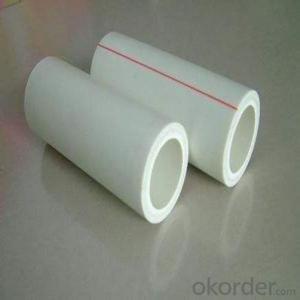

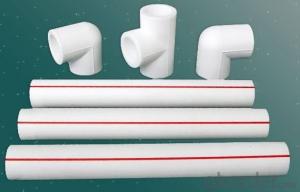

Plastic Tubes PPR Pipe for Hot and Cold Water Conveyance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Overview

Place of Origin: Henan, China (Mainland)

Model Number: PE100

Material: PE

Specification: DN 20-mm~DN1200mm

Length: According to customer requirement

Thickness:SDR11/13.6/17

Standard: ISO

Color: many colors

Product name: Plastic Pipe

Application: house and garden

Usage: Family Decoration Industry

Certification: ISO Certificate

Feature: Lightweight

Size: Customized Size

Type: Round Pipe

Name: HDPE Plastic Pipe

Connection: Butt Fusion

Main Product Features:

Large drum hub to maximize cable life

Self-activating automatic brake hold the load securely when crank handle is released

With cable or strap

Safety guard cover available

Top quality with competitive price

Widely used in the double beam bridge crane and gantry crane

Easy to install and high quality

Compact structure and reasonable design

Could be mounted on t he ground or wall!

Double drum!!

Product Description

1.Material : | PPR |

2.Color: | White, Gray, Green, or as you required. |

3.Size: | 20-110mm |

4.Logo: | CMAX or Customized |

5.MOQ | 500pcs |

6.Samples Time: | (1) 4-5days-If you want to customize your logo. |

(2) 1day-For our existing samples for reference. | |

7.OEM Accepted | Yes |

8.Certification available: | Yes |

9.Packing Details: | Weaving Bag |

10.Production Capacity: | 5,000,000pcs Per month. |

11.Payment Term: | (1) L/C,T/T,D/P |

Product Show

FAQ

Q: How do you guarantee the quality of your product?

A: Every process will be checked by responsible QC which insures every product's quality.

Q: How much is your delivery time?

A: Normally within 30 days of receipt of LC original or prepayment, but mostly according to the specific requirements or the quantity

Q: I need sample, could you support?

A: We can supply you with the sample for free, but the delivery charges will be covered by our customers. For avoiding the misunderstanding, it is appreciated if you can provide the International Express Account for Freight Collect. Also you can have a visit to us, welcome to CNBM!

- Q: How to remove the rust plastic pipe

- Just hit it with a pulse heating machine

- Q: This may be a little hard to describe but, hopefully someone can figure what im talking about.This toy is and open plastic tube with ridged edges. At one end of the tube it has a round half sphere for a handle. the toy is limp when held straight ahead. the toy is meant for swinging to the side or over ones head. the faster it twirls the higher the pitch. this has been bugging me for a while because i can not remember the name of the toy. if anyone can tell me the name of this it would really help.

- kinda looks like a small hose for the pool , maybe 2 tube and 3'-4' long

- Q: Can plastic tubes be used for oxygen delivery in medical applications?

- Yes, plastic tubes can be used for oxygen delivery in medical applications.

- Q: the tube is a 24 inch tube how do i use it onit?

- Add 4oz of the Slime sealant to the inner tube. The cap of the Slime bottle should have a tool built in that will unscrew the valve core. Once the core is out, just use the included clear plastic tube to put the slime in. When you are all finished just screw the core back in and air it up.

- Q: Are plastic tubes safe for pharmaceutical products?

- Yes, plastic tubes are generally safe for pharmaceutical products. They are commonly made from materials that are compatible with pharmaceutical compounds and can provide an effective barrier against contamination. However, it is important to ensure the quality and safety of the specific plastic material used, as well as proper storage and handling conditions, to maintain the integrity of the pharmaceutical products.

- Q: How many kinds of plastic pipe material are there?

- Metal composite plastic pipe: steady pipe (polyethylene, polypropylene and aluminum belt), aluminum plastic pipe (polyethylene aluminum belt or aluminum pipe), steel plastic composite (steel pipe or steel wire or steel band composite polyethylene).

- Q: In my vaccum cleaner, plastic hose and steel extension tube are stuck.How can i unlock them?will any product like PB blaster or any penetrating oil help.Can someone please advise..

- On the steel extension tubes you could use a touch of wd40. This may work where the tube connects to the plastic hose as well, but wd40 can have an effect on some plastics, so take care. It maybe better to use a drop of cooking oil.

- Q: What are the toxic hazards in plastic pipe production plants? What are the specific hazards?

- In such a working environment, we should pay attention to self-protection, such as the need to insist on wearing masks, regular medical examination and so on. When the temperature reaches 65 degrees centigrade, the toxic substances will precipitate and seep into the food, which can cause serious harm to the vital parts of the liver, the viscera, the kidneys, the reproductive system and the central nervous system.

- Q: Can plastic tubes be used for architectural lighting installations?

- Yes, plastic tubes can be used for architectural lighting installations. They are lightweight, flexible, and can be easily shaped and manipulated to fit various architectural designs. Additionally, plastic tubes are durable, cost-effective, and can provide diffused lighting effects, making them a popular choice for architectural lighting installations.

- Q: How are toothpaste tubes made? I know that there's polyethylene coatings on aluminum, but how to they actually made the tubes this way? I know it can't be injection molding or blow molding.

- why can't it be injected extrusion molding of the tubing followed by a bonding process?

Send your message to us

Plastic Tubes PPR Pipe for Hot and Cold Water Conveyance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords