PVC Ceiling Eaves Wall & Ceiling Panel for Interior Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Description

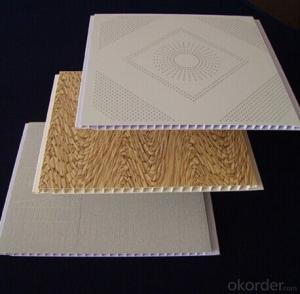

PVC Ceiling for Interior Decoration

We are a professional PVC Ceiling panel manufacture since 1992, offering hundreds of patterns and colors of PVC panel with high quality and competitive price. And monthly output up to 480,000 Sqms.

Different types of PVC Panel we are producing:

1, Glossy PVC Panel (most common type)

2, Sub-glossy PVC Panel (Natural surface handing)

3, High-glossy PVC Panel (high-light surface handling)

4, Transfer Printing PVC Panel

The hottest specifications of PVC panels on the market:

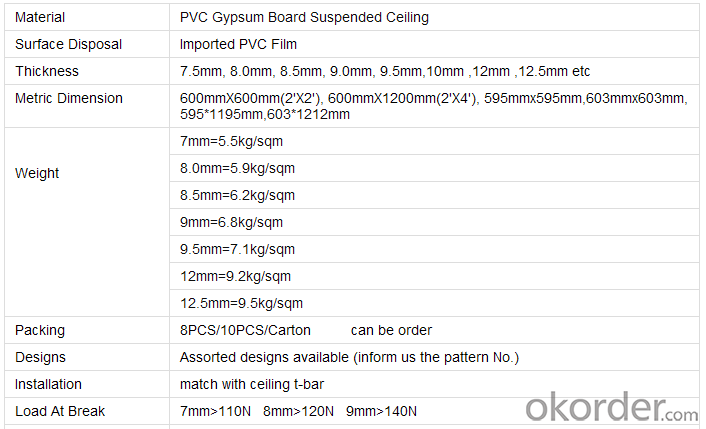

Length: 3m-6m as request.

Width: 200mm/250mm/300mm/600mm

Thickness: 4mm/4.5mm/6mm/7.5mm/8mm/9mm/11mm

PVC percentage: 35%-75%

Specification:

1) Easily installation,surface is smoothness,flatness,without gap when concatenated.

2) High intensity,good quality,not easy to deformation,resist erosion,mothproof,sound insulation,waterproof,fireproof,aging-resisting,durable.

3) It can be processed by drilling,sawing,nailing.Hot bending,hot-folded.

4) Interior decoration for ceiling,wall.Easy cleaning,healthy and environmental.

3.Image

4.Detailed Specification

5.FAQ

Application

The panels are designed for covering internal walls or ceilings in any room in the home or commercial space, but they are specifically conceived for wet environments such as bathrooms, showers, kitchens or utility rooms.

Feature:

1) Easily installation, surface is smoothness, flatness, without gap when concatenated.

2) It can be processed by drilling, sawing, nailing.

3) High intensity, high strength, not easy to deformation, resist erosion, sound insulation, waterproof, fireproof, aging-resisting, durable.

PVC Panel Production Process:

A) Main Raw Material: PVC Resin and Calcium Carbonate, More PVC Resin better quality.

B) Step 1: Mixing Machine mixes the PVC Resin, Calcium Carbonate and others material thoroughly.

Step 2: Molding machine heat the raw material to make it as whole PVC by 230degree temperature.

Step 3: The mold pile out the PVC, and then change it as semi-manufactured PVC panel goods.

Step 4: Put the semi-manufactured PVC panel on the printing machine to print design and color and PVC resin oil on the PVC panel.

About us:

1. Has a certain degree of the scale and efficiency till now

2. Advanced printing machines

3. Twenty lines work together

4. Treat every order with responsibility

5. Rich experience in export to countries from Middle East, South Africa, Southeast Asia, South America and so on.

- Q: Pvc transparent board is building materials?

- Branch Po PVC transparent board: the product is the introduction of foreign advanced technology, the use of advanced imports of raw and auxiliary materials produced by a high-strength, high transparent plastic sheet. The product is high strength, high transparency, good weather resistance, non-toxic, health, physical properties better than plexiglass. Widely used in equipment protection board, interior, drinking water tank, liquid level display. Product color: white, sapphire blue, brown, brown and so on Product thickness: 2-20mm Maximum width of products: 1300mm Product Length: 100-10000mm Recommended Specifications: 1300 × 2000mm

- Q: how to build cat cages out of PVC pipe?

- This is a long article and no pix -- the descriptions good ...look on the net ......... ++ How to Make a Cat Cage Out of PVC Pipe ++of the be sure that you weave the seams of the enclosure wire screen on the outside of the cage -- so, kitty doesn't get snagged ... this is a good idea and the pvc pipe will not rot and should be easy to work with galvanized screen in a 1/2 inch open squares pattern will last a long time ... and plastic zip-ties are easy to work with..... ..... enjoy ... just make a diagram of what you want = lay out what is needed in the pipe and figure the screen cloth when done with the frame == a good PVC pipe cutter is worth that expense to make cutting precise and easy == daub the glue and twist the PVC into the fittings and corners --- some hardware stores have better selections of the fittings you need -- assemble PVC frame parts & fittings and then you can start cutting the frame .............

- Q: Who has pvc foam board performance indicators ah?

- Applicable temperature: -50 degrees Celsius -70 degrees Celsius Heating temperature: 70 degrees Celsius -120 degrees Celsius (making profiles) Bending strength: 45.6mpa Low temperature: (-5 degrees Celsius down the impact) 10 times zero broken life: not less than 50 years Product testing methods: (1) board: smooth and smooth, mechanical texture is not obvious, the surface color without color, milky white, no stains on the surface, no obvious pits, no pinholes, no thick holes, cracks. Note: non-milky white foam plate into the recycling waste plate, does not belong to the environmental protection board, environmental protection board does not lead (content is less than Europe and the United States standard). (2) plate side: incision smooth, fine pores, no pinhole, no thick hole, out of powder is not serious, no honeycomb, open fiber from the fall off, do not jump mouth. Note: The above situation to be careful, and then order to do the finished product trouble. (3) thickness measurement: caliper stand surface, the contact seamless seamless, left and right thickness uniform, left and right measurement, the deviation is large, thickness deviation positive and negative 0.2MM as normal. (4) Plate weight algorithm: Weight (g) = L * W * Thickness (cm) * Density, (5) Density algorithm: Density = Weight (g) / L * W * H (cm).

- Q: What models are pvc boards?

- According to the use of points: industrial, advertising and other, such as plastic used By density points: foam board, hard board, soft board By width: Thickness by thickness: thickness Environmental protection Transparent and many more

- Q: I'm installing a computer and have to drop both power and Ethernet from the ceiling. Will i get interference running the 2 wires close together?

- Yes you can put them together and no you will not receive interference

- Q: Is the heat resistance of the PVC board?

- Do not know where to use it is no problem, the high temperature certainly not work, and long-term high temperature also have an impact on performance.

- Q: The meaning of PVC board

- PVC board is PVC as raw material made of cross-section for the honeycomb mesh structure of the plate, is a vacuum plastic film. For all types of panel surface packaging, it is also known as decorative film, with film, used in building materials, packaging, medicine and many other industries. Which accounted for the largest proportion of building materials industry, 60%, followed by the packaging industry, there are several other small-scale application of the industry. According to the degree of soft and hard can be divided into soft PVC and hard PVC, according to the production process can be divided into PVC leather foam and PVC free foam board.

- Q: Flammability of Polyvinyl Chloride Plastics

- PVC combustion performance is not good, from the fire that is off, the flame was yellow, the bottom was green, white smoke, are flame retardant plastic; burning, irritating hydrogen chloride odor release, softening when burning.

- Q: 2mm thick pvc plastic floor is generally one square meter multiple

- Material is different, the formula is certainly different, the weight is also different,

- Q: What is the difference between acrylic and PVC board?

- PVC board stability is poor, easy to decompose when processing, generally with the same color of the acrylic than the background will be yellow.

Send your message to us

PVC Ceiling Eaves Wall & Ceiling Panel for Interior Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords