Prime Quality Tinplate Sheets for DUBAI Market

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure Description

Electrolytic Tinplate Sheets is one of the metal packing materials, which is widely used for making painting cans ,chemical package cans , electrical cable ,battery and metal printing etc.

2. Main Features

Steady and high quality

Fast shipment

Good experience for export work

For the surface, Plate uniform in thickness,uniform and smooth tin coating, without flaws,rusts,scratch,wave,nick of tin coating etc.

Price competitive

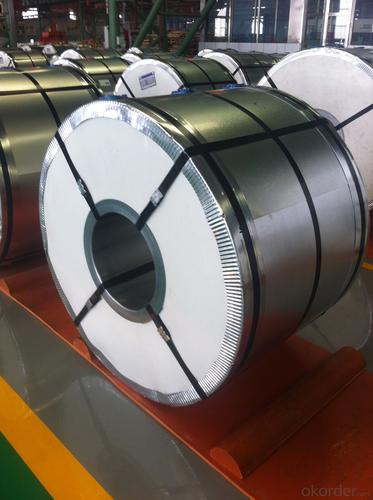

3.Images

4. Specification

Standard : GB2520-2000 ,JIS G3303

Steel type : SPCC

Coating : 2.8/2.8

Surface: Bright, Stone ,

Thickness:0.26

Width :600MM~1000MM

Temper : T1~T5

Package: tinplate wrapped completely with an inner cover of plastic or waterproof papers with vorners protected with metal angels.

5.FAQ

A. What is the package of tinplate? (Referred as below)

For sheets, thin plastic film + rust-proof paper + metallic cover + metallic angles+ steel band strips + fumigated wooden pallet.

For coil, thin plastic film + rust proof paper + metallic cover + steel band strips + fumigated wooden pallet

B. The surface of tinplate could you supply?

Stone finish, Bright finish, Matte finish, Silver finish

C. What quantity is the minimum order of tinplate?

Usually, the minimum quantity is 25MT. For special case, consult with us.

D. Can it make to be BA or CA for annealing?

Yes, both can do with.

- Q: What are the common storage and handling requirements for tinplate?

- The common storage and handling requirements for tinplate include keeping it in a clean and dry environment to prevent rusting or corrosion. It should be stored in a well-ventilated area away from direct sunlight and sources of heat. Tinplate should be handled with care to avoid any sharp impacts or bending, as it can affect its structural integrity. It is also important to stack tinplate properly, ensuring that there is no excessive weight on top of it to prevent deformation. Regular inspection and maintenance are necessary to detect any signs of damage or corrosion early on.

- Q: Why do tin tins rust easily when they are opened?

- It turned out to be sealed and oxygen has been transpiring. When opening is oxidized (Fe2o3), there is rust.

- Q: What are the challenges faced in the recycling of tinplate?

- One of the main challenges in recycling tinplate is the separation of tin from steel. Tin is a non-ferrous metal, while steel is ferrous, making it difficult to separate the two during the recycling process. Additionally, the presence of organic coatings or other contaminants on the tinplate can further complicate the separation process. Another challenge is the high energy consumption required to melt and separate the tin from the steel, which can impact the overall efficiency and sustainability of the recycling process. Finally, the collection and sorting of tinplate waste can also be a logistical challenge, as it requires proper infrastructure and coordination between households, businesses, and recycling facilities.

- Q: How is tinplate coated for automotive components?

- Tinplate for automotive components is typically coated through a process known as electroplating. In this method, a thin layer of tin is deposited onto the surface of the steel substrate through an electrochemical reaction. This coating provides protection against corrosion and also enhances the aesthetic appearance of the automotive components.

- Q: How does tinplate perform in high-temperature applications?

- Tinplate performs well in high-temperature applications due to its excellent heat resistance and durability. It can withstand elevated temperatures without warping, melting, or releasing harmful substances, making it a reliable choice for various industrial and packaging uses.

- Q: What are the main applications of tinplate in the marine industry?

- Tinplate is commonly used in the marine industry for various applications including the production of cans and containers for storing food, beverages, and other supplies on ships. It is also utilized for manufacturing components such as panels, fittings, and structural parts due to its corrosion resistance and durability in marine environments. Additionally, tinplate is employed in the construction of ship hulls, bulkheads, and decks, providing protection against rust and enhancing the longevity of marine vessels.

- Q: What are the common surface treatments for tinplate?

- The common surface treatments for tinplate include electrolytic tin plating, chrome plating, and lacquering.

- Q: What are the advantages of using tinplate for gift packaging?

- One of the advantages of using tinplate for gift packaging is its durability. Tinplate is a strong and sturdy material that can withstand rough handling and protect the contents of the gift. Additionally, tinplate is resistant to corrosion and can keep the gift in good condition for a longer period of time. Another advantage is its aesthetic appeal. Tinplate can be easily decorated and customized, allowing for unique and eye-catching gift packaging designs. It also gives a premium and luxurious feel to the gift, enhancing its overall presentation. Lastly, tinplate is eco-friendly as it is recyclable, making it a sustainable choice for gift packaging.

- Q: Are there any limitations to using tinplate packaging?

- Yes, there are a few limitations to using tinplate packaging. Firstly, tinplate packaging is relatively heavy compared to other packaging materials, which can increase shipping costs and carbon footprint. Additionally, tinplate packaging is not suitable for certain products that require transparency or visibility, as it lacks transparency. Lastly, tinplate packaging may corrode if it comes in contact with acidic or alkaline substances, limiting its use for certain types of products.

- Q: The composition of tinplate?

- There are other statements, such as China used this lamp tin plate made of kerosene, shaped like a horse, so called "tin".

Send your message to us

Prime Quality Tinplate Sheets for DUBAI Market

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords