High-Quality PPR Fitting Socket Plastic Tubes - Compliant with Food Hygiene Regulations and Non-Toxic

- Loading Port:

- Tianjin

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 9000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Features

1. Corrosion resistance

PPR pipes and fittings can resistant to most chemical corrosion; it can withstand PH value range 1-14 high concentration of acid and alkali corrosion over a wide temperature range.

2. Installation performance

PPR pipe PPR pipe is light in weight, and the operation installation is easy, which make it available to weld again. It is very important that pipe and pipe fittings can be welded together in seconds with a simple tool. Compared to traditional connection methods it can save 40%~50% of the time.

3. Safety Indicators

The basic component of PPR is carbon and hydrogen which is simple. It keeps in line with food hygiene regulations, non-toxic. If you use PPR pipe, there will no dirt in the inner wall or “secondary water pollution” caused by rust any more.PPR pipe ,green building materials, is more suitable for transporting drinking water.

Advantages of PPR pipe

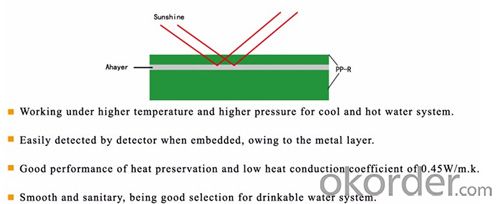

1. Maximum operating temperature can up to 95℃; it can work in a long term under the condition of 70℃ and 1.0Mpa.

2. PPR pipe density is only 1/8 of metal pipe; pressure resistance strength test is up 5Mpa, with good toughness, impact resistance.

3. Inner diameter of PPR pipe is little bigger than that of pipe fittings, which can ensure not to increase the resistance to fluid flow.

4. Inner wall of PPR pipe is smooth, no rust, no scaling, small fluid resistance

5. PPR pipe has excellent insulation properties, can significantly reduce the vibration and noise caused by the flow of liquid.

6. PPR pipe energy consumption is only 20% of steel pipe; its thermal coefficient is also only 1/200 of steel pipe, reducing heat loss greatly.

7. PPR pipe is poor electrical conductor material, which can avoid galvanic corrosion phenomena.

8. With poor thermal conductivity, PPR pipe can reduce condensation.

9. PPR pipes, fittings are recyclable.

Application

1. Hot and cold drinking water supply system of civil and industrial buildings

2. Clean, pure water piping system

3. Beverage production and transport systems

4. Industrial liquid delivery system

5. Central air conditioning system

6. Hot water circulation Heating System

7. Compressed air piping system

8. Garden and greenhouse irrigation systems

FAQ

Chemical Structure of PPR

PP random copolymer of ethylene molecules generally contain 1 7% (by weight) and 99-93% (by weight) of propylene molecules. On the polymer chain, ethylene molecules randomly inserted in the middle of the propylene molecules. In such a random or statistical copolymers, the majority (typically 75%) are single molecules of ethylene incorporated into the insert, called the X3 group (three consecutive ethylene [CH2] are sequentially arranged in the main {TodayHot} chain), which can also be seen as an ethylene molecule is inserted in the middle of two propylene molecules.

Another 25% of the ethylene molecule is inserted more incorporated into the main chain, also known as X5 groups, since there are five consecutive methylene groups (two ethylene molecules together two propylene molecules inserted in the middle). It is difficult to distinguish between X5 and higher groups such as X7, X9 and so on. In view of this, the XS and higher ethylene content groups together counted as> X3%.

Randomness ratio X3 / X5 can be measured. When the above percentage X3 group is large, it will significantly reduce the crystallinity of the copolymer, the final properties of this random copolymer influence. Ethylene copolymer has very high levels of crystallinity of the polymer, similar to the effect when high random polypropylene content.

Unlike random copolymer PP homopolymer as the polymer backbone randomly inserted into the ethylene molecules hindered crystalline arrangement of polymer molecules. Copolymers of a decreased change in crystallinity caused by physical properties: PP homopolymer and random copolymer is reduced in rigidity as compared to improve impact resistance, better transparency. Ethylene copolymers also lower melting temperature, which has become in some ways the advantages of their use.

Random copolymer may contain more leather extract and random PP, as well as a much higher ethylene content of the polymer chain. This higher leather extract content may, depending on the polymerization process, to varying degrees in all the goods copolymer materials and meet the Federal Food Administration (FDA) on food contact {HotTag} specified on the cause difficult.

Manufacturing method of PPR pipes:

Ethylene / propylene random copolymer and ethylene molecules is carried out by polymerization of propylene molecules simultaneously obtained, the use of the reactor and the production of PP homopolymer same. Ethylene propylene molecular ratio of small molecules is faster than the reaction (reactive approximately ten times) propylene. This stereospecificity of the catalyst activity is increased and decreased, resulting in increased generation amount of atactic polypropylene. In order to reduce the generation of such random thereof, the reaction temperature needs to be reduced, thereby reducing the activity of the catalyst, and to reduce the content of the final product ppr sizes random isomer, to obtain a product having a more balanced performance.

Ethylene content (> 3%) random copolymer in the production process more difficult to deal with, it is difficult to carry out polymerization in hexane diluent, since the two by-products of the reaction (the amount of atactic polypropylene and ethylene-containing high copolymer) can be dissolved in hexane. This bulk liquid propylene polymerization reaction is the same, in spite of low solubility. Diluted with hexane to produce a large number of process by-product, it must be separated out in hexane in the recycle phase, which will increase the total cost of production, but was able to get close sparingly soluble polymer component of the cleaner. In the bulk polymerization process, these impurities will remain in the polymer, and trouble in handling sheet-like material. Moreover, the final copolymer products contain more soluble impurities. Second washing with an organic solvent, most of the impurities can be removed, but will increase the overall cost of production of the copolymer. In general, a high content of by-products, the flake random copolymer will become more viscous, when the ethylene content higher than 3.5% (by weight), the problem is more prominent.

- Q: How do plastic tubes compare to metal tubes?

- Plastic tubes generally offer advantages such as lower cost, lightweight nature, and resistance to corrosion, while metal tubes tend to provide better durability, higher strength, and increased temperature and pressure resistance. The choice between plastic and metal tubes depends on the specific application requirements and priorities.

- Q: What is the expansion joint in the drain pipe?

- Expansion joint is also called expansion jointLong distance pipes also have expansion and contraction when there is temperature change

- Q: my whole family has forgorten what they are called and i want to buy one

- Gerbles

- Q: 2-3/4long by 1 diameter, with rounded resealable water tight plugs. Shaped like a test tube.

- please go to the near your shopping mall and you find out plastic all kind of tubes.

- Q: I got a new syrian hamster two and a half days ago, he has a big wire two storey cage with plastic tubes connecting the upstairs and downstrairs, he's spent mostly all of his time in the tube, taking all the bedding from his little house and his food in it and pooing a lot, I mean the tube is full of poo mixed with food and bedding. (I know this is normal) he's still really shy, he spooks easily, and he's not even been on his wheel yet but he's slowly coming around to me when I hand feed him, I haven't touched him yet though, just leaving him to it for a few days. Should I clean his tubes or is it too early? I don't want to stress him out but I read you are supposed to clean his cage every week and spot clean and clean his toilet area every day and his tubes are his toilet area and I'm seriously not joking when I say he poos a lot.

- I think that you should probably clean it out. Do it at night when he is not in the tubes so you do not disturb him. My hamster sleeps in an attachment that goes on the tubes and she does the same thing with the food, pooping, and peeing in there. She loves when I clean it out for her, I do it about every 2-3 days. If I do not clean it out and wait an extra day if I am busy or something she takes all of the bedding out of it and moves it to the regular cage area herself. So yes I do think that you should clean it, he will probably appreciate it!

- Q: I am looking for paint that I can use on flexible plastic tubing that won't peel or crack. Any ideas?

- This Site Might Help You. RE: I am looking for paint that I can use on flexible plastic tubing that won't peel or crack. Any ideas?

- Q: just curious about commerce. . .

- Because they are not making plastic tube radios anymore. Human bones are made all the time.

- Q: Are plastic tubes resistant to warping under high temperatures?

- No, plastic tubes are not typically resistant to warping under high temperatures.

- Q: This Saturday I'm going tubing in the Guadalupe River and I'm FREAKING out. I know how to swim but I'm just scared of waterfalls and really rough and tough water. Any information about the rivers currents and the flow will be nice. Also any advise would be greatly appreciated. (The cfs is currently 68 if that is important)

- EXCELLENT tubing on the Guadalupe River in New Braunfels. Rented hard plastic bottom tubes (once you get to the mini rapids, you'll be glad you got the hard bottom to save your butt from pain) to go down this awesome natural lazy river. Rented the tubes from Rockin R Rivers tubes off of Gruene in New Braunfels. So fun. They pick you up at one of two different spots down the river in a caravan, so you don't have to worry about getting back. You can bring a cooler with non trash items, food, and toys. We had a cooler float, drinks, food, and our beach jai alai game It was just across the river from the bed n breakfast we stayed at. The Gruene Hotel. And right next to the fantastic restaurant Gristmill River Restaurant Bar

- Q: What is the level of flexibility of plastic tubes?

- Plastic tubes have a high level of flexibility, allowing them to be easily bent, twisted, or stretched without breaking.

Send your message to us

High-Quality PPR Fitting Socket Plastic Tubes - Compliant with Food Hygiene Regulations and Non-Toxic

- Loading Port:

- Tianjin

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 9000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords