Reliable Reputation FRP Pultrusion Machine with High Quality and Low Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 21 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

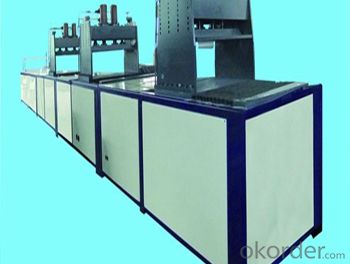

Reliable Reputation FRP Pultrusion Machine with High Quality and Low Price

Product Description:

We offer high performing FRP Pultrusion Machine that is highly appreciated in various industries. Our Pultrusion

Machine is manufactured from the optimum quality raw materials to assure high durability. Hydraulic Pultrusion

Machine and Crawler Pultrusion Machine offered by us is perfect for the manufacturing of F.R.P. (Fiberglass

Reinforced Plastic) sections, solid rods, tube sections etc. High speed of our Industrial Pultrusion Machine ensures

its maximum productivity in minimum time. We have firmly positioned ourselves as one of the prime Industrial

Pultrusion Machine manufacturers and suppliers based in China.

Product Features:

1.The main machine is steel structure, stainless steel panel, side panel is paint. With the two kinds of pultrusion

modes:Debugging and succession, it is convenience to adjust the production craft;

2.Traction gantry makes ordered according to requested length.

3.The machine had two hydraulic pressure system, it had strong ability of anti-interference;

4.Using function: it have single and double manually operated gantry and double gantry automatic reciprocating

running function. Automatic intermittent time can be automatically settled, and the actual production tension can be

feedback by sensor.

Product Parameter:

Name | Reliable Reputation FRP Pultrusion Machine with High Quality and Low Price |

Brand | CMAX |

Weight | 6T |

Dimension(L*W*H) | 7.98mX0.75mX1.5m |

Power | 37KW |

Voltage | 240-380V |

Product Type | FRP Machinery |

Certification | ISO9001:2008 |

Application | Profile |

Raw material | Fiber Reinforced Plastic |

Place of Origin | Beijing, China (Mainland) |

Color | Customizable |

Warranty | 18months |

Time of Delivery | 30-45 days |

Product Pictures:

Our Services:

1. Warranty period: 18 months.

2. Spare parts: Non-artificial damage parts, during warranty period, can be provided free of charge.

3. Testing and debugging: Every machine will be tested and debugged before shipment.

4. Training and maintaining: Sending our engineer to your factory or sending your machine operator to

our factory.

FAQ:

Q1:How Can I Get A Sample?

A1:You can get samples by communicate with our export sales.

Q2:How Long Is Delivery?

A2:Delivery time will be30-45days according to order quantity.

Q3:What Is The MOQ?

A3:MOQ depends on different items.

- Q: Types of plastic machinery

- Characteristics of injection molding machine control system:1. 、 adopt advanced computer control of famous factory;2. self diagnostic fault function;3. direct input pressure, speed, time, travel and temperature data;4.LCD color liquid crystal display (pictured below);5. centralized lubrication;6. pressure coupling circuit saves power;7.24 V DC oil pressure directional valve coil never damaged;8. die cooling water regulator;9.M.C.B. insurance electrothermal control;10. advanced computer control system, large screen display, operation interface, easy to use cylinder;11. high-precision electronic ruler stroke control, accuracy up to + 0.1mm;12. improve reproducibility by using pressure and oil feedback;13. mechanical, electrical, hydraulic 3 heavy safety devices, in any case can ensure the safety of the operator (PD60-PD148 matching oil pressure);14. improve the reproducibility and operability by installing superior position sensors;15. using closed-loop control to achieve ultra precision forming.

- Q: How can rubber products be machined?

- The mechanical processing of rubber products is a general term for processing plastic products by mechanical means. The types of mechanical processing of plastic products, mainly cutting, punching, cutting, drilling, thread processing, laser processing, etc..

- Q: The processing of plastic bottles

- The production process of plastic bottle has two kinds: the first kind is extrusion blowing process, the plastic raw materials into the extruder, the melting extruding molten parison, then put the bottle mold blow molding, cooling after removed from the mold, eliminating waste edge to be finished after. This process is mainly used to produce polyethylene, PVC plastic bottles, such as milk bottles, soy sauce bottles and so on. The second is the plastic material injection stretch blow molding process, the injection molding machine injection molding tubular billet, then put the bottle mould through stretch blow molding, cooling after the finished product is obtained. This process is mainly used to produce PET plastic bottles, such as mineral water bottles and so on.

- Q: How much profit can a ton earn? Is it difficult to operate the program?

- Do not make money, you see the location of the market demand, the ability to digest and competition with the industry and other aspects, in general even if money is earned a hard-earned money, profit general in 200-500 tons, and raw materials and sales organizations should be guaranteed, otherwise it is difficult to open the market.

- Q: What machines do you need? Where can I get the raw material? Thank you

- Now online can buy, of course, the machine on the spot to look goodCup making machine, bowl making machine, printing press, drawing machine, almost

- Q: Such as "computer embroidery processes" - Programming - sample preparation, shipment packing production computer

- Process flow of plastic products1. Preparation before moldingA, grain preheating and drying: if the grain is affected with damp, it should be dried;B, insert preheating: in order to reduce the gap between the cooling shrinkage value of metal and plastic, the larger metal insert should be preheated.C, barrel cleaning: when changing the product, changing the raw materials, cleaning cylinder is required.2, injection molding process feeding - plasticizing - injection - holding pressure - cooling - die opening piecesA, feeding: each feeding should be quantitative, in order to ensure uniform plasticization;B and plasticization: the grains are heated to a molten state in a barrel;C and injection: the injection molding machine uses a screw to inject molten plastic into the mold cavity;D, keep pressure: after the mold is finished, maintain the pressure for a certain time;E and cooling: keep cool for a certain time in the mold cavity;F, mold opening parts: mold open, take out the product.3, plastic parts after treatment: plastic parts after treatment:A, remove the fly edge, material handle.B, inspection and packing.

- Q: I did not come into contact with the plastic design, to understand the mechanical design and traditional design of plastic parts and fittings of the (metal material) are different, from what kind of material, design, drawing standards, labeling etc.. Please engage in plastic design industry heroes pointing!

- Material selection, according to experience, can not, then check the mechanical manual, drawing standards are also divided into metal box, plastic? Without distinction. In fact, the plastic design and metal design, the key lies in what is their manufacturing process! I don't see how long your mechanical design of metal has been done!I hope my answer will help you. Thank you for taking it

- Q: Plastics are processed into raw materials. How much raw material and energy do we need to process a kilogram of plastic?

- Is the necessary equipment for extrusion blow molding machine, you must first set up the company, production workshop, production equipment, testing equipment, inspection personnel and production licenses for the government, as the raw material is plastic particles, costs and profits can not be known, see you how to operate.

- Q: What chemicals should be used in plastic products?

- Additives mainly in the following categories:OneAntioxidantsAntioxidantUnsaturated double bonds in plastics are absorbed by oxygen atoms, heat and lightCaused by breaking, resulting in free radicals, which cause a chain reaction, so that the molecular chain scission or formation of chain cross-linking,Resulting in lower or weaker strength of plastic products. The function of antioxidants is to delay the oxidation of plasticsBreak down and prolong the life of plastic products. The antioxidants used in the plastics industry can be divided into functions: (One)Inhibitors of oxidative chain reactions, such as alkylphenolAlkylPhenolButyl tolueneButylatedHydroxytolueneAbbreviationBHT) aromatic aminesAromaticAmines) phenyl - -B-Resistant amine(Phenyl-B-Naphthylamine), were of Kun (AlkylQuinoneAlkenyl bisphenol A(AlkyleneBisphenolAlkyl phenol sulfideAlkylPhenolthioetherSalicylic acidBenzene fingerPhenylSalicylateAnd so on) etc.. (

- Q: I would like to open a waste plastics processing granules factory, to those techniques and attention. What are the processes?

- (two) technical guidelines for the purchase of advanced waste plastics granulator;First, the characteristics of advanced waste plastics recycling machine:1 、 high efficiency and energy saving (high output, electricity saving);2, environmental protection (supporting cleaning machine, using recycled water, no sewage);3, the quality of vulnerable parts (especially screw) (after nitriding or 45 steel quenching and tempering, strength treatment);4, specific requirements:The power consumption per ton of granulation shall not exceed 300 degreesBring water productionDrainage and exhaustThe automatic non-stop screen changing (preferably two)The produced particles have a high degree of finish and compactnessThe mechanical properties, leading screw designThe application of HDPE (high density polyethylene), LDPE (low density polyethylene), PP (polypropylene), PS (polystyrene), PC (polycarbonate), PVC (polyvinyl chloride) resin, regeneration granulation, granulation, powder granulation PET and ABS all kinds of plastic.The customer service service.Single screw mixing head equidistant designThe double screw feed, coal (gas) dual power11, material: 38CrMnAl, at least 45# steel quenched and tempered screw12, accidental protection device "cross slider.""13, a number of wet dual-use, longer on the machine. But the general water making machine barrel length not less than 2 meters, otherwise easily was born (refers to electricity)14, models should be 120, 180 and 150, the ratio of length to diameter in 16:1 - 20:1 is appropriate

Send your message to us

Reliable Reputation FRP Pultrusion Machine with High Quality and Low Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 21 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches