Plastic Tubes PPR Pipes for Hot and Cold Water Conveyance

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Overview

PP-R (polypropylene random) tube called type three polypropylene pipe and is also called the PP-R pipe or PPR pipe, with energy saving, environmental protection, high strength, corrosion resistance, with smooth inner wall has the advantages of scale, construction and easy maintenance, long service life, widely used in building water supply and drainage, urban drainage city gas and power cable sheath, and industrial fluid transportation, agricultural irrigation construction, municipal, industrial and agricultural fields. The PP-R pipe is made of random copolymerized polypropylene and is extruded into tubes to be molded into tubes.

Applications of PPR Pipe (white, gray):

1) Cold and hot water supply systems for civil and industrial constructions, e.g. in residential buildings, hospitals, hotels, school and office buildings, ship building

2) Drinking water systems and food industry pipe works

3) Central air conditioning system

4) Irrigating system for gardens and green houses

5) Public and sport facilities such as swimming pools and stadiums

6) For rainwater utilization systems

Packaging Details:

1. Large carton: 515 x 400x 220 Cubage: 0.04532 M3

Small carton: 390x255x250 Cubage: 0.0248 M3

2. PE poly bag+ carton Delivery Detail: 15 days/ 20" container; 25 days/ 40HQ

Product Description

1.Material : | PPR |

2.Color: | White, Gray, Green, or as you required. |

3.Size: | 20-110mm |

4.Logo: | CMAX or Customized |

5.MOQ | 500pcs |

6.Samples Time: | (1) 4-5days-If you want to customize your logo. |

(2) 1day-For our existing samples for reference. | |

7.OEM Accepted | Yes |

8.Certification available: | Yes |

9.Packing Details: | Weaving Bag |

10.Production Capacity: | 5,000,000pcs Per month. |

11.Payment Term: | (1) L/C,T/T,D/P |

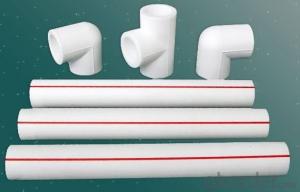

Product Show

Our Advantages:

1) Healthy, bacteriological neutral, conforming to drinking water standards

2) Resistant to high temperatures, good impact strength

3) Convenient and reliable installation, low construction expenses

4) Excellent heat-insulation property from minimum thermal conductivity

5) Lightweight, convenient to transport and handle, good for labor-saving

6) Smooth inner walls reduce pressure loss and increase flow speed

7) Sound insulation (reduced by 40% compared to galvanized steel pipes)

8) Light colors and excellent design ensure suitability for both exposed and hidden installation

9) Recyclable, environment-friendly, accords with GBM standards

- Q: Can plastic tubes be used for pet enclosures?

- Yes, plastic tubes can be used for pet enclosures. They are often used as tunnels or connecting pathways in small animal habitats, such as hamster or gerbil cages. They provide a safe and interactive environment for pets to explore and play in.

- Q: do i need to need to clean the gas tube on my ar-15?

- Russ is on to something. Peanut butter works ok but its kind of messy. Maple syrup smells better when the gas tube heats up. I drop a length of monofilament fishing line through the gas tube, tie the end to a q-tip, dip the q-tip in the maple syrup, and pull it back through. Repeat until the tube is clean.

- Q: Are plastic tubes resistant to moisture absorption?

- Yes, plastic tubes are generally resistant to moisture absorption.

- Q: How do you prevent plastic tubes from deteriorating?

- To prevent plastic tubes from deteriorating, it is important to store them properly, away from direct sunlight and extreme temperatures. Regular cleaning and maintenance should also be done to remove any chemical residues or debris that might cause degradation. Additionally, using the appropriate type of plastic for the intended application and avoiding exposure to harsh chemicals can help prolong the lifespan of the tubes.

- Q: he said something about the pressure. That being the reason he had to get new tubing.

- First okorder and type in your car and it will and you can do a search for a fuel pump and it will show you a picture and print it out and take it with you then you will know if he is trying to take your money or not I have done a few and I have never had a problem like you describe

- Q: can you use copper piping to fire firework rockets instead of plastic tubes ?

- Yes, it is better because if the tube explodes, x-rays cannot find plastic in your body but copper will show up.

- Q: Can plastic tubes be used for hydroponics?

- Yes, plastic tubes can be used for hydroponics. In fact, they are commonly used as a cost-effective and practical option for creating the necessary channels to deliver water and nutrients to the plants.

- Q: I have lots of hamster space all connected with tubes, and each area is colorful and some have wires. I have had hamsters in the past, but never more than one at a time. I want another hamster to replace the one I had for almost 4 years but then passed away. The thing is, I don't know if I should get more than one hamster at the same time, and also I don't know what kind of hamster/s I should get. Please help!

- Firstly, there is no such thing as a Teddy Bear Hamster. There are either Dwarf Hamsters or Syrian Hamsters. Teddy Bear, Fancy Bear, Panda Bear, Golden, Candy, Black Wolf, etc are just some fake names given to different coloured Syrian Hamsters to sell them at different prices. They are all the same, belonging to the Same Species. Now that I cleared that up, It depends on what you want. ?Dwarf hamsters, they are small and usually they like living in a group of 2 or 3. If you want more than one hamster, then you should go for Dwarf Hamsters. However, usually the Dwarf hamsters tend to bite ad trust their owners less, or hide when the owners approach unless they've gotten used to the owner. It may take a long time to tame them. There are exceptions, that's why I quoted the word usually. ?Syrian hamsters are of the large variety, with 2 kinds. Some have long fur and some have short fur. (The long haired Syrians are often falsely termed as Teddy Bear Hamsters). Syrian hamsters CANNOT be kept in pairs. They prefer to have their entire territory to itself. Any other hamster (considered as intruder) will definitely cause them to attack each other. I've seen it happen. The fights can be very dangerous, which can even lead to death. On the brighter side, Syrians are more friendly towards their owners and easier to tame. Yes, they do bite, only at first. They'll no longer bite once they get to know their owner. I've had 4 Syrian hamsters who loved to get out of their cages and climb on my bed and walk over me. I'd recommend ONE Syrian hamster. If your cage is large enough, the hamster will be very happy, assuming food and water being supplied and some quality time spent. (_( (=' :') --<I ? U (,()() ? -?o?'? ????-? ?- -β??? ??????- -? ?-★ ?ǐvǐ?? Я?? ★-? ??????????

- Q: Can plastic tubes be used for hydroponic gardening?

- Yes, plastic tubes can be used for hydroponic gardening. They are a popular choice for constructing hydroponic systems due to their durability, flexibility, and cost-effectiveness. Plastic tubes can be easily cut and connected to create custom layouts, allowing for efficient water and nutrient distribution to the plants. Additionally, plastic tubes are resistant to water damage and provide a sterile environment that minimizes the risk of pests and diseases.

- Q: Can plastic tubes be used for storing solvents or chemicals?

- Yes, plastic tubes can be used for storing solvents or chemicals. However, it is important to consider the compatibility of the plastic material with the specific solvent or chemical being stored to ensure there is no degradation or leakage. Additionally, it is crucial to choose tubes made from chemically resistant plastics, such as polypropylene or PTFE, to maintain the integrity of the stored substances and prevent any adverse reactions.

Send your message to us

Plastic Tubes PPR Pipes for Hot and Cold Water Conveyance

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords