Professional FRP Panel Machine Manufacture with Good Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 21 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Professional FRP Panel Machine Manufacture with Good Price

Product Description:

1.It adopts advanced mechanical structures & technilogy. It has achieved domestic advanced level with advanced technology and reasonable craft, high degree automation and high outputs.

2.It is PLC digital control,including resin feeding.It can achieve vacuum charging resin to doctor blade.Even mixture,easy cleaning and more automation.

3.Easy operation, low noise, obvious electricity conservation, small size, compact structure, low energy consumption,high durability, good looking, etc.

Product Features:

1. Special cross cutting machine and good synchronization performance make cutting accurately.

2. All the machine parts adopt international standard steel make machine with high stability.

3. System failure can be automatically alarmed and show fault point. Make maintenance easily

4. Particular parts adopt special purpose wire, durable in use.

5. Size and layout of machine can be made according to customer requirements.

Product Parameter:

Name | Professional FRP Panel Machine Manufacture with Good Price |

Brand | CMAX |

Weight | 9T |

Dimension(L*W*H) | 880x620 X1120 |

Power | 20KW |

Voltage | 220V 50HZ |

Product Type | FRP Machinery |

Certification | ISO9001:2008 |

Application | Pipe |

Raw material | Fiber Reinforced Plastic |

Place of Origin | Beijing, China (Mainland) |

Color | Customized |

Warranty | 1 Year |

Time of Delivery | 30-45 days |

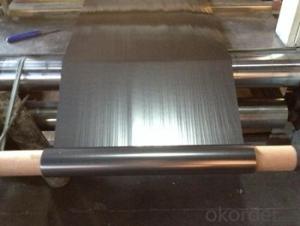

Product Pictures:

FAQ:

Q: Why we are your best choice?

A:We have direct factory and many years of export experience, and offer the best price with high quality product,timely delivery, also have good after-sales service, therefore with good reputation on boards and with many clients have good long-term business relationship.

Q: Can I order the product with special size?

A: Of course you can, also we will produce the products according to your detail requests.

Q:What Is The MOQ?

A:MOQ depends on different items.

- Q: The next 5 to 10 years, small workshops waste plastics processing prospects for development?

- Reference to prospective Industries Research InstituteAnalysis of production demand and investment forecast of modified plastics industry in China in 2015-2020The plastic machinery industry is the machinery manufacturing industry which provides important technical equipment for the plastic raw material industry and the plastic products processing industry. It is the floorboard of all kinds of machinery and equipment used in the plastics processing industry. After years of development, China's plastic machinery industry has initially formed a relatively centralized production cluster. Mainly distributed in Bohai, the Yangtze River Delta and the Pearl River Delta three regions.Since twenty-first Century, China's plastic machinery industry has been sustained and rapid development, is one of the fastest growing industries in the country, the main economic indicators among the forefront of the national machinery industry. With the development of chemical, mechanical, electronic and other related technologies, the status of plastics and plastic machinery in human economic life will be further improved. Plastic machinery enters our country to develop industry with advantages. China's plastic machinery industry has gone through years of entrepreneurship and development. Production enterprises are mainly located in the coastal areas of Southern China and East China, employing tens of thousands of technical level to improve rapidly, and achieved good sales performance in the international and domestic markets. The main products of the plastic machine industry overall upward market image. Industrial output value, sales and profits and taxes have been increasing at the same pace. Overall, plastic machinery has entered the ranks of China's dominant development industry.

- Q: Which plastic is suitable for processing 3mm threaded holes and is best resistant to corrosion?

- Nylon plastic is suitable for processing 3mm thread hole, nylon is widely used in chemical machinery, corrosion protection equipment, gear and parts, broken material.

- Q: I want to make some plastic products. Thank you。 FiveThe four type: first, a one or two meter long, hard, but bent plastic tube. Then there's something like the front end of the syringe. And then a small plastic kettle. Finally, a small thing that can be secured to the mouth of the pipe.

- The first thing for PE is certainly no problem, PE pipe can be bent, there are a variety of diameters and specifications to the number of how many, still a little hard oh.

- Q: I am going to work as a worker in a plastics factory. I wonder if the work inside it is very polluting. Is there any harm to the health?

- The market has been the emergence of more environmentally friendly alternatives such as polypropylene foam, honeycomb paperboard and pulp molding products, recycling mechanism should be set up this kind of packaging materials, such as increasing the recovery of kinds of cushioning packaging materials in the recycling, the environmental protection material to be vigorously promoted.Because of its inability to degrade naturally, plastics have caused many animal tragedies. For example, the monkeys in the zoo, pelicans, dolphins and other animal, are readily lost visitors swallowed 1 plastic bottles, and finally as indigestion and painful death; looked beautiful and pure sea, approaching the look, in fact, filled with various kinds of unable to accommodate the oceans of plastic waste, in more than one the dead birds sample intestines, that cannot be digested all kinds of plastic.The most dangerous of plastic products is phthalate two, a substance that causes the decline in sperm counts in men. The EU has already banned cosmetics, teething rings and chew toys for children using a variety of phthalate two formate. Still, pregnant women are exposed to phthalates, which are often used to soften household items, such as plastic furniture, shoes, PVC floors, and plastic for shower curtains, two.

- Q: Laizhou plastic processing plastic machinery and equipment, which is more reliable, relatively good?

- In contrast to many manufacturers of plastic processing equipment, more important is environmental protection, there is calm in the future, if you want to buy the equipment you can go to Laizhou city to take a look at the field, there are a lot of home doing well, you have this problem too vague, but also do not know you to play some bottom in figure what product, change a problem to try again

- Q: I did not come into contact with the plastic design, to understand the mechanical design and traditional design of plastic parts and fittings of the (metal material) are different, from what kind of material, design, drawing standards, labeling etc.. Please engage in plastic design industry heroes pointing!

- Material selection, according to experience, can not, then check the mechanical manual, drawing standards are also divided into metal box, plastic? Without distinction. In fact, the plastic design and metal design, the key lies in what is their manufacturing process! I don't see how long your mechanical design of metal has been done!I hope my answer will help you. Thank you for taking it

- Q: What method or machine do you want to throw bright?

- Some plastic products come out very smooth, not in plastic polishing, polishing on the mold

- Q: What chemicals should be used in plastic products?

- Several commonly used plastic additivesPlastic additives can be divided into seven categories according to their specific functions: additives for improving processability, such as thermal stabilityA constant agent, lubricant, etc. Additives for improving mechanical properties, such as plasticizers, toughening agents, etc.. The changeAdditives for good surface properties, such as antistatic agents, coupling agents, etc.. Additives to improve optical properties, such asColorant, etc.. Additives to improve aging properties, such as antioxidants, light stabilizers, etc.. The reduction of plasticAn additive such as an extender, a filler, etc.. The specific effect of giving other additives such as foaming agent,Flame retardant and anti mildew agent etc..Additives are meant to be dispersed in the plastic molecular structure without serious impactA chemical structure of plastics that improves its properties or reduces its cost. Addition of additives, energyThe plastic can improve the processing, physical and chemical functions of the base material and increase the physics and chemistry of the base materialCharacteristic。

- Q: What milling cutters are used for processing plastics?

- Therefore, the plastic processing, the tools used and the corresponding cutting speed, etc., should be adapted to plastic characteristics.With the usual knife like T15 but nagging note "don't have to wear the knife edged quickly.

- Q: How do we calculate the cost?

- So many people bought equipment and started, most of the friends have just started, mainly chemical fiber bags (PP woven bags) granulation, plastic film granulation, plastic bottles, broken materials, and so on.2, followed by the main problem is the use of equipment:1). Performance of the equipment are not familiar with the problems of using too much, such as temperature control is not good (low price devices do not have automatic temperature control system, through experience), products can not achieve the desired requirements, the color is not good, drawing off a serious, low yield, often blocking filter, cutting unevenness, severe adhesion.2) raw materials sorting is not clear, cleaning is not in place, impurities, broken bar serious, bad color. The same raw materials, the same approach, the product is not as good as others, the price is far from.3), procurement of raw materials, usually all recycled plastic, when you formed a batch production, to ensure the supply of raw materials can not be too much, impurities in raw materials procurement, and even pit you encounter people, buy a home is water, stone bag.4) sales problems: I don't know who sells the products. I don't know what the price is, or even say you have such and such problems.Moreover, the beginning of production, it is impossible to form mass production, small amount of bad sales, because customers need to be generally enough to a car to load, 2T-3T is not good, and more afraid of production, fear of backlog.

Send your message to us

Professional FRP Panel Machine Manufacture with Good Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 21 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords