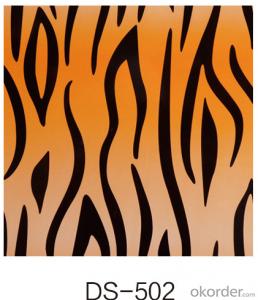

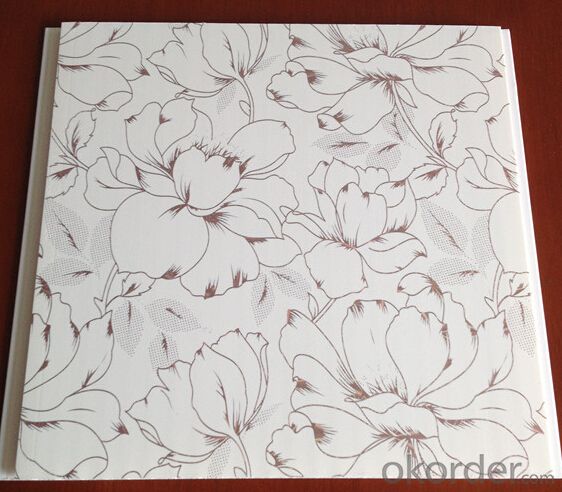

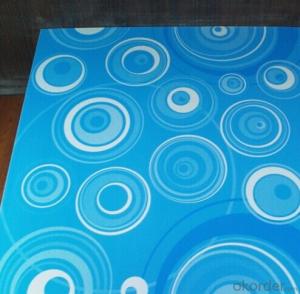

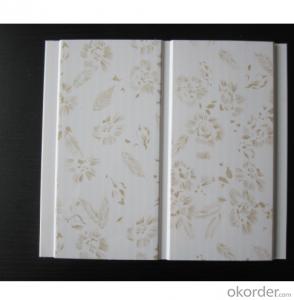

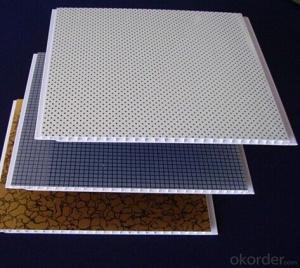

PVC Ceiling Thickness Lamination PVC Ceiling & Wall Panel, Plastic Board

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 30000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

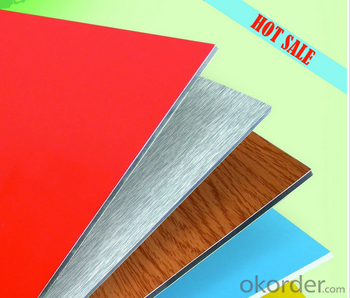

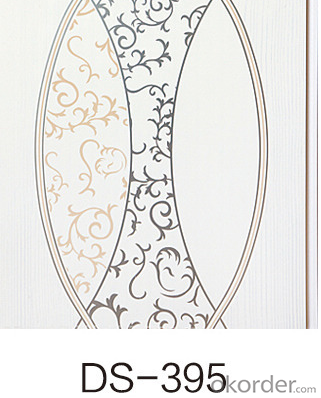

| Type: | Ceiling Tiles | Place of Origin: | Zhejiang, China (Mainland) | Brand Name: | cnbm |

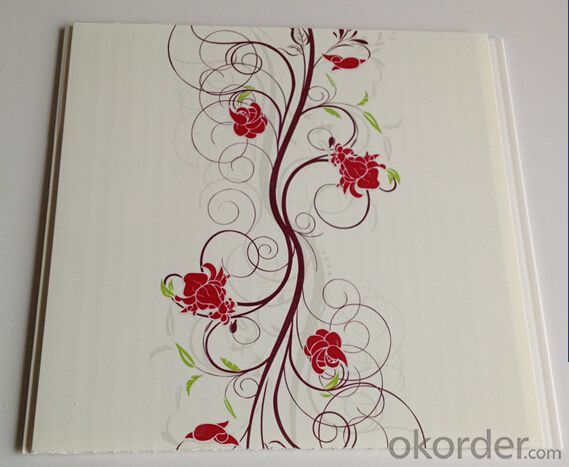

| Model Number: | OP-S1 | Function: | Fireproof, Waterproof | Feature: | Artistic Ceilings |

| Ceiling Tile Shape: | Square | Ceiling Tile Type: | PVC Ceilings | Width: | 250mm |

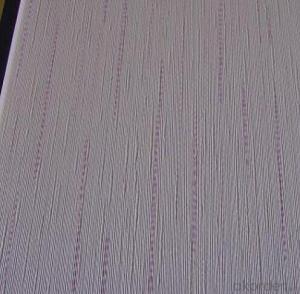

| Thickness: | 8.5mm | Color and Designs: | Hundreds of designs for your chooes,or according to your designs | Surface Treatment: | Laninated printting |

| Certificate: | ISO9001:2008, SONCAP CERTIFICATE | Features: | Waterproof,Stable longevity,Anti-acid,Anti-erosion |

Packaging & Delivery

| Packaging Details: | PVC Shrink-film or PE-Film or Cartons, 10PCS/bale or according to per customers' requirements |

| Delivery Detail: | 10-15days(20GP),15~20 days(40HQ) |

Specifications

Laminated pvc wall panel

1)Certificate:ISO 9001:2008,SGS

2)Surface treatment:laminated printing

3)16 production lines

FAQ

· Can we make an OEM order?

o We can offer or supply goods as customers' requirements.

· How can I get some samples? Free or not?

o We can send some normal samples, absolutely free.

· How does your factory do regarding quality control?

o "Quality is priority." We always attach great importance to quality controlling from the very beginning to the very end. Our factory has gained ISO9001 , SGS authentication, CE for Europe, etc.

- Q: Pvc stamina board can drill their own?

- Yes, but before installation, it is recommended to re-drill, according to the recommendations provided by the manufacturers to install, the plate itself has the characteristics of thermal expansion and contraction, need to reserve space. Hope that the above answer can help you, thank you.

- Q: Stainless steel and pvc board bonding what adhesive

- How big is the adhesive? What are the requirements? I have a high temperature, waterproof seal the structure of plastic, suitable for sticky metal, plastic, glass, etc.

- Q: Polyethylene board is not pvc board? If not, then what is the difference between the two? Thank you

- First, polyethylene, referred to as PE, ethylene is produced by polymerization of a thermoplastic resin. Polyethylene odorless, non-toxic, feel like wax, with excellent low temperature performance (minimum temperature up to -70 ~ -100 ℃), good chemical stability, the ability of most of the acid-base erosion (intolerant with oxidative properties Acid), which is insoluble in general solvent at room temperature, has low water absorption, and has excellent electrical insulation performance. However, polyethylene is very sensitive to environmental stress (chemical and mechanical action) and has poor heat aging resistance.

- Q: Where to buy?

- If you are in the US, you should be able to find them at Home Depots or Menards supply stores. We used the PVC pipes to build agility equipment for our dog.

- Q: How to print on the PVC board, there must be a production process Oh, I have a engraving machine, you can carve PVC board, but do not know how to screen printing

- Need to have a screen ink scraping gum and the like I can give you technical support

- Q: PVC crust foam board business standards or national standards

- The true crust is made with a stoppage method, which forms a layer of dense hard crust on both sides of the sheet, which can improve the hardness and nail force of the plate. These physical properties are very important for the manufacture of furniture or for the decoration of the house. To identify the PVC board is (really) crust, in fact, very simple! As long as the shop does not pay attention to the thumb with the nail on the PVC board pressure, and then carefully check whether there is a deep dent, if there is, is clearly false, it is best not to. Celuka (Celuka) also known as controlled foam method, the current application is very wide, by the French gine kulmann company invented, it is the first patented one of the extrusion foam molding method. The principle of the Luca method is that the outer skin of the melt is compressed and cooled in the styling device directly connected to the die, and the mandrel in the cavity ensures that there is room left when the extrudate leaves the die Through the melt in the mold within the free foam is filled. Cooling strength, core mold size, extrusion speed, can affect the foam core layer density and outer crust thickness. The complex shapes of the profiles produced in this way have the characteristics of low density, high hardness and smooth surface. Baotian Hi-Tech can visit, in addition to their production of PVC crust foam board, but also the production of PVC own foam board, PVC foam profiles, product quality is in the high-end.

- Q: Is PVC material discolored? Decoration with PVC skirting board will have any problems?

- The two are basically able to use, there will be no problem. Only individual manufacturers shoddy, harm the consumer's products are not among them.

- Q: How to remove pvc board of water stains

- Glue or chewing gum: with a professional strong addition to the glue directly on the towel wiping wipe to remove.

- Q: PVC board surface a lot of white spots, what is the reason?

- May be damp long moldy

Send your message to us

PVC Ceiling Thickness Lamination PVC Ceiling & Wall Panel, Plastic Board

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 30000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords