High Quality of Tinplate for Cookie Cans

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

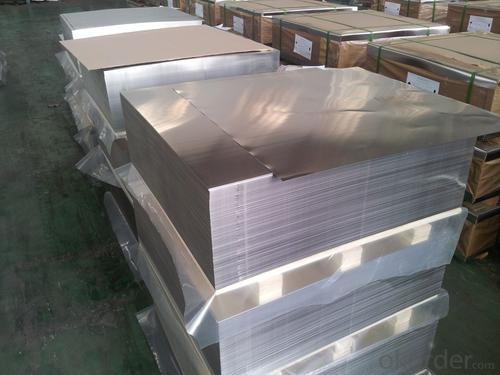

Our tin plate (TP) products are made by coating tin using electrolysis on the surface of thin coldrolled steel sheet (black plates), with a thickness of 0.14~0.6 mm. Its shiny surface finish, superb corrosion resistance and formability make tin plates an ideal choice for the food industry and industrial parts producers. Our tin free steel sheet (ECCS) is widely accepted as a more economical substitute for the tin coated steel. Our TP/TFS products are widely used in the production of 3-piece and 2piece (D&I, DRD) cans as well as can lids and bottoms. Our products serve a variety of purposes, including material for steel EOE, toys, and electronic parts.

Our Tinplates Specification:

Standard: ISO 11949 -1995, GB/T2520-2000,JIS G3303,ASTM A623, BS EN 10202

Material: MR,SPCC

Thickness:0.15mm - 0.50mm

Width: 600mm -1150mm

Temper: T1-T5

Annealing: BA & CA

Coil Inner Diameter: 508mm

Weight: 6-10 tons/coil 1~1.7 tons/sheets bundle

Passivation:311

Oil: DOS

Surface: Finish,bright,stone,matte,silver

Packing:

1、For sheets: plastic or waterproof paper, metallic cover and angles, steel strips,wooden pallet.

2、For Coils: plastic or waterproof paper,plastic protect plate,steel strips.

Both Prime and Second Quality Are Available!!!

- Q: What are the main innovations in tinplate manufacturing?

- One of the main innovations in tinplate manufacturing is the development of continuous annealing technology. This process allows for a more efficient and precise heat treatment of tinplate, resulting in improved mechanical properties and better coating adhesion. Additionally, the introduction of advanced coating systems, such as chromium-free passivation, has provided a more sustainable and environmentally friendly option for preserving the tinplate's surface and enhancing its corrosion resistance. Moreover, advancements in printing and decorative techniques have enabled manufacturers to create more visually appealing tinplate designs, catering to the evolving demands of consumers.

- Q: Why do tin tins rust easily when they are opened?

- The tinplate is of poor quality and the tin is not enough

- Q: What are the main factors influencing the demand for tinplate?

- The main factors influencing the demand for tinplate include the growth in the packaging industry, consumer preferences for canned goods, economic development in emerging markets, and environmental regulations promoting sustainable packaging.

- Q: What are the main applications of tinplate in the furniture industry?

- Tinplate is widely used in the furniture industry for various applications such as decorative elements, hardware components, and protective coatings. It provides a durable and corrosion-resistant surface finish, making it ideal for metal furniture pieces. Tinplate is also commonly used in the production of metal furniture frames, as it offers excellent strength and stability. Additionally, tinplate can be utilized for intricate designs and embossing, enhancing the aesthetic appeal of furniture items.

- Q: Can tinplate be used for packaging of sensitive electronic components?

- Yes, tinplate can be used for packaging of sensitive electronic components. Tinplate is known for its excellent barrier properties, providing protection against moisture, oxygen, and other external factors that could potentially damage electronic components. Additionally, tinplate is lightweight, easily formable, and cost-effective, making it an ideal choice for packaging sensitive electronic components.

- Q: How does tinplate perform in terms of stackability?

- Tinplate performs exceptionally well in terms of stackability. Its rigid and durable nature allows for easy stacking without compromising the structural integrity of the stack. Additionally, the smooth surface of tinplate ensures that stacked items do not shift or slide, further enhancing its stackability.

- Q: Can tinplate be used for solar panel applications?

- Yes, tinplate can be used for solar panel applications. Tinplate is often used as a protective coating for solar panels due to its corrosion resistance and ability to reflect sunlight. It acts as a barrier against moisture and environmental elements, ensuring the durability and longevity of the solar panels. Additionally, tinplate can enhance the overall efficiency of solar panels by reducing heat absorption and improving energy conversion.

- Q: What are the main factors influencing the competitiveness of tinplate manufacturers?

- The main factors influencing the competitiveness of tinplate manufacturers include price competitiveness, quality of products, technological advancements, production efficiency, supply chain management, customer satisfaction, and adherence to environmental and safety regulations. Additionally, factors such as market demand, brand reputation, innovation, and the ability to adapt to changing market trends also play a crucial role in determining the competitiveness of tinplate manufacturers.

- Q: How does tinplate perform in terms of insulation properties?

- Tinplate is not known for its insulation properties as it is a highly conductive material.

- Q: Can tinplate be used for automotive applications?

- Yes, tinplate can be used for automotive applications. Tinplate is a type of steel coated with a thin layer of tin, which provides excellent corrosion resistance. This makes it suitable for various automotive components such as fuel tanks, oil filters, and canisters. Tinplate's durability, strength, and ability to withstand extreme temperatures make it a reliable material for automotive applications.

Send your message to us

High Quality of Tinplate for Cookie Cans

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords