Pre-painted Galvanized/Al uzinc Steel Sheet Coil with Prime Quality and Lowest Price bluee

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Pre-Painted Galvanized/Aluzinc Steel Coil Description:

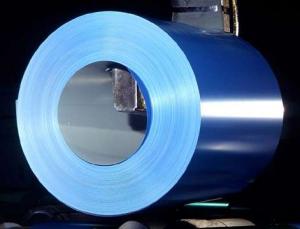

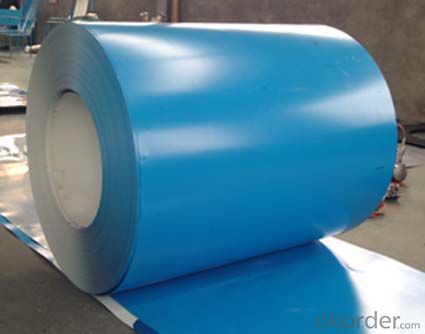

3.Detail Images of Pre-Painted Galvanized Steel Coil

4.Quick Details of the Pre-Painted Galvanized/Aluzinc Steel Coil

Standard | ASTM ,EN,JIS | Grade: | CS,DX51D+Z,CGCC | Thickness | 0.16mm-1.5mm |

Place of Origin | China(Mainland) | Brand Name | Type | Steel Coil | |

Technique | Galvanized/Aluzinc | Surface | Coated | Application | Roof panel |

Width | 900mm-1250mm | Length | Coils | Zinc Coating | 30g/m2-275g/m2 |

3) APPLICATION OF PPGI/PPGL (Prepainted Galvanized/GalvalumeSteel Coils)

Construction | Outside | Workshop, agricultural warehouse, residential precast unit, corrugated roof, roller shutter door, rainwater drainage pipe, retailer booth |

Inside | Door, doorcase, light steel roof structure, folding screen, elevator, stairway, vent gutter | |

Electrical appliance | Refrigerator, washer, switch cabinet, instrument cabinet, air conditioning, micro-wave oven, bread maker | |

Furniture | Central heating slice, lampshade, chifforobe, desk, bed, locker, bookshelf | |

Carrying trade | Exterior decoration of auto and train, clapboard, container, isolation lairage, isolation board | |

5.FAQ

1. What’s the application of this product?

surface sheet of balcony, frame of window

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil

• Superior workability

• High strength

• Good visual

- Q: How are steel coils inspected for mechanical properties?

- Steel coils are inspected for mechanical properties through a combination of destructive and non-destructive testing methods. Destructive methods involve conducting tensile, hardness, and impact tests on samples taken from the coils. Non-destructive methods, such as ultrasonic or magnetic particle testing, are also employed to detect surface and internal defects without damaging the coils. These inspections ensure that the steel coils meet the required mechanical specifications for their intended applications.

- Q: What is the maximum width of galvanized steel strip, please? The galvanized coat is 275, and how long is one coil?

- As far as I know, the galvanized rolls of WISCO are wider in width than other domestic steel mills, and can produce 2080 wide steel coils.

- Q: How are steel coils protected during transportation?

- Steel coils are kept safe and free from harm during transport through a range of precautionary measures. One widely used technique involves utilizing top-notch packaging materials like heavy-duty plastic wrap or waterproof paper. These materials form a protective shield against external factors such as moisture, dust, and debris. Moreover, steel coils are typically placed on wooden pallets or skids to elevate them from the ground and prevent direct contact with surfaces that may cause scratches or dents. To provide further protection, the coils are securely fastened to the pallets using strong, corrosion-resistant metal strapping or bands. This ensures that the coils remain in position and do not shift or move during transport, significantly reducing the risk of damage. Additionally, specialized equipment like coil cradles, coil racks, or coil bunks are used to load and secure the steel coils onto flatbed trailers or shipping containers. These devices are specifically designed to firmly hold the coils in place and evenly distribute their weight, preventing any stress or strain during transit. Apart from physical safeguards, steel coils may also undergo various surface treatments before being transported to prevent corrosion. This may involve applying a protective coating or oiling the coils to create a barrier between the steel and the surrounding environment. This process is particularly important when the coils are exposed to adverse weather conditions or long shipping durations, as it helps to prevent rust or other forms of corrosion. In conclusion, a combination of appropriate packaging, secure fastening, and proper loading techniques are employed to ensure the safety of steel coils during transportation. These measures guarantee that the coils arrive at their destination without significant damage.

- Q: How are steel coils used in the production of electrical conduits?

- Steel coils are used in the production of electrical conduits as they serve as the raw material for manufacturing these conduits. The steel coils are processed and shaped into cylindrical tubes, which are then used to protect and enclose electrical wires, ensuring safe and efficient transmission of electricity.

- Q: I'm trying to put together a small structure using galvanized steel electrical conduit (3/4) and I can't seem to find a T-junction conduit coupler anywhere. I'm wondering if I could weld the tubing together, but I'm not sure if I can weld galvanized steel. Also, if I can weld them, is there any special technique that I need to use outside of regular acetelene/oxygen torch and solder?

- Can You Weld Galvanized Steel

- Q: Can steel coils be coated with RFID technology?

- Yes, steel coils can be coated with RFID technology. The RFID tags can be securely attached to the surface of the steel coils, allowing for easy tracking, inventory management, and supply chain visibility.

- Q: days. Use your knowledge of the corrosion of steel and aluminum to predict how they would look different after a week exposed to rainy weather. Explain your prediction.

- I'd expect appearance of reddish dots or stains of rust on steel, while aluminium should stay virtually unchanged. Explanation: Both materials oxidize in natural environment because of atmospheric moist, but in very different ways. As for steel, oxidation begins as reddish dots of rust which grow and become stains. Oxidation then progresses in depth causing decay of material, compromising its strength and structural integrity.

- Q: What are the common surface treatments for galvanized steel coils?

- Galvanized steel coils can undergo various surface treatments to improve their corrosion resistance and appearance. Passivation is one such treatment, where a protective material like zinc phosphate or chromate is applied to create a barrier against moisture and atmospheric elements. This also enhances the adhesion of subsequent coatings or paints. Another treatment is chromate coating, which involves applying a thin layer of chromate to the steel surface. This provides extra protection against corrosion and enhances the steel's appearance. Chromate coatings can be clear or colored, depending on the desired aesthetic. Oiling is a common treatment that involves applying a thin layer of oil to prevent rust and corrosion during storage and transportation. It also offers temporary protection against moisture and other environmental factors until the steel is further processed or used. These surface treatments are widely used to improve the performance, durability, and appearance of galvanized steel coils, ensuring they can withstand harsh conditions and maintain their quality over time.

- Q: How do steel coils contribute to the HVACR industry?

- Steel coils play a crucial role in the HVACR (Heating, Ventilation, Air Conditioning, and Refrigeration) industry by serving as a primary component in various applications. These coils are typically made from a durable and corrosion-resistant material, such as stainless steel or galvanized steel, which ensures their longevity in demanding HVACR environments. One of the most common uses of steel coils in the HVACR industry is in air conditioning systems. These coils are responsible for transferring heat between the refrigerant and the surrounding air. The coils, often referred to as evaporator coils, absorb heat from the indoor air, cooling it down and removing moisture. They then release the heat outside through a condenser coil, allowing for efficient cooling and dehumidification of the air. Steel coils are also utilized in heat exchangers, which are vital components in HVACR systems. Heat exchangers transfer thermal energy between two fluids, allowing for efficient heating or cooling. Steel coils, often in the form of finned tubes, provide a large surface area for heat transfer and help enhance the overall efficiency of the system. Furthermore, steel coils are extensively used in the construction of ductwork, which is the network of channels that distribute conditioned air throughout a building. These coils are formed into various shapes and sizes to fit specific ductwork designs, ensuring optimal airflow and temperature control. Additionally, the durability and strength of steel coils make them suitable for withstanding the pressure and forces exerted by airflows in duct systems. In refrigeration systems, steel coils are integral to the process of transferring heat out of an enclosed space, such as a refrigerator or freezer. The coils, often referred to as condenser coils, release heat from the refrigerant as it changes from a high-pressure gas to a high-pressure liquid. This allows for the cooling and preservation of perishable goods, making steel coils essential in the food service and cold storage industries. Overall, steel coils contribute significantly to the HVACR industry by enabling efficient heat transfer, optimal temperature control, and reliable operation of various HVACR systems. Their durability, corrosion resistance, and versatility make them a crucial component in providing comfortable and controlled environments in residential, commercial, and industrial settings.

- Q: Does Steel Cut Oatmeal have the same health benefits as Old Fashioned Oatmeal? What is the difference in processing?

- Steel Cut Oats Steel-cut oats are whole oat kernels cut into small chunks rather than being smashed flat as in oatmeal. This gives the oats more of a chew texture and also slows both cooking time and digestion time. That means that they have a lower glycemic index and are thus preferable for increasing satiety, lowering the insulin response to the meal, and keeping blood sugar levels from peaking. This also results in delaying hunger so a person is less likely to snack or get overly hungry before the next meal. Here is how I like to cook oats for breakfast. Ingredients 1/2 cup Dry steel cut oats 1 cup Water (You may want a little more than a cup, experiment to your liking) 2 T Raisins (optional or replace with chopped dried apricots etc.) 2 T Ground flax meal (optional, but high in healthy n-3 fatty acids and fiber) Salt to your taste (try Lite salt to lower sodium intake) 2T Sunflower seeds or almonds 1 cup Fresh berries or a banana Directions Heat water to a boil. While water is heating, add the salt, raisins, and flax meal. When the water boils, add the steel cut oats. Stir once. Turn heat down to simmer and cook covered for 7-8 minutes. Provides two small servings. Double for large servings or small servings for 4 people. Serve and eat while hot. Add soy milk or low fat milk. Slice fresh fruit on top to add extra flavor. My wife likes banana slices. I like fresh berries, peaches, or sugar free applesauce. For extra crunch sprinkle almonds or sunflower seeds on top.

Send your message to us

Pre-painted Galvanized/Al uzinc Steel Sheet Coil with Prime Quality and Lowest Price bluee

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords