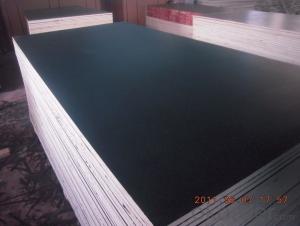

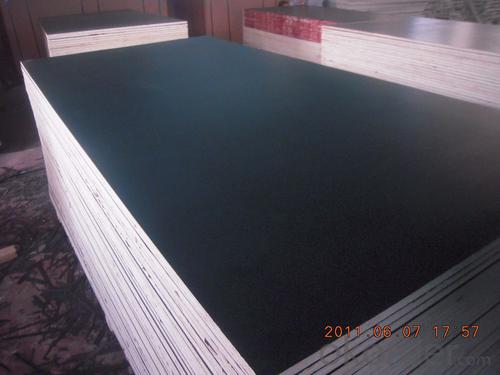

Price of 4 X 8 Brown/Black Film Faced Plywood Shuttering Plywood WBP Glue Construction Plywood

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 20000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specification:

Item name:Black/Brown Film Faced Plywood

Size:1220*2440/1250*2500

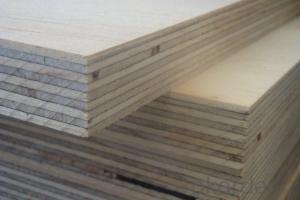

Core: poplar/hardwood/combi/birch

Glue: WBP, melamine, phenolic

Description:

| Marine plywood/Film Faced Plywood | ||

| Film | Brown film, Black film | |

| Core | Poplar, hardwood, pine and others | |

| Glue | WBP,Melamine,MR | |

| Size(mm) | 1220*2440, 1250*2500, or requested by customers | |

| Thickness(mm) | 6-27mm | |

| Density | >550-650g/CBM | |

| Moisture | 8-12% | |

| Modulus of Elasticity | >6000Mpa | |

| Modulus of rupture | >30Mpa | |

| Quantity | 20GP | 8 pallets/21M3 |

| 40GP | 16 pallets/42M3 | |

| 40HC | 18 Pallets/53M3 | |

| Min Order | 1*20 ft container | |

| Payment | T/T or L/C at sight | |

| Delivery time | Within 2 weeks after receiving deposit or Original L/C at sight | |

| Addition | Sample available | |

| film faced plywood pictures | ||

Features:

1. The face should be of high resistance to corrosion and moisture.

2. The face should be smooth and easy to take off from cement and easy to clean.

3. The core should be water resistant and won’t swell.

4. The core should be strong enough and won’t break.

5. The edge should be sealed and water proof.

Advantages of our film faced plywood

1. Above 18mm thickness film faced plywood , could be used 20 time at least

2. The inside each veneer is whole core

3. Each veneer is glued totally

4. Boiled for 10 hours , will not cracking

5. Twice hot press to strong joining capacity

6. Cold press again to strong joining capacity

7. 100% Dry

8. We have another glue making factory

FAQ

A. Quality :

With the skilled worker ,mature technology and ten years experience ,all our plywood are steady quality .

B. Price:

Due to the skilled worker ,mature technology and an experienced operating system , we can

quote you competitive price , so that you will have the price advantage to capture your market.

C.Service:

7*24hours , if any need, you can email or call us,we will do our best to meet your demand

D.Export experience:

Over ten years experience for exporting ,We are much familiar with

the export operation .

- Q: defects are divided into four grades

- It is generally judged by visualizing the allowable defects on the plywood. The grade depends on the permissible material defects, machining defects, and the requirements for splicing

- Q: What is the composition of the plywood?

- Glue plywood usually refers to the plywood or multi-layer board, that is, with the same thickness of two or more layers of veneer plus glue from high temperature suppression.

- Q: What are the further processing of plywood?

- plywood plywood through mechanical finishing or gluing, such as cutting, profiling sawing, hitting, drilling, milling and other processed plywood

- Q: How do I determine if plywood contains formaldehyde?

- Those who claim real real wood furniture, which often possession of plywood.

- Q: Contemporary plywood market development

- China's rapid economic growth has become a strong traction to promote the market demand for plywood; North China, East China and the middle and lower reaches of the Yangtze River area fast-growing high-yielding forest timber poured into the market

- Q: Wood board, plywood, MDF What is the difference

- Blockboard is the core board made of wood board stitching, the two surfaces for the sticky wood veneer solid plate. Veneer, also known as the table, below the board by the board of a board said plate.

- Q: Classification of plywood for construction

- if you want to make general indoor wood products, you can use E1 (or even E0) urea formaldehyde

- Q: What is the amount of construction works used for this plywood?

- Three types of plywood for moisture-resistant plywood, can be immersed in cold water for a short time, suitable for indoor use at room temperature. For furniture and general construction purposes;

- Q: Hard fiber board is also a density board

- the same texture direction. Adjacent two-layer veneer grain direction should be the same. The plywood should be the same tree.

- Q: What are the shortcomings of plywood

- A group of veneers are usually in the direction of adjacent layers of wood grain perpendicular to the formation of each other, usually its table and the inner plate symmetrically arranged in the center layer or plate on both sides

Send your message to us

Price of 4 X 8 Brown/Black Film Faced Plywood Shuttering Plywood WBP Glue Construction Plywood

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 20000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords