Prefab Decks WPC House Decking Outdoor Use

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Prefab Decks:

A safe, environmentally responsible alternative to traditional decks, conserving energy and resources. Not only does this save your time over the maintenance, but it will save you money as well.

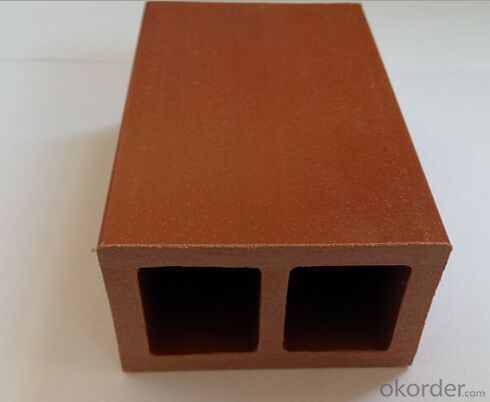

Composition of Prefab Decks:

30% HDPE+60% bamboo/wood fiber+10% Chemical additives.

Advantage of Prefab Decks:

· Maximum length: 6m

· UV resistance, durable

· Safe, environmentally responsible alternative to traditional decks, conserving energy and resources

· Low maintenance

· 100% recyclable

· Saves forest resources

· With look of natural wood but no timber problems

· Moisture/water-resistant

· No rotten, proven under salt water condition

· Barefoot friendly, anti-slip, no cracking and warping

· Requires no painting and glue

· Weather-resistant

· Termites, insects and moldy-proof

· Easy to install and clean

· Available in various colors

· Can be used in Temperature: -40 to +60°C

Installation of Prefab Decks:

Correct installation needs your high attention!

1 Always leave space (5-7mm) between 2 boards, or between board and wall.

2 Where there are 2 board ends meet, put 2 pcs of keels under each board end.

3 Keep the space of 2 keels at 25-750px.

4 Do not use glue to install.

5 Do not use our product where is always wet and sunless.

Other Information of Prefab Decks:

HS code: 3918909000

Time for production(1x20fcl): 15 days

Warranty: 10 years.

Certificate: CE, ISO

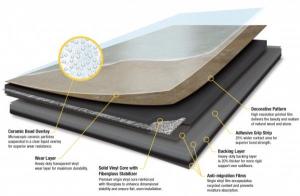

- Q: What's the function of the plastic film under the wood floor?

- Prevent moisture and moisture, so as not to the floor because of water seepage to the deformation of the wooden floor.

- Q: Plastic floor can be used indoors

- In our minds the plastic floor are generally used outdoors, such as the use of polyurethane (also called PU) made of PU silicon PU stadium and stadium, and our common stadium plastic runway and so on, because the plastic floor will release some harmful substances, it is generally not used for indoor sports venues. But there is also a material PVC in our plastic floor, which is specially designed for indoor use.

- Q: A floor tile, with a knife cut appear skin, turned out to be plastic, this is what floor tiles

- This should be a kind of elastic floor, probably PVC floor, also known as stone plastic flooring, more types, the general price of 30-50 yuan a square meter, the more than and 100 floor price you should be very clear, from tens to hundreds of square meters have

- Q: The home is all ceramic tile or plastic floor

- Unwanted。 In winter, you can carpet in the bedroom. I hope my answer can help you

- Q: With this plastic floor mat bed can not? Will not have any impact on people

- This is used in conjunction with the infant floor, which belongs to (XPS) extruded plate and the like, the density is better. Better than foam board (EPS) slightly better, it is best not to shop on the bed as well......

- Q: Material advantages of plastic flooring

- According to its basic raw materials can be divided into polyvinyl chloride (PVC) plastic, polyethylene (.PE) plastic and polypropylene (PP) plastics, etc..

- Q: Dog feces in the plastic floor on how to clean, 84, washing powder, detergent are used, or brush off, how to do? What cleaning

- This is your sheet plastic floor, the sheet surface layer without UV treatment, suggested the use of plastic floor material, plastic floor can directly clean water, plastic flooring selection coil special PVC glue, stairs, wall with adhesive

- Q: What is the name of the plastic floor on the supermarket, where is it?

- Plastic flooring selection coil special PVC glue, stairs, wall with adhesive

- Q: Is it the heat of the plastic sheeting does not affect it? Do you really have a moisture-proof effect?

- There are a small number of plastic sheeting practices, the effect is not very good.

- Q: Home decoration house, because there is no time, all to the decoration company, now just installed, found the decoration company to use in the bedroom floor is only 0.7 cm thick, and skirting the bedroom are plastic, and the rest of the baseboard and tried hard to break. I would like to ask you how long this line can be used? Need to be removed and replaced with good quality? Will be removed when the...

- Just let him change it for you. The truth is the same, but the baseboard, do not have too much to worry about, plastic skirting is allowed gb.

Send your message to us

Prefab Decks WPC House Decking Outdoor Use

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords