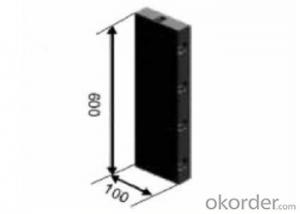

PP Hollow Concrete Template(1830*915*15mm)

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PP Hollow Concrete Template:

Standard measure:1830*915*15mm,other size can be customized.

National Patent,Authority Attestation,Quality Assurance.

Wear-resisting,Corrosion resistance.

Nonabsorbent,nondeformable.

Environmental protection.

Recycling and reuse,repeated times more than 30 times.

Small deformation, high stiffness, bearing capacity is strong.

Can be processing, can be saw, plane, can be nailed.

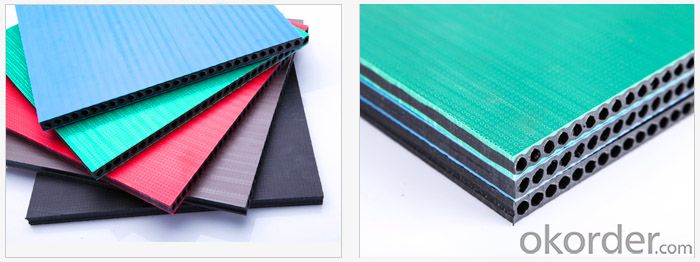

One smooth surface,and one decorative pattern surface.

Smooth surface can make the concrete tamping body smooth and level off, without secondary plaster, save material and time, reduce the cleaning and maintenance cost, used in damp environment such as basement and bridge piers.

Decorative Pattern is helpful to combine with plaster layer, special diffuse reflection effect of the light, avoid strong light reflection.

Comprehensive use of cost :Kaili Lang PP hollow concrete template than ordinary wooden template can save more than 30%.

Item | Kaili Lang PP Hollow Concrete Template (A) | Ordinary Wooden Template (B) | Ordinary Bamboo Template (C) | Comparative advantage |

Thickness(mm) | 15 | 15 | 15 | Equal |

Weight(kg/㎡) | ≦10 | 11.6 | 12.7 | A better than B\C |

Repeated Times | 30-40 | 3-5 | 4-7 | A better than B\C |

Impact Strength | High | Low | Low | A better than B\C |

Range of Application | Wall\Pillar\Girder\ Slate\Bridge | Wall\Pillar\Girder\Slate | Wall\Pillar\Girder\Slate | A better than B\C |

Surface Quality | Flat and Glabrous | Roughness | Roughness | A better than B\C |

Efficiency of Construction | High | Low | Low | A better than B\C |

Abrasive Resistance | Antiwear | No Wear | No Wear | A better than B\C |

Recyclable | Yes | No | No | A better than B\C |

Maintenance Charge | None | A Release Agent is required | A Release Agent is required | A better than B\C |

Corrosion Resistance | Acid and Alkali Resistant | No | No | A better than B\C |

Drop Test(10m) | Not Broken | Broken | Broken | A better than B\C |

Hydroscopicity & Deformation | Nonabsorbent & Nondeformable | Water Absorption & Deformation | Water Absorption & Deformation | A better than B\C |

Environmental Pollution | No Pollution | Pollution | Pollution | A better than B\C |

Advantages of hollow plastic construction templates

Stable product quality

The new hollow plastic construction templates produced by Kaili Lang Technology have canonical size, less deformation, high stiffness, strong bearing capacity, acid/alkali resistance. It will not be deformed after long time’s immersion of water, and can make the quality of architectural structure more stable. Both of architectonic size’s accuracy and the concrete’s qualified rate which adopted by the new hollow plastic building construction template system are above the national standard.

Energy-Efficient Innovation

The new hollow plastic construction template produced by Kaili Lang Technology adopts different surface treatment technology which can make templates have smooth and pattern side in the same time. It can meet fair-faced decoration requirement and save the cost of two coat work if we use smooth side during our construction; If we use pattern side, we can not only met the fair-faced decoration requirement, but also reduced the thickness of floated coat because the pattern increased the binding between concrete and floated coat. It simplified the construction difficulty and made assembly and disassembly of components more easy and simple. Thus the technical requirement for workers is not high, and there’s no dependence of equipments. There’s also no need of brushing release agent, which has greatly improved the efficiency, shortened the construction period, reduced the manpower cost and saved the material cost.

Economic benefit

The new hollow plastic construction templates produced by Kaili Lang Technology turnover time can more than 30 times, which reduced 12% work compared to the traditional wood templates. The comprehensive cost can reduced more than 30% and obviously reduced the usage of construction material such as river sand, wood, cement, and reduced the production of construction waste. It have paid an unprecedented role in energy saving and emission reduction.

Social benefit

In present, most templates used in Chinese building engineering are wooden templates. In 2011, wooden templates’ market scale has more than 300 million square meters, which need to cut 16 million trees whose diameter is more than 750px. It means to use 10,000 hectare to meet the market demand for wood templates. With the continuous increase of building quantity, which also increased at the rate of at least 10%, the massive usage of wooden templates not only destroys forest resources, but the subsequent waste will cause the secondary environmental pollution. The new hollow plastic construction templates produced by Kaili Lang Technology adopt high-tech production process. All product raw materials are from the production and processing of secondary materials. All obsolete templates after clients’ use can be recovered and reused, which means a real energy and environmental revolution.

- Q: Plastic construction template has no one used? How about the effect of using. How much can the main savings? Can really use 50 times?

- This is mainly to see how the use of workers in the process of operation by standard, 50 times is entirely possible. The use of plastic templates a little bit, the most important thing is to focus on cost savings, integrated plastic template cost is the lowest. But the price is more expensive than the wood template, long-term, large-scale use is cost-effective.

- Q: I am a novice, do this product development, and now design a set of products, and now take the product to open the mold, it is not clear what kind of material template selection! Please advise experts who look

- You do not explain your product is to open a metal mold or plastic mold, the two mold materials are not the same! I do plastic mold, we mainly use the factory S136 quenching material as a mold material, the slider generally use 718. And you also have the output of the product requirements of the mold, the production will choose a better point of the material.

- Q: Who used it, how not universal.

- 4. The product pouring concrete surface smooth, bright as a mirror, to meet the requirements of decorative and decorative water, eliminating the need for secondary plastering process. 5. Turnover times more than 50 times, the template each time the amortization cost is less than 3 yuan, steel frame plastic template turnover times more than 300 6. The material is non-toxic, harmless, pollution-free, 100% recovery, green products The 7. The product acid, alkali, anti-corrosion performance. Product use temperature of -80 ℃ ~ 100 ℃, good weather resistance.

- Q: Does the building plastic template use it? How's the effect? Can I use 30 to 50 times? Can the fire protection requirements of the steel plate on the cast-in-place plate be achieved?

- I used, hand drawing is very convenient, can use hundreds of times, made of plastic

- Q: We have to start the construction site immediately, and have not used this plastic building template; I would like to ask you all the big brother who used this plastic building template ah? How is the quality of ah? So good ah?

- We use the pp building template. The effect is also good, top about. They also recycle the plastic building template we used for 3 tons for 1 ton.

- Q: Types of building templates? What is the water template?

- Building a template, the use of rear surface roughness is better, do not need to deal with the second. Provincial workers, time-saving.

- Q: Plastic mold dynamic template, the size of the template

- Did not you understand what you mean? The dimensions of the mold are based on your mold design, the more product positioning, the greater the shape of the mold.

- Q: Is there a kitchen toilet to seal the water pipe plastic template? Where to sell?

- Hardware stores have, any one hardware store can buy, you can buy the nearest.

- Q: What is the economic benefits of building wood formwork compared to plastic molds?

- In summary, what template to use depends on what your structure needs.

- Q: The price of raw materials can say better, is the PVC material.

- Usually in square meters. But whether by square meters or by weight count, but the process is different, but the results will be the same unit price. Off to know how much the cost of this product, how much profit. The cost of each product produced by the factory are not necessarily, of course, the profit is not the same. Cost is the material, management, plant rent, utilities, machine depreciation and other costs together, and now PVC materials have different grades, the specific price can be found on the Internet to see.

Send your message to us

PP Hollow Concrete Template(1830*915*15mm)

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords