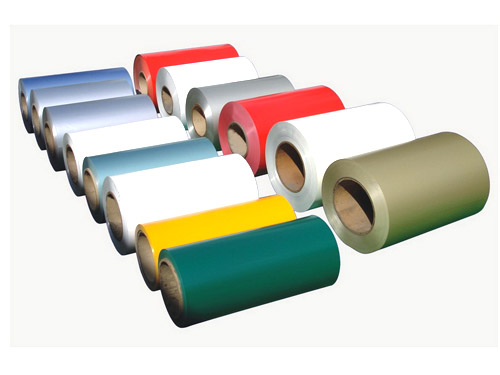

PRE-PAINTED STEEL COIL

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Prepainted galvanized steel coil JIS G3312

Grade: SGCC SGLCC

Annual output: 100000MT

Surface: glossy 60+, matt,etc

Prepainted galvanized steel coil PPGI as follows:

1) Quality standard of Prepainted galvanized steel PPGI: JIS G3312 CGCC & CGLCC

2) Grade of Prepainted galvanized steel PPGI: CGCC and CGLCC

3) Hardness of Prepainted galvanized steel PPGI: Both soft and hard quality are available

4) Surface finish of Prepainted galvanized steel PPGI: with or without protect film

5) Thickness of Prepainted galvanized steel PPGI: 0.14-1.20 mm

6) Width of Prepainted galvanized steel PPGI: 914mm, 1000mm, 1220mm and 1250mm, thickness 600-1250mm is available

7) Finish by coil or sheet for Prepainted galvanized steel PPGI: Both sheet and coil are available

8) Zinc coating of Prepainted galvanized steel PPGI: 60-275G/M2, both sides

9) Paint thickness for top side of Prepainted galvanized steel PPGI: 5 micron primer + (10-20) microns modified polyester, any RAL color code.

10) Paint thickness for back side of Prepainted galvanized steel PPGI: (5-10) microns Epoxy

11) Weight per Prepainted galvanized steel PPGI: 4-6 tons, also can be upon customer's requirements

12) Max loading weight in one 20ft container for Prepainted galvanized steel PPGI: 25 tons generally

13) MOQ of Prepainted galvanized steel PPGI: 25 tons for each item;

14) Actual shipping quantity of Prepainted galvanized steel PPGI: More or less 10% generally;

15) Delivery time for Prepainted galvanized steel PPGI: 15 days ganerally.

16) Applications of Prepainted galvanized steel PPGI: Widely used for roofs, outer walls, ovens, explosive-proof steel, electrically controlled cabinets, and industrial freezers in the residential and industrial buildings

Standard | JIS G3312 CGCC |

Valid thickness | 0.20~1.10mm |

Coil width | 600~1250mm |

Coil ID | 508mm & 610mm |

Coil weight | 3~5 tons |

Zinc coating | 80~275 g/m2 |

Thickness of top paint | 15~25 microns |

Thickness of reverse paint | 5~7 microns |

Color | any RAL code |

Package | vertical, eye to sky & horizontal |

MOQ | 25 tons |

- Q: What are some characteristics of steel.

- Characteristics Of Steel Hardening. - The characteristic difference between steel and pure wrought iron is as follows: - When steel is raised to a red heat and then suddenly cooled, it becomes hard and brittle. This process, which is known as hardening, has no effect upon pure wrought iron. Tempering is a characteristic of steel which distinguishes it from cast iron. If steel has been hardened by being heated and suddenly cooled, as above described, it may be softened again by applying a lower degree of heat and again cooling. This is known as tempering. Cast iron, on the contrary, though it is hardened by the first process, cannot be softened by the second. When a bar of steel is struck it gives out a sharp metallic ring, quite different from the sound produced by striking wrought iron. Other characteristics of steel are its great elasticity and its retention of magnetism.

- Q: How are steel coils protected against scratches and damage?

- Steel coils are protected against scratches and damage through a variety of methods. One common method is the application of a protective coating or film on the surface of the coils. This coating acts as a barrier, preventing direct contact between the steel surface and any potential sources of scratches or damage. The protective coating can be made of materials like polyethylene, PVC, or other types of plastic that are resistant to abrasion and impact. Additionally, steel coils are often wrapped or packaged using materials such as paper, cardboard, or plastic. This wrapping provides an extra layer of protection against scratches and damage during storage, transportation, and handling. The wrapping material acts as a cushion, absorbing any potential impacts or friction that could lead to scratches. Furthermore, steel coils may be stored and transported in specially designed containers or pallets that are equipped with features to minimize the risk of damage. For instance, these containers or pallets may have padded interiors, secure fastenings, or dividers that keep the coils in place and prevent them from rubbing against each other. In some cases, steel coils are also stored or transported in a controlled environment to minimize the risk of damage. This can include temperature-controlled warehouses or shipping containers that help to prevent the formation of moisture, which can lead to corrosion or other types of damage. Overall, a combination of protective coatings, wrapping materials, specialized containers, and controlled environments is employed to ensure that steel coils are adequately protected against scratches and damage throughout their lifecycle.

- Q: What are the different types of steel alloys used in coils?

- There are various types of steel alloys used in coils, including carbon steel, stainless steel, galvanized steel, and electrical steel.

- Q: I am reading the book The Cure For All Advanced Cancers by Hulda Regehr Clark.She writes for example: cancer can be caused by exposure to heavy metals, like nickel and chromium from stainless steel cookware. Stainless steel cookware releases chromium and nickel, two of the most carcinogenic metals.Are there any studies done measuring how much nickel and cadmium can be released from the regular use of stainless steel cookware?Is this a commonly accepted opinion that use of stainless steel cookware is dangerous?If not stainless steel, what kind of cookware to use? I heard that non-stick cookware also releases some harmful chemicals.

- perfluorooctanoic acid is a chemical used to make nonstick cookware. It has been shown to cause cancer in lab animals. The epa has asked companies that use that chemical to phase it out of the cookware, just in case. But it has not been shown to cause cancer in humans. Stainless is not known to cause any type of health problems. Cast iron is healthier and anodized aluminum is great too.

- Q: What is the minimum diameter of a steel coil?

- The minimum diameter of a steel coil depends on various factors such as the thickness of the steel, the type of coil, and the intended use. However, it is generally recommended to have a minimum diameter of around 3 times the thickness of the steel for optimal performance and to prevent damage to the coil during handling and transportation.

- Q: They are showing on tv a special on how the new World Trade Center, building 1, is being built. Focusing on the steel and the guys fitting everything together.Where do builders go to buy all that steel framing? We do not build really tall buildings where I live so most of the steel is cut and welded on the job site. At World Trade Center 1, they seem to get the steel on trucks; already cut and welded.

- The steel is all custom fabricated in what are called structural steel fabrication shops. Each Building is designed by architects then the frame is designed by engineers to support whatever load is being applied to the building. After the engineering is done it goes out for a bid package where a fab shop estimates how much to charge for the fabrication of the steel and the erection of the steel. Once a company wins the bid, it then has to design how the steel will connect with one another and have it approved by an engineering firm to assure the connections are strong enough. Once all of that happens the fab shop orders raw steel beams and angle iron and steel plate at stock lengths. Beams are then cut into the right length and holes drilled in the proper places. The beam is then marked with a number that tells the erectors where it goes. The steel is then shipped out in batches to the construction site where it is unloaded and shook out into an organized place to grab them with a crane. They are then put together like a toy model, there are instructions that say what beam goes where and what size bolt to use. The welding you see being done is on really critical moments that need extra strength. That is about how it goes in a nutshell. It is a bit more complicated than that but it gives you an idea.

- Q: hello, just wondering if there is such a thing as a stainless steel coating for my aluminum muffler prior to installation. Yes, i suppose you can say that im cutting corners, but my current finances wont allow me to pay full price for a stainless steel one, thnx

- No stainless steel, I'm afraid, but there is an aerosol spray that a lot of welders use . It's a galvanic spray compound to coat weld joints to keep from rusting. It's silver in color, and my add a little 'pop' that it seems you are looking for. Also heat tolerant, and can be re-applied. Most welding supply stores carry this item, and look to pay around $12 a can. Good luck!

- Q: How are steel coils used in the production of automotive body panels?

- Steel coils are used in the production of automotive body panels by being processed and shaped into the desired form through techniques like stamping, cutting, and bending. These coils provide the necessary strength and durability required for the structural integrity of the body panels, ensuring the safety and performance of the vehicle.

- Q: What are the common welding methods used for steel coils?

- The common welding methods used for steel coils include shielded metal arc welding (SMAW), gas metal arc welding (GMAW), flux-cored arc welding (FCAW), and submerged arc welding (SAW).

- Q: What is the average lead time for receiving replacement steel coils?

- The average lead time for receiving replacement steel coils can vary depending on various factors such as the supplier, location, and specific requirements. It is recommended to contact the supplier directly for an accurate estimation of the lead time.

Send your message to us

PRE-PAINTED STEEL COIL

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords