Prime C45 Carbon Steel Round Bar Used for Machinery Components

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Prime C45 Carbon Steel Round Bar Used for Machinery Components

Product Description of Prime C45 Carbon Steel Round Bar Used for Machinery Components

1. Steel grade: SAE1045, 45#, C45, S45C

2. Length: 6M-12M

3. Diameter: 16mm-300mm

4. Product range: round bar, flat bar, square bar

5. Technique: Hot rolled, forged, cold drawn

Specification of Prime C45 Carbon Steel Round Bar Used for Machinery Components

Material | C45 | 16-300mm | ||

Process | EAF + LF + VD + Forged + Heat Treatment (optional) | Length (mm) | Max 12m | |

Heat treatment | Normalized / Annealed / Quenched / tempered | Flat bar | Thickness(mm) | 8-500mm |

Delivery condition | Hot forged +Rough machined (black surface after Q/T)+ Turned (optional) | Width(mm) | 70-200mm | |

Test | Ultrasonic test according to SEP 1921-84 D/d | Length (mm) | Max 12m |

Chemical Composition of Prime C45 Carbon Steel Round Bar Used for Machinery Components

C | Si | Mn | Cr | Ni | Cu |

0.40~0.49 | 0.17~0.37 | 0.35~0.65 | ≤0.25 | ≤0.30 | ≤0.25 |

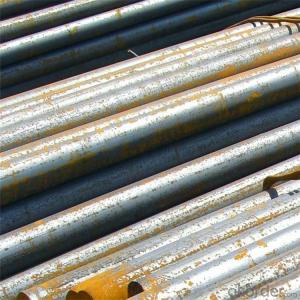

Photo Show of Prime C45 Carbon Steel Round Bar Used for Machinery Components

Packing and Delivery:

Packing in bundle package, or as customer's requirements.

Delivery Detail: 45 days after receiving the deposit.

Usage and Applications of Prime C45 Carbon Steel Round Bar Used for Machinery Components

1. Steel round bar is used in a large number of architectural and engineering structures. Or it can be used in construction of plants for the production of steel house frames, high-voltage transmission towers, bridges, vehicles, boilers, containers, ships, etc.

2. And we can use this kind of product on the performance of the mechanical parts if the demand is not very high.

3. Some special material steel round bar can be used for main shaft of steamer, hummer shank, with big section and supper force.

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

F A Q

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: What is the difference between a hot-rolled and a ground steel round bar?

- A hot-rolled steel round bar is produced by heating the steel billet to a high temperature and then rolling it into its desired shape and size. This process gives the bar a rough surface finish. On the other hand, a ground steel round bar is produced by further processing the hot-rolled bar through grinding, which removes any surface imperfections and provides a smooth and polished finish. In summary, the main difference between the two is the surface finish, with hot-rolled having a rougher texture and ground having a smoother and more refined appearance.

- Q: Can steel round bars be used for making tools?

- Yes, steel round bars can be used for making tools. Steel round bars are commonly used in tool making due to their strength, durability, and versatility. The high tensile strength of steel makes it suitable for withstanding heavy use and providing stability to tools. Additionally, steel round bars can be easily machined and shaped into various tool designs, allowing for the creation of different types of tools such as wrenches, chisels, punches, and hammers. Moreover, steel's resistance to corrosion ensures that tools made from steel round bars will have a longer lifespan. Overall, steel round bars are a popular choice in tool making due to their excellent mechanical properties and suitability for various applications.

- Q: Can steel round bars be used for making brake components?

- Yes, steel round bars can be used for making brake components. Steel is a common material used in the manufacturing of brake components due to its high strength, durability, and resistance to heat and corrosion. Steel round bars can be machined and formed into various shapes required for brake components such as brake rotors, brake caliper brackets, or brake pedal levers.

- Q: Can steel round bars be used in the manufacturing of conveyor systems?

- Yes, steel round bars can be used in the manufacturing of conveyor systems. Steel round bars are often used as the main structural component for conveyor systems due to their durability, strength, and ability to withstand heavy loads. They provide stability and support for the conveyor belt, rollers, and other components, making them an ideal choice for conveyor system construction.

- Q: How are steel round bars manufactured?

- Hot rolling is the method utilized to produce steel round bars. The process begins with heating a large steel billet in a furnace until it becomes soft and malleable. Subsequently, the billet is passed through a series of rollers, which compress and shape it into a round bar. The initial step in hot rolling is the roughing mill, where the billet is subjected to multiple sets of rollers to reduce its thickness and increase its length. This step ensures that the steel maintains a consistent temperature throughout. Following the roughing mill, the bar enters the finishing mill, where it undergoes further size reduction and acquires its final shape. The finishing mill typically comprises several sets of rollers that gradually decrease the bar's diameter while increasing its length. This process is repeated until the desired dimensions are attained. Throughout the rolling process, rigorous quality control measures are implemented to continuously monitor the steel round bar. Any imperfections or defects that arise are promptly identified and rectified to ensure the final product adheres to the required specifications. Once the bar reaches its final dimensions, it is cooled and cut to the desired length. The cooling process can be achieved through the use of air, water, or a combination of both. Subsequently, the bar is inspected for any surface defects and may undergo further processing if needed. In certain cases, additional treatments such as heat treatment or surface finishing may be employed to enhance the properties and appearance of the steel round bar. In conclusion, the manufacturing of steel round bars involves a combination of heating, rolling, cooling, and cutting processes. These procedures are meticulously executed to yield a superior product that fulfills the specific requirements of diverse industries.

- Q: Are steel round bars suitable for use in the aerospace industry?

- Yes, steel round bars are suitable for use in the aerospace industry. Steel offers high strength and durability, making it ideal for components and structures that require reliability and performance in demanding aerospace applications. Additionally, steel round bars can be customized to meet specific requirements, such as resistance to corrosion, high temperatures, and fatigue.

- Q: Are steel round bars used in the construction industry?

- Yes, steel round bars are commonly used in the construction industry. They are often used as structural elements, such as reinforcement in concrete structures, as well as in the fabrication of various components and fittings.

- Q: How do you calculate the weight of a steel round bar based on its density and dimensions?

- In order to determine the weight of a steel round bar, one must possess knowledge of its density and dimensions. The weight can be calculated using the formula W = V x D, where W represents weight, V represents volume, and D represents density. Firstly, it is necessary to ascertain the volume of the round bar. The volume of a cylinder can be calculated using the formula V = πr^2h, where V represents volume, π is a constant (approximately 3.14159), r represents the radius of the round bar, and h represents the height or length of the round bar. In the event that one possesses the diameter of the round bar instead of the radius, the radius can be determined by dividing the diameter by 2. Once the radius is determined, it can be substituted into the formula along with the height of the round bar to calculate the volume. Subsequently, knowledge of the density of the steel is required. The density of steel is typically measured in grams per cubic centimeter (g/cm^3) or kilograms per cubic meter (kg/m^3). It is imperative to ensure that the units for both density and volume are consistent. If the density is given in g/cm^3, the volume must be converted from cm^3 to m^3 by dividing it by 1,000,000. Finally, the weight can be calculated by multiplying the volume by the density. If the density is provided in kg/m^3, the weight will be in kilograms. If the density is provided in g/cm^3, the weight will be in grams. Conversion to other units can be achieved by utilizing appropriate conversion factors. It is crucial to verify all calculations and maintain consistency of units throughout the entire calculation process.

- Q: What are the different types of steel round bar surface treatments used in the automotive industry?

- In the automotive industry, the most common types of steel round bar surface treatments used are galvanization, electroplating, and powder coating. Galvanization involves coating the steel with a layer of zinc to protect it from corrosion. Electroplating is a process where a thin layer of another metal, such as chrome or nickel, is applied to the steel surface for enhanced aesthetics and protection. Powder coating, on the other hand, involves applying a dry powder to the steel surface and then curing it under high heat to create a durable and attractive finish. These surface treatments help improve the durability, appearance, and overall performance of steel round bars used in automotive applications.

- Q: What are the different types of steel round bar alloys for improved strength?

- There are several types of steel round bar alloys that provide improved strength, including carbon steel, alloy steel, stainless steel, and tool steel. Each of these alloys has different properties and compositions, making them suitable for various applications where enhanced strength is required.

Send your message to us

Prime C45 Carbon Steel Round Bar Used for Machinery Components

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords