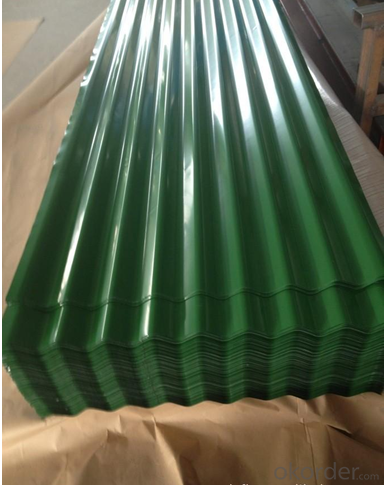

Pre-Painted Steel Coil Thickness 0.3mm-2mm Width 900mm-1250mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

cold rolled strips

1. width: 19-1500mm

2. thickness :0.2-3.0m,2.0-13.5mm

3.zinc coating:z60-z275

4.GB,JIS,ASTM,DIN,EN

NAME | PPGI | GALVANIZED | GALVALUME/ALUZINC |

CERTIFICATE | ISO9001:2008 | ||

| EN10142 | ASTM A653 | ASTM A792 |

| CGCC | SS GRADE33-80 | GRADE33-80 |

MODEL NO | 0.16MM-1.5MM*1250MM OR UNDER | (0.12-1.5)*1250MM OR UNDER | 0.16MM-1.5MM*1250MM OR UNDER |

| Steel coil | Steel coil | Steel coil |

| Hot rolled-cold rolled | Hot rolled-cold rolled | Hot rolled-cold rolled |

SURFACE | Mini/regular/big/zero spangle, | Mini/regular/big/zero spangle, | |

APPLICATION | Structural use ,roofing, commercial use, household appliance, industry, family | ||

SPECIAL | Wear resistant steel, high- strength - steel plate | ||

Applications:

Pre-painted steel metal products are used in a vast array of applications including:

1.construction industry

2. household appliances

3.automotive

4.industrial applications

5.packaging

FAQ

What is the validity of your quotation?

Normally 2 days.

- Q: How do steel coils impact the environment?

- Steel coils can have both positive and negative impacts on the environment. On one hand, the production of steel coils requires significant amounts of energy and emits greenhouse gases, contributing to climate change. Additionally, the extraction of raw materials for steel production can lead to deforestation and habitat destruction. On the other hand, steel is highly recyclable, reducing the need for new steel production and saving energy and resources. Proper waste management and recycling practices can mitigate the negative environmental impacts of steel coils.

- Q: Are steel coils affected by magnetic fields?

- Yes, steel coils can be affected by magnetic fields. Steel is a ferromagnetic material, which means it can be magnetized or attracted to magnets. When a magnetic field is applied to a steel coil, it can induce a magnetic field within the coil, causing the coil to become magnetized. This can have several effects depending on the strength and duration of the magnetic field. If the magnetic field is strong and the coil is exposed to it for a significant amount of time, it can cause the steel coil to retain some magnetism even after the magnetic field is removed. This can be problematic in certain applications where a non-magnetic material is required, as the magnetized steel coil may attract or interfere with other nearby objects. On the other hand, if the magnetic field is rapidly changing or fluctuating, it can induce electrical currents within the steel coil through electromagnetic induction. These induced currents, known as eddy currents, can generate heat within the coil, leading to energy losses and potential damage to the coil. Therefore, it is important to consider the effects of magnetic fields on steel coils in various applications. Protective measures such as shielding or demagnetizing processes may be necessary to minimize the impact of magnetic fields on steel coils when required.

- Q: 420 440 1045 or 1065 ive bought knifes with these steel grades and i want to know which one is better.

- SAE 440 is the best. Classified as high grade cutlery steel. There are various grades of 440: A, B, C, and F. 440 A is the most stain resistant while 440 C has the most carbon and can achieve the highest hardness (Best edge Retention). SAE 440 Chemistry: 16 - 18% Chromium, 0.60 - 1.2% Carbon, 0.75% Molybdenum. SAE 420 is pretty good. Classified as cutlery steel, it is a stain resistant grade but has less chromium and significantly less carbon than SAE 440. SAE 420 Chemistry: 12 - 14% Chromium, 0.15% Carbon (min), 0 Molybdenum Chromium is what makes the steel corrosion resistant. It also adds toughness. Molybdenum adds extra corrosion resistance and adds hardenability. So you can see by chemical components that 440 is highest quality although that also means more cost. 1045 and 1065 are low quality steels and you should probably never use them for a knife. The 1 indicates plain carbon steel with little other alloying elements. The last two digits indicate how much carbon is in the steel. 1045 has 0.45% carbon, mid-range hardenability. 1065 has 0.65% carbon, high hardenability. So if I had to choose I would choose 1065 over 1045 but the difference isn't that noticeable. Everything I said here assumes they have all had the optimum Quench and Temper heat-treatment for their chemistry grade.

- Q: How are steel coils used in the production of infrastructure materials?

- Steel coils are commonly used in the production of infrastructure materials due to their strength and versatility. These coils are often transformed into various forms such as beams, plates, or pipes, which are then used in the construction of bridges, buildings, roads, and other vital infrastructure. The malleability and durability of steel make it an ideal material for withstanding heavy loads and harsh environmental conditions, ensuring the longevity and stability of the infrastructure.

- Q: How are steel coils inspected for camber using laser profiling?

- The inspection of steel coils for camber involves the use of laser profiling, a measurement technique that does not require physical contact. Laser profiling works by emitting a laser beam onto the surface of the steel coil, creating a detailed profile of its surface. To detect camber, the laser profiling system scans the entire length and width of the coil, capturing data points at regular intervals. These data points are then analyzed to determine the deviation from a straight line, indicating the presence of camber. During the inspection process, the measured profile of the steel coil is compared to a reference profile, which represents an ideal or straight surface. The deviation between the measured profile and the reference profile is calculated, and if it exceeds a predetermined threshold, the coil is flagged as having camber. The use of laser profiling offers several advantages for camber inspection of steel coils. Firstly, it eliminates the need for physical contact, reducing the risk of damage. Additionally, laser profiling is highly accurate, capable of detecting even small deviations in the coil's surface. This ensures reliable detection of camber, allowing for necessary corrective actions to be taken. Overall, laser profiling is an efficient and accurate method for inspecting steel coils for camber. It enables manufacturers to maintain high-quality standards and deliver reliable products to customers.

- Q: This needs to be in a percentage by mass. Could you please also reference where this info has come from. Thanks.

- pl. be specific about the type of steel: (Steel is a metal alloy whose major component is iron, with carbon content between 0.02% and 1.7% by weight. Carbon is the most cost effective alloying material for iron, but many other alloying elements are also used.[1] Carbon and other elements act as a hardening agent, preventing dislocations in the iron atom crystal lattice from sliding past one another. Varying the amount of alloying elements and their distribution in the steel controls qualities such as the hardness, elasticity, ductility, and tensile strength of the resulting steel. Steel with increased carbon content can be made harder and stronger than iron, but is also more brittle. The maximum solubility of carbon in iron is 1.7% by weight, occurring at 1130° Celsius; higher concentrations of carbon or lower temperatures will produce cementite which will reduce the material's strength. Alloys with higher carbon content than this are known as cast iron because of their lower melting point.[1] Steel is also to be distinguished from wrought iron with little or no carbon, usually less than 0.035%. It is common today to talk about 'the iron and steel industry' as if it were a single thing; it is today, but historically they were separate products. Currently there are several classes of steels in which carbon is replaced with other alloying materials, and carbon, if present, is undesired. A more recent definition is that steels are iron-based alloys that can be plastically formed (pounded, rolled, etc.). Iron alloy phases : Austenite (γ-iron; hard) Bainite Martensite Cementite (iron carbide; Fe3C) Ferrite (α-iron; soft) Pearlite (88% ferrite, 12% cementite) Types of Steel : Plain-carbon steel (up to 2.1% carbon) Stainless steel (alloy with chromium) HSLA steel (high strength low alloy) Tool steel (very hard; heat-treated) Other Iron-based materials : Cast iron (2.1% carbon) Wrought iron (almost no carbon) Ductile iron)

- Q: Which type is better and give reasons why... I making a team of either Dark or Steel :D Thankyou

- This Site Might Help You. RE: Steel vs. Dark Pokemon? Which type is better and give reasons why... I making a team of either Dark or Steel :D Thankyou

- Q: and what type of metal is steel?

- From the steel store. ;) Steel is an alloy consisting mostly of iron, with a carbon content between 0.2% and 2.14% by weight (C:110–10Fe), depending on grade. Carbon is the most cost-effective alloying material for iron, but various other alloying elements are used such as manganese, chromium, vanadium, and tungsten.

- Q: How are steel coils used in the production of furniture components?

- Steel coils are commonly used in the production of furniture components due to their strength, durability, and versatility. These coils, which are made from high-quality steel, are first uncoiled and then fed into a machine called a stamping press. The stamping press uses a die to shape and cut the steel coil into various components required for furniture production, such as chair frames, table legs, or brackets. The use of steel coils allows for the mass production of furniture components with consistent dimensions and high precision. The strength of steel ensures that the components can withstand heavy loads and provide stability to the furniture. Additionally, steel coils can be easily formed into different shapes and sizes, enabling the production of a wide variety of furniture designs. Moreover, steel coils are often coated or treated with protective layers such as paints or galvanization to enhance their resistance to corrosion, moisture, and wear. This ensures that the furniture components have a longer lifespan and maintain their aesthetic appeal over time. In summary, steel coils play a crucial role in the production of furniture components by providing strength, durability, and versatility. They enable the mass production of precise and consistent components, and their protective coatings ensure the longevity and quality of the final furniture products.

- Q: How are steel coils used in the manufacturing of intake manifolds?

- Steel coils are typically used in the manufacturing of intake manifolds as the primary material for forming the manifold's structure. These coils are shaped and cut into specific dimensions to create the necessary components, such as runners and plenums, which help regulate the flow of air and fuel mixture into the engine. The steel coils are often subjected to additional processes, including welding, machining, and surface treatments, to ensure the final intake manifold meets the required specifications and performance standards.

Send your message to us

Pre-Painted Steel Coil Thickness 0.3mm-2mm Width 900mm-1250mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords