Aerospace Grade Polycrystalline Solar Cells - High Efficiency, Low Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 8000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief Introduction of Solar Cells

A solar cell, is an electrical device that converts the energy of light directly into electricity by the photovoltaic effect, which is a physical and chemical phenomenon. It is a form of photoelectric cell, defined as a device whose electrical characteristics, such as current, voltage, or resistance, vary when exposed to light. Solar cells are the building blocks of photovoltaic modules, otherwise known as solar panels.

Polycrystalline Silicon Solar Cells Advantage:

• High efficiency and stable performance in photovoltaic conversion.

• Advanced diffusion technique ensuring the homogeneity of energy conversion efficiency of the cell.

• Advanced PECVD film forming, providing a dark blue silicon nitride anti-reflection film of homogenous color and attractive appearance.

• High quality metal paste for back surface and electrode, ensuring good conductivity, high pulling strength and ease of soldering.

• High precision patterning using screen printing, ensuring accurate busbar location for ease with automatic soldering a laser cutting.

Usage of Polycrystalline Solar Cells

Solar cells are often electrically connected and encapsulated as a module. Photovoltaic modules often have a sheet of glass on the front (sun up) side, allowing light to pass while protecting the semiconductor wafers from abrasion and impact due to wind-driven debris, rain, hail, etc. Solar cells are also usually connected in series in modules, creating an additive voltage. Connecting cells in parallel will yield a higher current; our solar cells have passed IEC Certification. With high and stable quality, our cells can greatly improve the performance of Solar Modules.

Specification:

Mechanical data and design |

Format - 156 mm × 156 mm ± 0.5 mm |

Thickness- - 200 μm ± 20 μm |

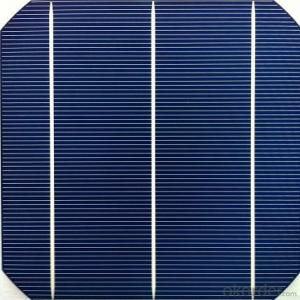

Front (-) - 1.4 mm bus bars (silver),blue anti-reflection coating (silicon nitride) |

Back (+) - 2 mm wide soldering pads (silver) back surface field (aluminium) |

Temperature Coefficient of Cells |

Voc. Temp .coef.%/K -0.364%/K |

Isc . Temp .coef.%/K +0.077%/K |

Pm. Temp. coef.%/K -0.368%/K |

Polycrystalline 156x156mm 3BB | ||||||

EFF Code | EFF. (%) | Pmax(W) | Impp(A) | Vmpp(V) | Isc(A) | Voc(V) |

1760 | 17.60 | 4.28 | 8.060 | 0.531 | 8.610 | 0.633 |

1740 | 17.40 | 4.23 | 8.030 | 0.524 | 8.570 | 0.632 |

1720 | 17.20 | 4.19 | 8.000 | 0.522 | 8.510 | 0.631 |

1700 | 17.00 | 4.14 | 7.850 | 0.521 | 8.490 | 0.622 |

1680 | 16.80 | 4.09 | 7.770 | 0.521 | 8.390 | 0.620 |

1660 | 16.60 | 4.04 | 7.650 | 0.519 | 8.350 | 0.615 |

1640 | 16.40 | 3.99 | 7.580 | 0.516 | 8.290 | 0.615 |

Intensity Dependence |

Intensity [W/m2] Isc× [mA] Voc× [mV] Pmpp |

1000 1.00 1.000 1.00 |

900 0.90 1.000 0.90 |

800 0.80 0.99 0.80 |

500 0.50 0.96 0.49 |

300 0.30 0.93 0.29 |

200 0.20 0.92 0.19 |

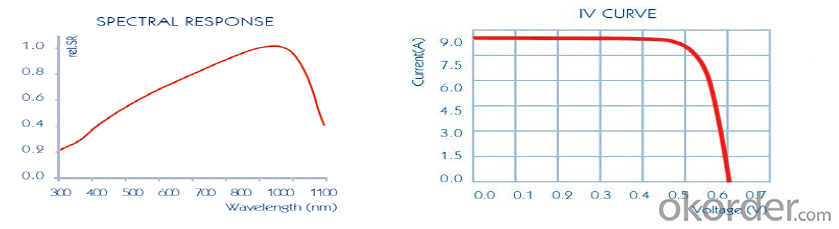

IV Curve

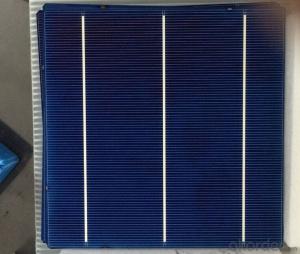

Solar Panel Images:

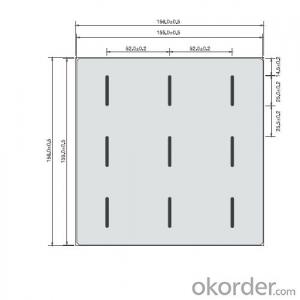

Packaging & Delivery of Polycrystalline Solar Cells

Carton Box Package and Deliver by air. It should be noticed that it should be avoid of water, sunshine and moist.

Faq

We have organized several common questions for our clients,may help you sincerely:

1. What’s price per watt?

A: It’s depends on the quantity, delivery date and payment terms of the order. We can talk further about the detail price issue. Our products is high quality with lower price level.

2. Can you tell me the parameter of your solar cells?

We have different series of cells with different power output, both from c-si to a-si. Please take our specification sheet for your reference.

3. How do you pack your products?

We have rich experience on how to pack the panels to make sure the safety on shipment when it arrives at the destination.

4. Can you do OEM for us?

Yes, we can.

5. How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The perfect time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

Silicon is the ideal material for solar cells, which is the silicon-based solar cells the main reason. But with the development of new materials and related technologies continue to develop, with other material-based solar cells are also showing more and more attractive prospect.

N-type Crystalline Solar Cell

In the bottom plate of the N-type semiconductor solar cell, a greater resistance to impurities, easier to improve the energy conversion efficiency, in theory, the attenuation rate is relatively low, but the process is more complex and costly. Pentavalent element incorporated in pure silicon crystal (such as phosphorus, arsenic, antimony, etc.), so as to replace the position of the crystal lattice of silicon atoms to form a N-type semiconductor.

At present, has reached large-scale production of N-type silicon solar cells, there are three, namely, Japan's Matsushita N-SiHITN type silicon solar cells, the United States SunpowerIBC structure N-type silicon solar cells, as well as Yingli Panda N-type silicon cells. In market share, the International Technology Roadmap for PV (ITRPV) Expected N-type Crystalline Solar Cell from 2014 up to 18% in 2020 to 50% left and right.

N-type Crystalline Solar Cell industry level: 21% -24%

P- type Crystalline Solar Cell

In the bottom of the P-type semiconductor solar cells, low cost, high attenuation rate, 25 years after the decay rate can reach 15-20%. Incorporation of trivalent elements (such as boron) in pure silicon crystal, so that the position of substitution of silicon atoms in the lattice to form P-type semiconductor.

Industrialization Level - Domestic: 18.7% -19.2% overseas: 19.2% -20%

Battery Polycrystalline

Polycrystalline silicon solar cells combines the high conversion efficiency monocrystalline silicon cells and preparation of amorphous silicon thin film materials as well as long-life battery, etc. relatively simplified new generation of batteries, the conversion efficiency is generally about 12%, slightly lower than the silicon solar cells, there is no obvious efficiency recession, and may be prepared on an inexpensive substrate material, the cost is much lower than silicon cells, and more efficient than amorphous silicon thin film batteries.

Industry level: 17% -17.5%

- Q: What is the impact of electromagnetic interference on solar cell performance?

- Electromagnetic interference can have a significant impact on solar cell performance. It can disrupt the normal operation of solar cells by introducing unwanted electrical signals that interfere with the proper functioning of the cells. This interference can lead to decreased efficiency and power output of the solar panels, as well as potential damage to the cells themselves. Therefore, it is crucial to minimize electromagnetic interference to ensure optimal performance and longevity of solar cells.

- Q: Can solar cells be used in mountainous regions?

- Yes, solar cells can be used in mountainous regions. While mountainous regions may present challenges such as variable weather patterns and shadows from the surrounding landscape, solar cells can still effectively harness solar energy in these areas. With proper design and installation, solar panels can be angled and positioned to maximize sun exposure, allowing them to generate electricity even in mountainous terrain. Additionally, advancements in solar technology, such as more efficient and flexible panels, make it increasingly feasible to utilize solar energy in challenging geographical locations.

- Q: Can solar cells be used for indoor lighting?

- Yes, solar cells can be used for indoor lighting. However, it is important to note that solar cells require sunlight to generate electricity. To use solar cells for indoor lighting, additional equipment such as batteries or capacitors are needed to store the energy generated during daylight hours and power the lights when sunlight is not available.

- Q: How do solar cells handle electromagnetic pulses?

- Solar cells are generally not designed to handle electromagnetic pulses (EMPs) as they are vulnerable to the high-intensity and short-duration bursts of electromagnetic radiation. EMPs can cause significant damage to the delicate components of solar cells, such as the semiconductor materials and electrical connections, leading to a decrease in their efficiency or even complete failure. However, certain protective measures can be taken, such as shielding the solar panels or using surge protectors, to minimize the potential impact of EMPs on solar cells.

- Q: How do solar cells impact energy security?

- Solar cells positively impact energy security by providing a reliable and sustainable source of electricity. As they generate power from sunlight, solar cells reduce dependence on fossil fuels, which are finite and contribute to environmental degradation. By diversifying the energy mix and promoting renewable energy adoption, solar cells enhance energy resilience and reduce vulnerability to price fluctuations and supply disruptions. Additionally, solar cells can be deployed in remote areas, increasing access to electricity and improving energy security for off-grid communities.

- Q: What is the impact of solar cells on wildlife?

- Solar cells have a minimal impact on wildlife as they do not produce any direct pollution or emissions that could harm animals. However, the installation of solar farms can disrupt natural habitats and affect local wildlife by altering the landscape and reducing available space for vegetation and animal species. Implementing proper planning and wildlife-friendly measures during the construction and operation of solar farms can help mitigate these potential impacts and create a more harmonious coexistence with wildlife.

- Q: How do solar cells impact the local economy?

- Solar cells have a positive impact on the local economy by creating new job opportunities in the solar industry, attracting investments, and reducing energy costs for businesses and households. Additionally, the installation and maintenance of solar panels contribute to local economic growth and stimulate the development of a sustainable and resilient energy infrastructure.

- Q: What is the role of solar cells in solar-powered water heaters?

- The role of solar cells in solar-powered water heaters is to capture sunlight and convert it into electricity. This electricity is then used to power the heating element or pump in the water heater, allowing it to heat water using clean and renewable energy from the sun.

- Q: Can solar cells be damaged by hail or strong winds?

- Yes, solar cells can be damaged by hail or strong winds. Hailstones can impact and crack the surface of the solar panels, impairing their efficiency or causing complete failure. Similarly, strong winds can potentially dislodge or break the panels, leading to damage or displacement. It is important to ensure proper installation and maintenance to protect solar cells from these potential hazards.

- Q: Can solar cells be used in telecommunications?

- Yes, solar cells can be used in telecommunications. They can provide a reliable and sustainable source of power for telecommunication equipment, especially in remote or off-grid areas where access to electricity may be limited. Solar cells can be utilized to charge batteries or directly power telecommunication systems, ensuring continuous operation and reducing reliance on traditional energy sources.

Send your message to us

Aerospace Grade Polycrystalline Solar Cells - High Efficiency, Low Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 8000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords