Presstressed Purline Beam Molding Machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Presstressed Purline Beam Molding Machine

1. Structure of Presstressed Purline Beam Molding Machine:

Presstressed Purline Beam Molding Machine is our special developed products as results of our engineers research, with which 60%steel material will be saved compared with traditional revolving die method .Efficiency can be improved 3 to 5 times compared with conical die method, these machine are easy for operation and convenient for maintenance, products from these machines are in good quality, smooth appearance and accurate in size.

2. Main Features of Presstressed Purline Beam Molding Machine:

• One machine can make one slab lower cost, high Wear-resistant, long service life.

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Provide consumers with regular visits

• Simple structure, easy operate, less wear parts

3. Presstressed Purline Beam Molding Machine Images:

4. Presstressed Purline Beam Molding Machine Specification:

Product name | Type | Productivity | Hole number |

Concrete purline machine | 60*120*140* | 1.3-1.5m/min | 4 |

Concrete purline machine | 60*130*150*4 | 1.3-1.5m/min | 4 |

Concrete purline machine | 60*140*160*4 | 1.3-1.5m/min | 4 |

Concrete purline machine | 70*150*170*2 | 1.3-1.5m/min | 2 |

Concrete purline machine | 80*160*180*2 | 1.3-1.5m/min | 2 |

Concrete purline machine | 60*110*130*4 | 1.3-1.5m/min | 4 |

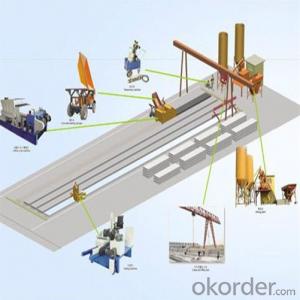

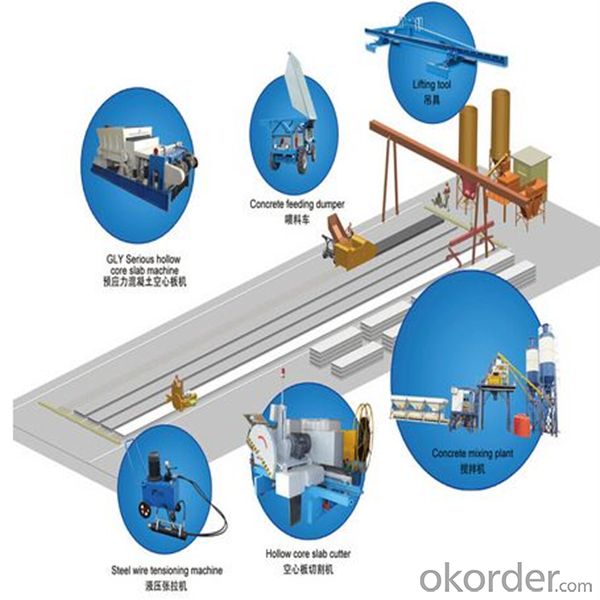

Production Line Layout

Production Flow Chart

Certificates

5. Packing & Delivery

• Wire cables are used for fastening the machine on the trailer or inside the container.

• Machine covered with plastic film.

• Machines can be packed in tarpaulin or wooden case according to customer’s needs.

6. Customers from All Over The World

7. Why choose us:

• 30 years manufacturing experience.

• Constitutor of the <Chinese Prestressed Concrete Hollow Core Slab Standard>.

• More than 10 patents.

• Passed ISO9001:2000 quality system certificate.

• More than 10 types of machine and over 100 models for choose.

• Supply complete set of technology and equipment solution.

• We can design and manufacture all kinds of concrete forming equipment according to customers' demands. Meanwhile we can even more provide our customers a complete set of technology and solution for all producing flow.

8. Our Service:

• We supply the technical supporting all the time.

• We supply one year warranty for whole machine.

• We supply free quick wear parts.

• We supply low charge continue maintenance when warranty is expired.

• We supply free training to end-users

- Q: I'm in a tropical country, and heck, my whole life living here. I haven't experienced this kind of heat!I'm just a student, and because of that, I have no money to buy an ice cream maker.How can I make ice cream without a ice cream maker?

- go to the shops

- Q: What is the best way to invent something? Like and industrial piece of machinery.?

- Have imagination, patience and lots of money.

- Q: If the machinery that accomplishes X-chromosome dosage compensation in humans was defective (e.g., 1 protein was mutant), what do you expect the consequences would be? Choose one. a) no consequences b) XX embryos would not be viable c) XY embryos would not be viable d) both XX and XY embryos would not be viable

- B

- Q: I sold $30,000 in business assets(machinery,equipment)this year, how would I claim that on my taxes. would it be considered quot;other incomequot; or quot;capital gainquot;?

- I am sure you have depreciated those assets over the years since you put in service, so what you do is: You need dispose them, which means enter sale date, sale price, sales expenses (if you have any) and adjusted basis (cost - accumulated depreciation- current year's depreciation= usually computer does this calculation for you) then you will know if you have gain or loss. You need do this by accessing your depreciation worksheet for each asset. If you haven't depreciated them for over the years, you probably should report those on the Form 4797(not capital assets form Schedule D)- sale of business assets. OK?

- Q: i've been working out on my arms for 6 months now but can't seem to get any results on the sides of my upper arms.i'm not really skinny,i'm avarage body build but i have skinny arms.i can grow muscle on front and back of my arms,but not on the sides.what are some good exercises,exercise machinery or techniques i can use to target these areas?(and sorry i don't know the technical names for these muscles in the arm)

- mattress of nails by utilising alice cooper sledgehammer by utilising peter gabriel huge undesirable John by utilising jimmy dean, confident, the sausage guy. LOL The God that failed by utilising metallica cock the hammer by utilising cyprus hill

- Q: maintenance for the 1st year is 150, and increases by 150 every year until the fourth year. if the interest is 85% per year find the equivalent uniform annual maintenance cost.

- Get a differnt credit card. 85% is way too high. . MWAP

- Q: would these include non motorized equipment used for processing?

- farm machinery, mechanical devices, including tractors and implements, used in farming to save labour. Farm machines include a great variety of devices with a wide range of complexity: from simple hand-held implements used since prehistoric times to the complex harvesters of modern mechanized agriculture.

- Q: Why might the machinery of war, set in motion by the assassination of Archduke Ferdinand, have been difficul?

- one major reason was the complex net of political and military alliances . the actual antagonists. Austria and Hungry drew in all of Europe Wilson and America wisely wanted to stay out the British tricked USA with the 'zimmerman telegram' and the sinking of the civilian ship the Lusitania, which was carrying forbidden military suppies ( ammunition) to Britain. About the same time a relevolution was taking place in Russia, communists were involved and the West was terrified of anything like communism. America actually sent troops to fight in Russia AFTER WW I.

- Q: What are the main considerations when choosing mechanical parts?

- The impact of ambient temperature, changes in ambient temperature will affect the expansion and contraction of parts; parts of the surface quality requirements and corrosion requirements; cost factors;

- Q: this is according to marx, i think its to do with how machinery changed society from primitive to industrial, im not sure tho, any help would be gratefully appreciatedthanks

- Machines okorder

Send your message to us

Presstressed Purline Beam Molding Machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords