Pot En Geotextile with CE Certificate 200g Nonwoven

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

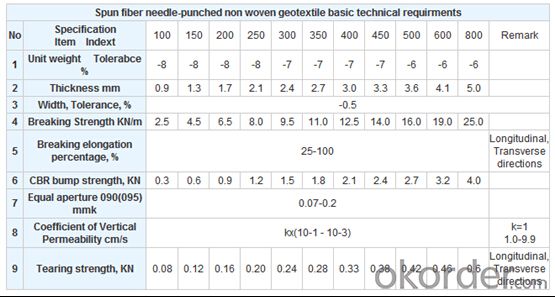

Specification

Nonwoven Geotextile

Geotextile Description

Filament yarn with polyester filament geotextile acupuncture non-woven geotextile, there is a polyester filament geotextile after high-speed needle acupuncture and into cloth products, do not contain chemical additives in the process of needle, also without heat treatment, is environmentally friendly building materials.Can replace the traditional engineering materials and construction methods, construction is more secure, and contribute to environmental protection, can be more economic, effective and lasting to solve basic problems in engineering construction.

Specification

Property:

1. Good flexibility, resistant to corrosion, resistant to acids and alkalis, anti-oxidation.

2. Separation, filtration, drainage, reinforcement, protection, and maintenance function.

Application:

1. Water conservancy project and hydropower project.

2. Road paving, railway.

3. Airport and port.

4. River bank protection and tunnel

5. Environmental protection, etc.

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 sqm.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q: Heap half a month later in the mound inside dug a tree tree hole, a heavy rain, a region which has two trees in the area of water, to several days of talent, which is normal, please expert advice, More

- If the plant, need to shop the root layer, I guess you ignore this point, and pay attention to observe, I wish you good luck! Hope to help you.

- Q: Will you master knitting reinforced geotextile H and reinforced geotextile What is the difference? In addition, how to distinguish between spunbond and weaving in reinforced geotextiles? More

- Texture and material ratio is different ah.

- Q: What are the key differences between woven and nonwoven geotextiles?

- The key differences between woven and nonwoven geotextiles lie in their manufacturing processes and physical characteristics. Woven geotextiles are made by interlacing yarns or fibers together to create a stable and strong fabric. On the other hand, nonwoven geotextiles are produced by bonding or felting fibers together without any weaving process. In terms of physical characteristics, woven geotextiles generally have higher tensile strength and puncture resistance due to their interlaced structure. They also offer better filtration properties as the open spaces between the woven yarns allow for effective water flow. Nonwoven geotextiles, however, have a higher permittivity, meaning they have a greater ability to allow water to pass through. Another notable difference is their durability. Woven geotextiles tend to be more resistant to UV degradation and offer better long-term performance, making them suitable for applications that require high strength and stability over time. Nonwoven geotextiles, although less durable, are often used for short-term projects or where filtration and separation are the main requirements. Overall, the choice between woven and nonwoven geotextiles depends on the specific application and desired properties. Woven geotextiles are typically favored for their strength and longevity, while nonwoven geotextiles are preferred for their filtration capabilities and cost-effectiveness in certain applications.

- Q: Performance and Application of Impervious Geotextile

- Anti-seepage geotextile has excellent water permeability, filterability, durability, can be widely used in railways, highways, sports museum, dams, hydraulic construction, then hole, coastal beach, reclamation, environmental protection and other projects. Mainly staple acupuncture non-woven geotextile and split film woven geotextile. Anti-seepage geotextile function: 1. The use of geotextiles good permeability and water permeability, so that water through, so as to effectively remove the loss of sand. 2. Geotextile has a good water conductivity, it can form a drainage channel within the soil, the soil structure of the excess liquid and gas efflux. 3. Using geotextile to enhance the soil tensile strength and resistance to deformation, enhance the stability of the building structure to improve the quality of soil. 4. Effective focus will be concentrated diffusion, transmission or decomposition, to prevent soil damage by external forces. 5. to prevent the upper and lower gravel, soil and concrete mixed between. 6. Mesh is not easy to plug - due to the formation of amorphous fibrous tissue structure and strain and mobility. 7. High permeability - under the pressure of soil water, can still maintain a good permeability 8. Corrosion resistance - to polypropylene or polyester and other chemical fiber as raw materials, acid and alkali, no corrosion, no moth, antioxidant. 9. Construction is simple - light weight, easy to use, simple construction. Anti-seepage geotextile characteristics High anti-puncture strength, large coefficient of resistance to aging performance, to adapt to the environmental temperature range Excellent excellent anti-drainage performance for water conservancy, chemical, construction, transportation, subway, tunnel, garbage disposal and other projects

- Q: How do geotextiles contribute to environmental sustainability?

- Geotextiles contribute to environmental sustainability by providing erosion control, improving soil stability, and promoting vegetation growth. They help prevent soil erosion by acting as a barrier against the forces of wind and water, reducing the sedimentation of water bodies and preserving the quality of nearby ecosystems. Geotextiles also enhance soil stability by reinforcing weak soils, reducing the need for extensive excavation or replacement. Moreover, they facilitate the establishment of vegetation, promoting biodiversity and restoring natural habitats. Overall, geotextiles play a crucial role in mitigating environmental degradation and supporting sustainable land management practices.

- Q: What are the challenges associated with the installation of geotextiles?

- Some challenges associated with the installation of geotextiles include ensuring proper alignment and placement of the fabric, securing it to the ground to prevent shifting or movement, and properly overlapping and connecting multiple pieces of geotextile to create a continuous barrier. Other challenges may include dealing with uneven or unstable soil conditions, working in difficult terrain or access areas, and ensuring the geotextile does not get damaged during the installation process. Additionally, the selection and installation of appropriate anchoring methods and the need for specialized equipment or expertise can also pose challenges.

- Q: JTGF80 / 1-2004 "standard" 4.5 Geosynthetics in the treatment of the measured items in the "anchoring length", in the construction design diagram, the provisions of the value of the allowable deviation should be how to implement? Question added: Sorry! I missed a few words. When the construction design is not indicated, the specified value, the allowable deviation value should be implemented? JTGF80 / 1-2004 "standard only write to meet the design, construction requirements. I did not say that the design of the length of the anchorage is how much, can not find the construction technical specifications. So I do not know the provisions of the value of how to allow deviation? More

- Specifically not less than the specified value, does not exceed the allowable deviation. This is the so-called construction by specification! You refer to JTG assessment standard -2004 is correct! I have the data to let you refer to the next / geogrid and geotextile landscape is greater than or equal to 50cm, vertical is greater than or equal to 150com

- Q: How are geotextiles used in civil engineering projects?

- Geotextiles are commonly used in civil engineering projects for various purposes such as soil stabilization, erosion control, drainage management, and filtration. These synthetic fabrics are placed in the soil to reinforce it, prevent erosion, filter water, separate different layers of soil, and improve the overall performance and longevity of the project. They are versatile, cost-effective, and environmentally friendly solutions that help enhance the stability and functionality of civil engineering structures like roads, embankments, retaining walls, and landfills.

- Q: What is geotextile, what role

- Geotextile is a new type of building materials, raw materials are polyester, acrylic, nylon and other polymer polymer synthetic fiber. In accordance with the manufacturing method is divided into: there are two types of geotextile and non-woven geotextile. Geotextile with anti-seepage, anti-filtration, drainage, isolation, reinforcement, protection, sealing and other functions, it with the conventional masonry and concrete material seepage effect compared to a low investment, simple construction process, short duration Infiltration effect is good, the channel effective use of high coefficient. Water conservancy engineering dams and slope protection filter, channel isolation, seepage control; road, railway, airport runway foundation isolation, filter, drainage, slope, retaining wall and road reinforcement, drainage; , Geotextile has been widely used in the field of infrastructure construction, and has been gradually applied in the field of infrastructure construction, and the use of geotextile In a wider area.

- Q: How are geotextiles used in sports field construction?

- Geotextiles are used in sports field construction to enhance the stability, drainage, and longevity of the playing surface. They are commonly installed beneath the turf to provide separation between the subbase and the playing surface, preventing the migration of fines and ensuring proper filtration of water. Geotextiles also help to distribute loads evenly, reduce soil compaction, and prevent the formation of ruts and depressions on the field. Overall, geotextiles play a crucial role in creating high-performance and durable sports fields.

Send your message to us

Pot En Geotextile with CE Certificate 200g Nonwoven

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords