Professional FRP Panel Machine Manufacture on Hot Sale

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 26 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Professional FRP Panel Machine Manufacture on Hot Sale

Product Advantages:

1.It adopts advanced mechanical structures & technilogy. It has achieved domestic advanced level with advanced technology and reasonable craft, high degree automation and high outputs.

2.It is PLC digital control,including resin feeding.It can achieve vacuum charging resin to doctor blade.Even mixture, easy cleaning and more automation.

3.Easy operation, low noise, obvious electricity conservation, small size, compact structure, low energy consumption, high durability, good looking, etc.

Machine characteristics:

1. Double-layer layout structure, lower the requirement on length of plant.

2. Impregnation platform have multi-line independent temperature control, temperature control is more precise,able to adapt the changing of ambient temperature,speed of impregnation is fast, speed of production is improved effectively.

3. Easy operation based on PLC intellectual control system. Computer control, the production task and equipment operatin data is faster and intuitional. Only short-term training can make operators complete production independently.

4. Roving chopper speed can be synchronous with the production line.

5. Special cross cutting machine and good synchronization performance make cutting accurately.

6. Particular parts adopt special purpose wire, durable in use.

7. Size and layout of machine can be made according to customer requirements.

Basic Parameter:

Name | Professional FRP Panel Machine Manufacture on Hot Sale |

Power Supply | 220V |

Main Frame | 350 H-Beam |

Main Power | 15kw |

Pump Power | 3kw |

Forming Speed | 10 m/min |

Roll Station | Upper Level 11 Stands, Down Level 11 Stands |

Roller Diameter | 70mm |

Hydraulic Pressure | 10-12 MPa |

Forming Size | 840mm, 900mm |

Feeding Thickness | 0.3-1.2mm |

Feeding Width | 1000mm |

Backboard Thickness | 14mm, 16mm |

Chain Size | 20mm |

Cutter Standard | Cr12 |

Roller Standard | Cr12 |

Cr-Plating Size | 0.05mm |

Overall Size | 7500*1700*1300mm |

Total Weight | 3T |

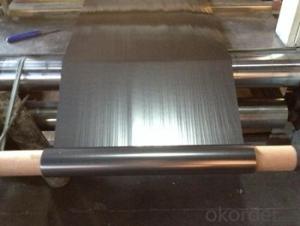

Pictures:

FAQ:

Q: Why we are your best choice?

A:We have direct factory and many years of export experience, and offer the best price with high quality product, timely delivery, also have good after-sales service, therefore with good reputation on boards and with many clients have good long-term business relationship.

Q: Can I order the product with special size?

A: Of course you can, also we will produce the products according to your detail requests.

Q:What Is The MOQ?

A:MOQ depends on different items.

- Q: What are the requirements of customers for nylon plastic products?

- The advantage of nylon nylon is that its thermal properties, mechanical properties, flame retardance and barrier properties are higher than pure nylon, and its manufacturing cost is equal to that of ordinary nylon. Therefore, it is very competitive.The flame retardant nylon for electronic, electrical and electrical appliances is increasing day by day, and green flame retardant nylon is paid more and more attention by the market.Antistatic, conductive nylon and magnetic nylon will be the preferred materials for electronic equipment, mining machinery and textile machinery.Research and application of the processing aids, will promote the function and modification of Nylon high performance process.The application of the integrated technology, the fine product is the impetus of the development of the industry.If you make nylon products, there are a lot of directions to choose from.

- Q: Which kind of engineering plastics can be machined on machine tools?

- General raw materials market is available, you can also contact the internet.

- Q: Who knows Guangdong province processed waste plastic particles Factory where. Thank you

- Guangdong is very large! Where is there, where is the friend? Guangdong is more than Shunde, the most prosperous town, I work here in Guangdong, Zhongshan Province plastic granulation machinery factory.

- Q: What is plastic processing of moulds?

- With the rapid development of plastic industry and the continuous improvement of general and engineering plastics in the field of strength, the range of application of plastic products is also expanding, and the consumption of plastic products is also rising.A plastic mold is a tool for the manufacture of plastic products consisting of a number of parts in which the molding cavity is formed. Injection molding, mold clamping in injection molding machine, the molten plastic is injected into the molding cavity, and cooling in the cavity shape, and then die down to separate out the system through the top products from the top of the left mold cavity, the mold is closed again for the next injection, the injection molding process is carried out of the cycle.The general plastic mould is composed of two parts, the moving die and the fixed mould. The moving die is installed on the moving template of the injection molding machine, and the fixed die is installed on the fixed template of the injection molding machine. In the injection molding, the moving die and the fixed die are closed to form a casting system and a mold cavity. When the mold is opened, the moving die and the fixed die are separated so as to remove the plastic product.

- Q: Which kind of plastic is good for machining?

- Generally can be processed, mainly in the tool and process control

- Q: Rubber, plastic, machining specialty, which university is good?

- Dalian Light Industry Institute, Tianjin College of Light Industry, Chengdu University of Science and Technology are good.

- Q: What are the processes and machines used in the manufacture of plastic products?,

- In recent years, the proportion of plastic products is increasing rapidly in many fields, such as household appliances, instruments and meters, building materials, automobile industry, daily hardware and so on. The requirement of high precision and high performance of plastic products increases with each passing day, which makes the precision forming technology progress constantly. Injection molding is one of the most important plastic forming methods, and many factors affect the precision injection molding. 1. in the early stage of the design of plastic products, injection molding materials should be selected according to their application environment. 2. precision molds, rational design of precision injection mold is the basis and necessary prerequisite for precision products. Precision molds are indispensable to produce precision products. The precision of the die is usually affected by the temperature control of the die, the precise manufacture of the die and the choice of the plastic shrinkage when the die is designed. 2.1 control of the mold temperature due to the effect of mold temperature on shrinkage molding, but also directly affects the mechanical properties of plastic products, can also cause various defects of product surface flooding, so must keep mold in the specified temperature range, but also to make the mold temperature changes over time. In the injection molding of general precision parts, the temperature of the die is controlled mainly to increase productivity. But the impact of temperature control of mold for injection molding is great, it affects parts of the shrinkage, shape, crystallization, internal stress, so the design of mold hot loop temperature distribution at the request reasonable precise control accuracy, the best use of mold temperature machine and cold water machine control.

- Q: What's the price? How much does it cost to run a processing plant? What's better about that one?

- The material is mainly petExtrusion blowing is a molding process. The machine is the corresponding extruder and mold and auxiliary machineWhich one you use depends on what shape and material your bottle isI hope I can give you some help

- Q: Laizhou plastic processing plastic machinery and equipment, which is more reliable, relatively good?

- you have this problem too vague, but also do not know you to play some bottom in figure what product, change a problem to try again

- Q: What kind of units do you need to process plastic injection products?I own the business, there are plastic injection molding machine more than, can produce all kinds of plastic products, order ~ unit in Hangzhou ~!

- It's easy to come out of the classified trade ads in the newspaper magazines in Hangzhou

Send your message to us

Professional FRP Panel Machine Manufacture on Hot Sale

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 26 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords