digital printing, silk screen printing, computer lettering,sign board, light box,etc.

(2) Construction: office and bathroom cabinets, inner and outer decorate panel,commercial decorating shelf, room separating

(3) Transportation: steamboat, airplane, bus, train carriage, roof and carriage inner layerand other industry.

5.FAQ

Q: What's the PVC Foam Sheet Processing performance?

A: 1, plastic coating, membrance-stuck and printing

2, with the usual equipment and tools, it can be processed again.

3, welding and bonding

4, cutting and sawing

5, bending when heated-up, thermal forming

6, hole-drilling, Channeling and die cutting

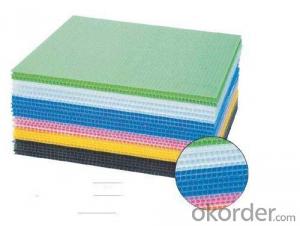

Q: How many colors you have?

A: We have more than 100 existed colors. We can send the color swatch if you leave your message. Also customized colors are acceptable.

Q: If the products have some quality problem ,how will you deal with it?

A: 1,If the quality problem caused by us, we will provide a replacement service,and we must keep in mind.

2,Take measures to control quality strictly,we adhere to the principle: “ quality first”.

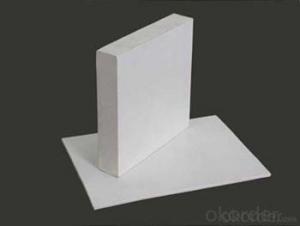

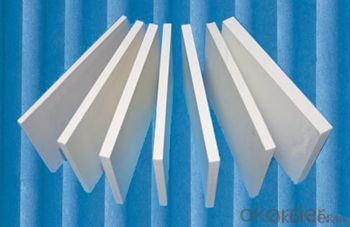

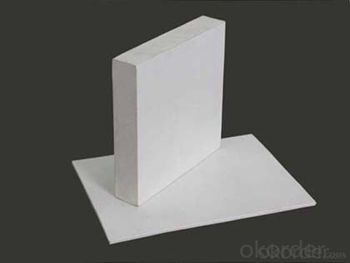

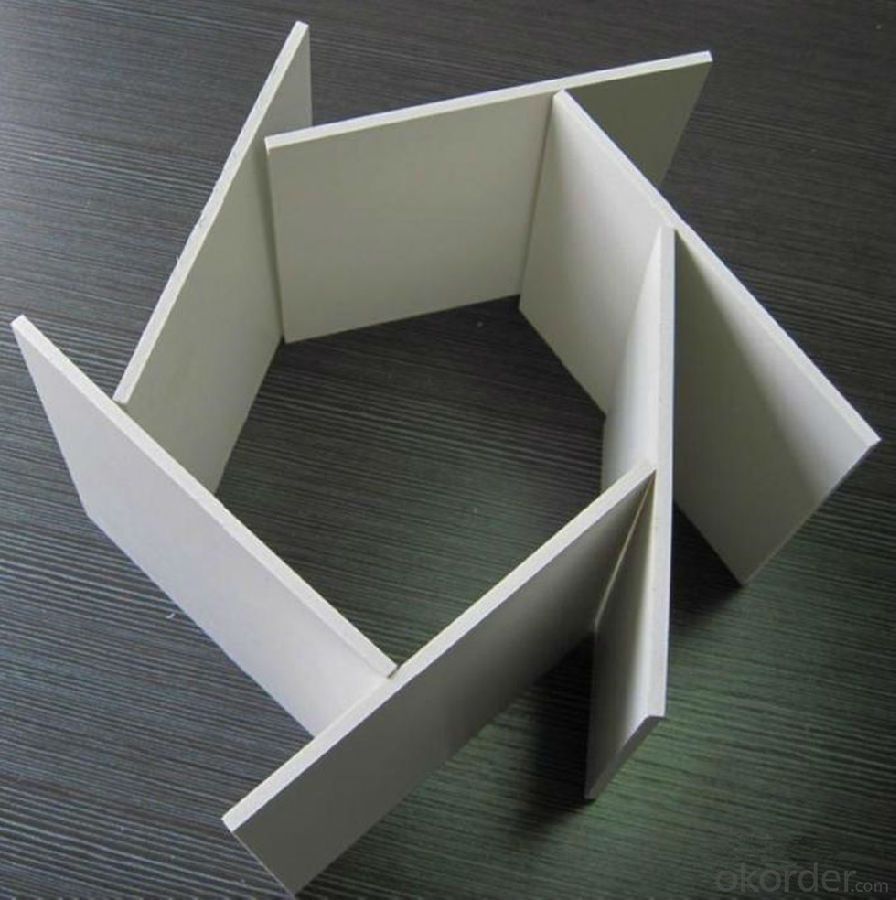

6. Pictures of PVC Foam Sheet

7.Pictures of Factory

- Q: How do plastic sheets handle drilling and cutting?

- Plastic sheets are generally easy to drill and cut, as they are lightweight and flexible. However, the ease of drilling and cutting can vary depending on the type and thickness of the plastic sheet.

- Q: Are plastic sheets resistant to cracking from impact?

- Yes, plastic sheets are generally resistant to cracking from impact.

- Q: i use type 6 plastic[the plastic containers that salads normally come in] as shrink plastic to make shrinkydinks.but i was wondering is there another place to purchase it other than shrinkydinks?easy 10 points.

- I don't think it is anything special. I had one, and ended up getting rid of it. I replaced it with a Segway. Much better, for me at least. Then again, you might just be a Honda Person

- Q: What are the different sizes available for plastic sheets?

- Plastic sheets are available in a wide range of sizes, ranging from small sheets that are a few inches in length and width to large sheets that can be several feet long and wide. The specific sizes available will depend on the manufacturer and the intended use of the plastic sheet.

- Q: if you lay a sheet of plastic over a bar magnet and shake iron filling onto the plastic sheet how will the ir?

- The iron filings will arrange themselves in the direction of the magnetic lines of force. (Try it for yourself and see...)

- Q: Can plastic sheets be recycled into other materials?

- Yes, plastic sheets can be recycled into other materials. The recycling process involves melting down the plastic sheets to create new plastic products, such as bottles, containers, and packaging materials.

- Q: It's a very funny song and my mother would like the sheet music. So if anyone has it or knows where I could get it for free that would be most helpful.

- It was a standard of the Chad Mitchell Trio and I know the song well, but I haven't a clue where you could get the music unless you watch the movie Cool Hand Luke with Paul Newman... he sang that song in the scene after his mother died, so you could get someone to write it down for you. Oh I don't care if it rains or freezes... long as I've go my plastic Jesus... right here on the dashboard of my car.... He is plastic, pink and pleasant... always smiling... ever present... whether I am driving near or far.

- Q: ok im buliding a cage for a client im located in cincinnati ohio and i need to find plastic sheets 8ft long 4ft tall im not looking for plexi glass its to expensive i need just cheap plastic sheets that are thin. if you know what im talking about please help i need to find it asap oh and it needs to be clear.

- Sounds like you are talking about Visqueen (trade name) which should be available at home centers (Home Depot, etc).

- Q: A proton (m= 1.67x10^-27kg) moving at 4.0x10^7m/s shoots through a sheet of foam plastic .25 cm thick and emerges with a speed of 1.5x10^7 m/s A) How long does it take to pass through the plastic?B) What average force retards the proton's motion through the plastic?Hints: Fext T+MVi=MVf Ans: A. 9.09x10^-11s B.4.59x10^-10N

- Ans: A. 9.09x10^-11s B.4.59x10^-10N

- Q: Are plastic sheets fire-resistant?

- No, plastic sheets are not fire-resistant.

Send your message to us

PVC Celuka Plastic Sheets / PVC Free Foam Plastic Sheets / PVC Sheet PVC Celuka Moulding

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords