Portland® Steel Wire Cord Belt Clamping Connection Joint Device Assembly

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 99 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

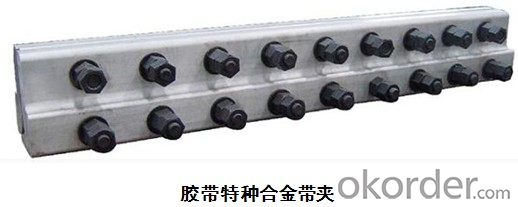

The steel wire cord belt clamping connection joint device, of the belt bucket elevator includes special aluminum alloy material belt clamps and

Portland special belt joint curing material. It is an important vulnerable part of the belt elevator and has completely replaced the imported products

in China.

The belt joint clamp is made of special alloy materials, which reduces the weight of ordinary metal clamp by 60% compared with that of

ordinary metal clamp. Various technical indexes and comprehensive properties such as hardness, toughness, tensile strength and fatigue resistance

are the same as some German products.

Belt Special Alloy Band clamp

The adhesive steel wire cord belt joint is locked with special curing material, and the steel wire, steel wire clamp and belt clamp box at the end

joint of the adhesive belt are solidified into a whole, so that there is no hidden danger of displacement or falling off between the belt clamp and the

adhesive belt, and the adhesive belt joint is safer and more reliable.

Special fastening glue

- Q: Including welding machine, wire, wire, fast joint, tungsten needle, tungsten pole clamp, connecting body, porcelain Tsui and cutting machine brand, cutting machine with accessories brand, the more all the better.I'm welded with a thick wall of 1.0-3.0 boards or tubes, sometimes thicker or thinner. Welding machine and plasma cutting machine I used Ruiling and Matsushita, Matsushita is better, but slightly more expensive. The domestic machine in the field of welding inverter Ruiling is big, but also lower heat stability. Whether domestic or joint ventures, imported machines, users know more affordable machine, or value for money machine?Accessories are consumables, quality is very important, so I want to know what brand everyone will use, I think it will be better and cheaper. Thanks to enthusiastic netizens, your answer is too simple.I think this question is understood as communication, and I hope everyone can do something better. Of course, the starting point for asking questions was myself.

- For the thin stainless steel to avoid leakage welding welder for small current, Matsushita welder then I recommend you use the pulse welding Matsushita, after welding, thermal deformation, and relatively easy to achieve the quality of silver white weld. Inverter welding machine in fact, the control is still a bit worse, just higher than the silicon welding machine, but on the way of welding, also belongs to short-circuit transition, how can compare with the spray transition? The choice of welding wire is very important, it is necessary to select stainless steel wire according to the base material. To sum up, welding machine, Panasonic 350GL3, welding wire, Issa or Olin can choose. PS had better use 0.8 wire.

- Q: What kind of welding rod is good for welding machine parts?

- Ordinary material steel use 502 of it

Send your message to us

Portland® Steel Wire Cord Belt Clamping Connection Joint Device Assembly

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 99 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

CNBM (Hefei) Electromechanical Engineering Technology Co., Ltd.

CNBM (Hefei) Electromechanical Engineering Technology Co., Ltd.