PU Food Processing Conveyor Belt PVC Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 6000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Food Processing Conveyor Belt

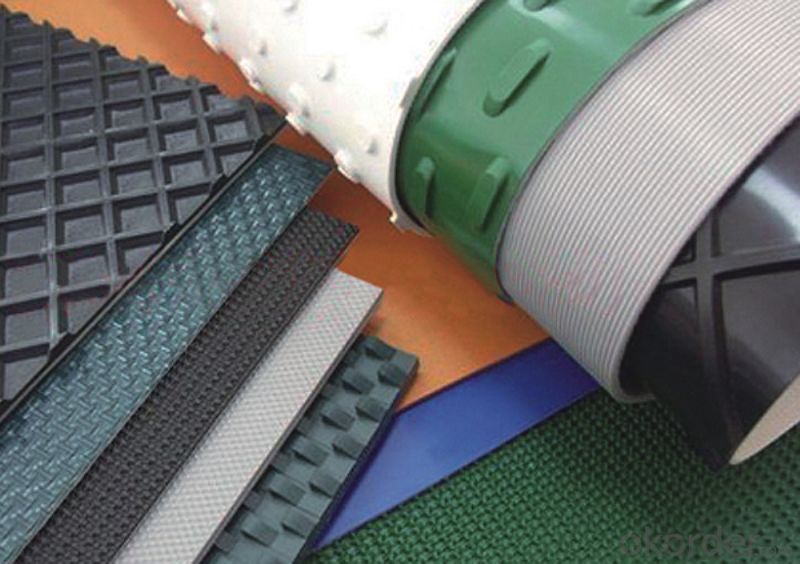

Food Processing Conveyor Belt Introduction

Food processing conveyor belt choose high quality high strength polyester fabric are the core, coated with PU or PVC as loading surface. With advantages of good flexibility, material environmental friendly, light duty, high tensile strength, anti oil, easy learning, our food processing conveyor belt meet EU and USA market requirements.

Food Processing Conveyor Belt Application

Food processing conveyor belt is widely used in food industry, such as vegetables, snack food, beer, sea food, etc.

Food Processing Conveyor Belt Advantage

Food processing conveyor belt is made of harmless material, no toxicity, no smell, anti-oil, easy cleaning, high tensile strength, good flexibility, light weight, solid and durable.

Food Processing Conveyor Belt Specifications

Total thickness(mm) 0.8~5.0 | Top coating hardness( Shore A) 55~92 |

Total weight(kg/m2) 0.9~5.4 | Belt tension 1% elongation(N/mm) 5~ 30 |

Minimum production width(mm) 15~180 | Working temperature range(℃) -20/+90 |

Type of support R=expansion cylinder, S=flat, T=groove shape | Max production width(mm) 3000 |

Lateral stability Yes | Food grade Yes |

Low noise | Fire resistance |

Surface antis tatic |

Food Processing Conveyor Belt Photos

FAQ

1. Which payment do you accept?

For you convenience, our payment can be L/C, TT

2. Is free sample available?

We can supply free samples. You'll just need to pay for express cost.

3. How about your quality?

Quality is the first priority, we have strict quality control system.

1) All raw material we used are environmental freindly

2) Quality Control Department specially responsible for quality checking in each process. We make testing on incoming raw material and finished products. Your third party testing is also welcomed.

3) Skillful workers care every details in handling the producing and packing processes.

Our product quality is accepted by clients from all over the world. Warmly welcome your samples requirement or trail order.

- Q: Can olive nets be used for olive trees in regions with high air pollution?

- Yes, olive nets can be used for olive trees in regions with high air pollution. The nets can serve as a protective barrier, preventing pollutants from directly settling on the trees and potentially damaging the crops. Additionally, the nets can also help in reducing the impact of dust and other airborne particles, thus minimizing the negative effects of air pollution on olive trees.

- Q: How do olive nets help in reducing the risk of root diseases?

- Olive nets help in reducing the risk of root diseases by providing a physical barrier against soil-borne pathogens and pests. These nets prevent the entry of harmful organisms into the soil, thereby protecting the roots from infection or damage. Additionally, olive nets also help in maintaining a more stable and controlled soil moisture, temperature, and nutrient levels, which further contribute to reducing the risk of root diseases.

- Q: How do olive nets help in reducing soil erosion?

- Olive nets help in reducing soil erosion by acting as a protective barrier that prevents soil from being washed away during heavy rainfall or wind. These nets are installed on slopes or areas prone to erosion and effectively trap the soil particles while allowing water to pass through. This helps to retain the topsoil, maintain soil fertility, and prevent the loss of nutrients. Additionally, the olive nets also provide shade, which reduces evaporation and helps to retain moisture in the soil, further preventing erosion.

- Q: Can olive nets be used in combination with fertilization practices?

- Yes, olive nets can be used in combination with fertilization practices. Olive nets are primarily used to protect the olive trees from birds and other animals that may damage the fruit. Fertilization practices, on the other hand, aim to provide the necessary nutrients to the olive trees to promote healthy growth and maximize fruit production. By using olive nets in conjunction with fertilization practices, olive growers can ensure that the trees receive the required nutrients while safeguarding the fruit from potential harm.

- Q: Are there any specific guidelines for using olive nets on dwarf or small-sized olive trees?

- Yes, there are specific guidelines for using olive nets on dwarf or small-sized olive trees. When using olive nets, it is important to ensure that the netting is properly secured and covers the entire tree to prevent birds or other animals from accessing the olives. The netting should be installed before the olives start to ripen to provide maximum protection. Additionally, it is recommended to regularly check and adjust the netting to ensure it remains intact and doesn't cause any damage to the tree or branches.

- Q: How do olive nets prevent fruit damage during transportation?

- Olive nets prevent fruit damage during transportation by providing a protective barrier that prevents the olives from rubbing against each other or getting crushed. The nets also help in maintaining the shape and integrity of the olives, preventing bruising or other physical damage that could occur during transit.

- Q: What are the raw materials used in the production of plastic products?

- Common mineral water bottles and carbonated beverage bottles are made of this kind of material which can not be recycled or hot water. Its heat-resistant temperature is only 70 degrees, only suitable for warm drinks or cold drinks, high temperature liquid or heating, easy to deformation, will dissolve the harmful substances. The scientists also found that the plastic could release carcinogens in 10 months. Therefore, when the beverage bottle is used up, it should be thrown away. It should not be used as a drinking cup or used as a storage container to hold other foods, so as not to cause health problems.

- Q: Are there any environmental concerns related to the use of olive nets?

- Yes, there are some environmental concerns related to the use of olive nets. The nets, if not managed properly, can trap and harm birds and other wildlife that may become entangled in them. Additionally, the use of nets can also lead to soil erosion and impact the overall ecosystem by altering natural processes such as seed dispersal or the nutrient cycle. However, with proper management practices and the use of eco-friendly alternatives, these concerns can be minimized.

- Q: What plastic sunscreen?

- Plastic products are exposed to sunlight or strong fluorescence, causing the aging of plastics due to the ability to absorb ultraviolet light. Adding light stabilizers can reduce the effect of UV light on plastics. Mainly used in PO products, mostly for PE, a few for PP, and PVC, ABS, PS, and so on.

- Q: How do I see if the plastic cup is qualified?

- As a result, the identification of plastic varieties has become simple and easy, and the cost of recycling has been substantially reduced. Today, many countries in the world have adopted the SPI logo scheme. China enacted almost identical labeling standards in 1996.

Send your message to us

PU Food Processing Conveyor Belt PVC Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 6000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords